Satellite TV Company Manager Dies While Preparing Pickup Truck for Transport

Iowa Case Report: 03IA036

Report Date: August 2, 2004

Summary

During the summer of 2003, a 28-year-old employee for a satellite TV company was killed while preparing a vehicle for transport. He was towing an older pickup truck behind his company truck, using a tilt-bed tow dolly. He had already towed the vehicle for a short distance and needed to make final preparations for highway travel. He had just visited and interviewed a man about a job with his company. He then drove to the man’s residence to borrow some tools to make the necessary changes to the truck-in-tow. He had mentioned that the truck did not trail well, and he wanted to re-position it on the dolly. When the injury occurred he was working under the truck-in-tow, disconnecting the drive shaft. The straps securing the front wheels to the dolly were disconnected. The automatic transmission was in the park position and the parking brake foot pedal was engaged, but it was found to be defective. There were no wheel chocks or other means to secure the vehicle in place. When he removed the last bolt attaching the drive shaft to the differential, the truck immediately rolled backwards down the ramp and pinned him in the chest area to the ground causing asphyxiation. The other man tried unsuccessfully to push the truck back up the ramp, then ran to his garage to get a floor jack while his wife called 911. He was unable to raise the truck off the victim, and had to wait for rescue to arrive, which took only five minutes. The rescue crew used the Jaws of Life and cribbing to raise the vehicle off the man, but he was declared dead when taken to a helicopter site.

|

|

Photo 1 – Side view from the street showing both trucks and the 2-wheeled dolly.

|

Recommendations based on our investigation are as follows:

- Employers must provide proper safety training for employees who transport company vehicles, including how to safely remove drive shafts on vehicles-in-tow.

- Employers should provide proper tools and wheel chocks with vehicles that are used to tow other vehicles.

- Manufacturers of tow dollies should provide reliable locking mechanisms and clear instructions how to safely load, unload, and transport vehicles.

Introduction

During the summer of 2003, a 28-year-old employee for a satellite TV company was killed while preparing a truck for towing. The Iowa FACE program was notified the same day from local news, and began an investigation. Information was gathered from newspapers, the county Sheriff and Fire Departments, the State Medical Examiner, and company interviews. Photographs of the scene were also obtained. On-site FACE investigations were not conducted.

The employer is a regional satellite TV company serving a three state area (Iowa, Nebraska, and Kansas) for a large national satellite TV company. The regional company provides customer service and installations in homes and businesses and has about 130 employees. The victim worked as a manager for the regional company. Details about the company’s safety training program or specific written policies were unavailable, as company representatives were unwilling to talk further about this incident.

|

|

Photo 2– Closer view of the dolly showing hold-down straps on the ground and position of the vehicle-in-tow.

|

Investigation

The victim had traveled to interview a prospective new employee and to transport a pickup truck from the same area back to the company headquarters. This 15-year-old truck had been used by a former employee, and was running poorly, so it was being towed back to the company shop for repairs. The victim was driving a newer company pickup truck, pulling a tiltbed dolly for towing. He had used this dolly about 20 times and was quite experienced operating it. The victim had loaded the truck on the dolly and towed it to the interview location. After the interview, he asked where he could borrow some tools to work on the truck-in-tow before he left town.

The truck-in-tow had an automatic transmission and rear wheel drive, so the drive shaft had to be disconnected to prevent damage to the transmission at highway speeds. Apparently, it had not been disconnected initially when the truck was loaded onto the dolly. The victim had also mentioned that the truck was not riding well on the dolly, and he needed to reposition the truck before he left. The other man lived in the area, and he volunteered use of his tools at his residence, and the men traveled to his home to work on the truck.

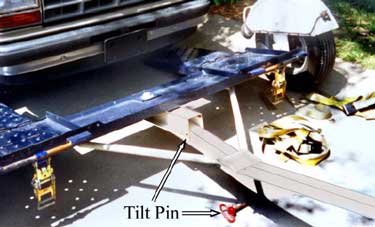

The trucks were parked in front of the man’s home on a residential street which was fairly level (see Photo 1). The sequence of events is not clear, but at the time of the incident, the victim was working under the truck-in-tow. The truck had its transmission in the park position, and the foot-operated parking brake was engaged. The straps securing the front wheels to the dolly were taken off the wheels (see Photos 2, 3). The tilt locking pin which locks down the carrying pan of the dolly was not in place (see Photo 3). It is not clear whether the victim had already re-positioned the truck by driving it off and back onto the dolly. The other man arrived from the house with his tools, and the victim quit working with the front wheels and crawled underneath the passenger side of the truck-in-tow with tools in hand to disconnect the drive shaft from the differential. Besides engaging the parking brake and setting the transmission in park, the victim did not use other means to secure the truck from rolling before crawling underneath. He was lying on his right side facing the rear of the vehicle.

|

|

Photo 3 – Front view of tow dolly showing tilt pin removed and ramp tilted downward. (Photo enhanced for clarity)

|

When the victim removed the last bolt connecting the drive shaft to the differential, the truck immediately began to roll. Because the tilt locking pin had been removed, the ramp for the dolly tilted downward, and the truck rolled down the ramp and crushed the victim against the pavement, causing asphyxiation. The other man tried to push the truck back up the ramp, but was unable to do so. He then ran to get a jack from his garage while his wife called 911. He was unable to raise the truck off the man with his jack, and had to wait for emergency rescue, which arrived in five minutes. Using the Jaws of Life and cribbing, fire crews pulled the man from under the truck, but he was declared dead when seen by medical personnel. The disconnected back end of the drive shaft was on the ground and did not contribute to the man’s injuries (see Photo 4).

This type of two-wheeled dolly is used frequently for transporting passenger cars behind RVs and other vehicles. The manufacturer of this model states in the operator’s manual that the dolly is not designed for commercial applications, and that the warranty would be void in such case. The dolly is designed so that when the front wheels of the vehicle-in-tow are driven up the ramp, the ramp and the carrying pan will tilt forward to a horizontal position. A heavy tilt locking pin is then inserted through the tongue to lock the carrying pan in position. Then the front wheels are secured to the dolly using heavy-duty straps. At the time of the injury, the tilt locking pin was removed and the dolly’s carrying pan and ramps were free to tilt back. The wheel straps were removed, and there were no chocks, wheel stops or other means in place to keep the truck from rolling. The dolly itself did not appear to be defective or to malfunction, and the terrain appeared level. The towing truck in front was a newer half-ton truck with the hitch ball on its bumper. It did not have a frame-mounted trailer hitch where the ball is usually lower. The truck’s higher bumper hitch ball position may have set the dolly slightly upward, which could have allowed the truck-in-tow to roll backwards more easily.

It is unclear whether the victim had already repositioned the truck or was preparing to do so. In either case, he had removed the wheel straps and the tilt locking pin. He proceeded to remove the drive shaft before securing the truck to the dolly. It is unclear whether he was aware of the proper safe loading procedures, or whether he may have been distracted in some way. In this situation, the wheel straps, tilt locking pin, parking brake, and transmission park position, all failed to keep the vehicle from rolling off the dolly.

The truck-in-tow had a typical foot-actuated parking brake. The pedal was connected to a single cable, which splits into two going to both rear drum brakes. An officer at the scene examined the parking brake and found it to be defective. The pedal pushed down only halfway, as compared to normal parking brakes, and there was no audible ratchet sound when the pedal moved. The pedal did return when released, but the brake was apparently not working sufficiently to stop the truck from rolling down the ramp. Since this mechanical brake was defective, the truck was held in position on the ramps only because the transmission was in the park position, and the drive shaft alone was holding the truck on the ramp. With the drive shaft removed, there was nothing to stop the truck from rolling.

This company was cited by OSHA for not following the correct procedures in the owner’s manual to tie-down the vehicle to the tow dolly. The company also failed to provide a means of securing or blocking the vehicle to prevent any rolling off the dolly.

|

|

Photo 4 – View from driver’s side of the vehicle-in-tow showing the drive shaft disconnected from the differential.

|

Cause of Death

The cause of death, as taken from the medical examiner’s report was, “mechanical asphyxiation due to vehicle on decedent’s chest”. An autopsy was conducted. The victim was not injured by the drive shaft seen in Photo 4.

Recommendations/Discussion

Recommendation #1 Employers must provide proper safety training for employees who transport company vehicles, including how to safely remove drive shafts on vehicles-in-tow.

Discussion: The victim in this incident was disconnecting the drive shaft in preparation for towing a truck. He had performed this task many times in the past. It appears that he had removed the wheel straps so that he could drive and reposition the truck on the dolly. The straps and the tilt locking pin were not in place when he proceeded to work under the vehicle, leaving the vehicle unsupported. Employee training should include specific instructions about safely removing the drive shaft, and how to support the vehicle properly and avoid the circumstances encountered in this incident.

The victim had the parking brake and the transmission park engaged. However, parking brakes on older vehicles are often unreliable. The park position of an automatic transmission will hold the vehicle in place in normal parking situations. However, it requires that the power train is intact. Disconnecting the drive shaft, raising a driving wheel from the ground, or other reasons can make the transmission park ineffective. In this case, removal of the drive shaft removed the only braking for the vehicle, and allowed it to roll down the dolly ramp. It is not clear whether the victim had already finished his task re-positioning the truck, preparing to do it, or leaving the truck as is. In any case, the front wheels should have been secured to the dolly by the straps, and the tilt locking pin should have been inserted before he proceeded to disconnect the drive shaft

Recommendation #2 Employers should provide proper tools and wheel chocks with vehicles that are used to tow other vehicles.

Discussion: Company trucks that service a fleet of vehicles or transport other vehicles should be outfitted with all necessary tools and equipment to safely complete the job. The victim in this case had to deviate from his travel plans and rely on borrowed tools to disconnect the drive shaft, which is a routine part of towing a rear wheel drive vehicle. This interruption may have distracted him, contributing to the fatal event. Additionally, the provision and use of wheel chocks as a standard backup safety measure would have prevented this fatality. Wheel chocks are an inexpensive and reliable means to keep vehicles in place in many situations, including this incident.

Recommendation #3 Manufacturers of tow dollies should provide reliable locking mechanisms and clear instructions how to safely load, unload, and transport vehicles.

Discussion: The tow dolly in this case did not appear to malfunction, and the operator’s manual did have instructions which would have prevented this injury. However, some improvements could be considered. It might be possible to develop a tilt-locking mechanism, which would be automatically locked at all times, except when specifically actuated for tilting the wheel pan and ramps for loading and unloading. The pin used in this case could provide additional protection. Having two mechanisms for securing the tilt might be beneficial also to avoid pin failures and potential unintentional rolling events. The operator’s manuals should clearly warn about securing the vehicle with wheel straps and tilt locking mechanisms before working under the vehicle, or disconnecting the drive shaft While the parking brake may help, it is not reliable. The transmission park position does not provide any protection when the drive shaft is disconnected. Another contributing factor in this incident was the high ball position, which tilted the dolly slightly downward. The operator’s manual in this case does address the height if the ball, but it might be important to stress the issue and set clear requirements for the height of the ball.

Iowa FACE Program

FACE is an occupational fatality investigation and surveillance program of the National Institute for Occupational Safety and Health (NIOSH). In the state of Iowa, The University of Iowa, in conjunction with the Iowa Department of Public Health carries out the FACE program. The NIOSH head office in Morgantown, West Virginia, carries out an intramural FACE program and funds state based programs in Alaska, California, Iowa, Kentucky, Massachusetts, Michigan, Minnesota, Nebraska, New Jersey, New York, Oklahoma, Oregon, Washington, West Virginia, and Wisconsin.

The purpose of FACE is to identify all occupational fatalities in the participating states, conduct indepth investigations on specific types of fatalities, and make recommendations regarding prevention. NIOSH collects this information nationally and publishes reports and Alerts, which are disseminated widely to the involved industries. NIOSH FACE publications are available from the NIOSH Distribution Center (1-800-35NIOSH).

Iowa FACE publishes case reports, one page Warnings, and articles in trade journals. Most of this information is posted on our web site listed below. Copies of the reports and Warnings are available by contacting our offices in Iowa City, IA.

The Iowa FACE team consists of the following from the University of Iowa: Craig Zwerling, MD, PhD, MPH, Principal Investigator; Wayne Johnson, MD, Chief Investigator; John Lundell, MA, Coordinator; Risto Rautiainen, PhD, Co-Investigator, Martin L. Jones, PhD, CIH, CSP, Co-Investigator, and John Kraemer, PA. From the Office of The State Medical Examiner.

To contact Iowa State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.