Farmer Killed When Tricycle Tractor With Front-End Loader Overturns

SUMMARY

|

|

Photo 1 – Shot of the rear of the overturned tractor, facing north.

|

During the fall of 2002 a 38-year old Iowa farmer was killed when his tractor overturned in a cattle feedlot. This narrow-front 1966 model tractor was equipped with a front end loader, and had been in the family for three decades. The man was moving a small pile of dirt from the farmyard to the feedlot to repair soil erosion next to a building and a feed trough. The area was slightly sloped to the Northeast.

The farmer had a full load of dirt in the raised front-end loader bucket. He had just entered the feedlot area, and turned left towards the concrete feed troughs, positioning the tractor to unload the bucket. The overturn was not witnessed and the conditions leading to the overturn are not fully clear. The findings suggest that a combination of several factors may have resulted in the overturn. These factors include narrow front of the tractor, raised front end loader with a heavy load, moving slightly downhill, slightly uneven ground, turning left, and slowing down while turning. These factors may have added to the momentum at this critical point sufficiently overturning the tractor to the right. The tractor rolled 180 degrees, coming to rest upside down (see Photo 1). The farmer was crushed underneath and killed instantly. This tractor had no Rollover Protective Structure (ROPS), which would likely have saved this man’s life by preventing a complete rollover. However, for this fairly common tractor model, there are no commercially available ROPS on the market.

RECOMMENDATIONS based on our investigation are as follows:

- All tractors should be equipped with Roll Over Protective Structures (ROPS).

- ROPS should be designed for all common tractor makes and models.

- Narrow-front (tricycle type) tractors should not be equipped with front-end loaders.

INTRODUCTION

In the fall of 2002, a 38-year-old Iowa farmer was killed when his tractor rolled over on top of him. The Iowa FACE program was notified of the incident from a newspaper article, and began an investigation, gathering information from the county sheriff and family members. That winter, two Iowa FACE investigators visited the farm, photographed the area, and reviewed photographs and information with the Sheriff.

The victim lived on an 80 acre farm and raised cattle and hay. He was a lifelong farmer and had extensive experience with machinery, having operated this narrow-front tractor since he was 9 years old. He and his wife had lived at this location for the past 14 years and farmed part-time. The victim was working alone on the day of his death, and was found by his wife.

There was no safety program for this small farm. The victim and his brother had attended a tractor safety course several years prior. The victim and his wife had discussed tractor safety, and the man knew of rollover hazards, and had discussed ways to avoid injury if the tractor ever began to roll. The man took very good care of his machinery. The involved tractor was one of three tractors on the farm, and the only tractor with a front-end loader. The victim had just called to order a front-end loader for one of their other tractors, which had a wide front end.

INVESTIGATION

The farmer was using his narrow-front 1966 tractor and front-end loader to move a pile of dirt from the flat farm yard into his cattle feedlot. The dirt pile was created during construction of a basketball hoop near the driveway to the farm. The dirt was being moved to cover areas of erosion in the feedlot near a machine shed and along a cattle feeding trough. This task had been done before using the same equipment.

The 1966 model tractor had been in the family for the past 30 years, and was used for various chores on the farm. It had sentimental value to the family, as the victim learned to drive on this tractor when he was 9 years old. A front-end loader was added 15 years ago, as were new and taller tires to the front end. The tractor had just received hydraulic maintenance, and was in good operating condition.

|

|

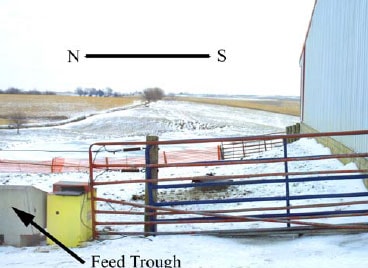

Photo 2 – Entry gate of feedlot facing East.

|

The feedlot was near the farmyard on the north side of the machine shed. It had a long concrete feed trough on its western edge (see Photos 2, 3). Several bucket loads of dirt had already been dumped and spread near the machine shed, and the farmer was dumping and leveling the remainder of the dirt next to the feed trough. Entry into the feedlot was from a gate between the south end of the feed trough and the machine shed (see Photo 2). The farmer had entered the feedlot and turned left towards the feed trough. He was adjacent and parallel to the feed trough at the time of the overturn.

The terrain in the feedlot was soft dirt, and it sloped slightly to the Northeast (see Photo 2). The slope was only a few degrees, and would typically not raise concern about tractor overturn. A relative stated the tractor had routinely been operated in much steeper terrain, and he cannot imagine how the tractor could overturn at this location. He mentioned that if the tractor front end goes over a bump, the hydraulics might “pop or the loader may bang down hard”, but he could not see how this could contribute to this rollover.

|

|

Photo 3 – View from the ground looking up the old grain bin ladder.

|

The farmer entered the feedlot with a full load of dirt in the raised bucket. The bucket was slightly higher than the tractor hood after the overturn, and was likely in this raised position also before the overturn. Apparently when he finished his left turn, with the brakes applied, the momentum and speed of the tractor with the raised front bucket were sufficient to roll the tractor to the right, and it continued to roll completely upside down. The farmer was thrown to his left, and was pinned to the ground by a light on the left rear fender.

The right rear wheel on the tractor was unclamped after the rollover (see Photo 1). There was no damage evident on the rim, and this was not thought to be a factor in this accident. The hydraulic lever to dump the bucket was pushed forward. It is possible that the victim had just activated the lever when the overturn occurred. However, the load of dirt appeared to be still in the bucket during the overturn, and most of the dirt landed under that overturned bucket.

CAUSE OF DEATH

The cause of death from the Medical Examiner’s report was, “head / neck trauma due to tractor accident”. An autopsy was performed.

RECOMMENDATIONS / DISCUSSION

Recommendation #1 All tractors should be equipped with Roll Over Protective Structures

Discussion: ROPS are known to be very effective in reducing deaths from tractor overturns. Tractors manufactured after 1986 have ROPS, but about half of tractors in the United States do not yet have ROPS. Studies have suggested that risk factors for overturns include narrow front (tricycle design), using a front-end loader, and using the tractor for mowing on sloping ground. The tractor in this case was an old tricycle-type tractor equipped with a front-end loader. It is important that especially high risk tractors that are used frequently for loading, mowing, or road transport are equipped with ROPS. In this case, ROPS was not commercially available, but for the majority of functioning older tractors, ROPS are available at fairly reasonable cost.

Recommendation #2 ROPS should be designed for all common tractor makes and models.

Discussion: This 1960’s tractor model (Farmall 560) is quite common, with an estimated 35,000< units still in use in the US (Myers and Snyder, 1995). There are no commercially available ROPS for this tractor. It would be important that a ROPS design is prepared for this tractor model, and approved ROPS made commercially available. Most non-ROPS tractors in use do have an available ROPS, but some models, such as this, have been difficult to retrofit due to the characteristics of the rear axle or other reasons. For some of the remaining tractors without ROPS design, the ROPS may need to be four-post style, which is more costly to manufacture and install. However, it would be important to make ASAE approved (ASAE, 2001) ROPS available for the most common remaining non-ROPS tractors to avoid future overturn fatalities.

Recommendation #3 Narrow-front (tricycle type) tractors should not be equipped with front-end loaders.

Discussion: The combination of having a front-end loader on a tricycle type tractor has been found to be extremely hazardous in many previous FACE investigations. This type of tractor was common in the past, and many of these tractors are still in daily use. Tricycle-type tractors are more prone to overturns than wide-front tractors, and should not be used with front-end loaders or other attachments, which can significantly change the machine’s center of gravity. Raising or supporting a heavy load with the front-end loader bucket shifts weight from the back wheels to the narrow front wheels and decreases the tractor’s stability. Sideways forces from pulling, making sharp turns, or moving on uneven ground can easily cause an overturn.

REFERENCES

Myers JR, Snyder KA. Roll-over Protective Structure use and the cost of retrofitting tractors in the United States, 1993. Journal of Agricultural Safety and Health. 1(3):185-197, 1995.

American Society of Agricultural Engineers (ASAE). Roll-Over Protective Structures (ROPS) for Wheeled Agricultural Tractors. Standard S.383.1, January 2001.

Fatality Assessment and Control Evaluation

FACE

FACE is an occupational fatality investigation and surveillance program of the National Institute for Occupational Safety and Health (NIOSH). In the state of Iowa, The University of Iowa, in conjunction with the Iowa Department of Public Health carries out the FACE program. The NIOSH head office in Morgantown, West Virginia, carries out an intramural FACE program and funds state based programs in Alaska, California, Iowa, Kentucky, Massachusetts, Michigan, Minnesota, Nebraska, New Jersey, New York, Oklahoma, Oregon, Washington, West Virginia, and Wisconsin.

The purpose of FACE is to identify all occupational fatalities in the participating states, conduct in depth investigations on specific types of fatalities, and make recommendations regarding prevention. NIOSH collects this information nationally and publishes reports and Alerts, which are disseminated widely to the involved industries. NIOSH FACE publications are available from the NIOSH Distribution Center (1-800-35NIOSH).

Iowa FACE publishes case reports, one page Warnings, and articles in trade journals. Most of this information is posted on our website listed below. Copies of the reports and Warnings are available by contacting our offices in Iowa City, IA.

The Iowa FACE team consists of the following from the University of Iowa: Craig Zwerling, MD, PhD, MPH, Principal Investigator; Wayne Johnson, MD, Chief Investigator; John Lundell, MA, Coordinator; Risto Rautiainen, PhD, Co-Investigator, Martin L. Jones, PhD, CIH, CSP, Co- Investigator, and John Kraemer, PA. From the Office of The State Medical Examiner.

To contact Iowa State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.