Young Farmer Crushed Under Rolling Silage Wagon

Case No.: 02IA050 Report Date: March 8, 2004

SUMMARY

|

|

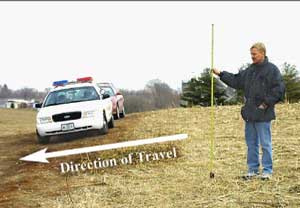

Photo 1 – Front view of silage wagon.

|

During the fall of 2002, a 22-year-old farmer was killed while cutting corn silage on his farm. He was working with his brother, chopping silage for their dairy operation. The brother was driving a tractor, pulling the corn chopper and silage wagon. After the wagon was full, they stopped at the edge of the field and the victim disconnected the wagon, planning to hook up an empty wagon nearby. The wagon was on a slight slope and it slowly began to creep forward after disconnecting. The victim first jumped on the tongue, expecting it to dig into the ground and stop the wagon, but it continued to move. He then picked up the tongue, trying to turn the wagon more uphill to stop it from rolling. At this point, he was walking / running backwards in tall grass. His brother yelled to him to get out of the way, but he apparently slipped and his pant leg was caught by the wagon’s running gear. The silage wagon continued to roll several hundred feet downhill, dragging the victim along. The brother used a cell phone to call 911, and another relative arrived and began cardiopulmonary resuscitation (CPR). The victim had received multiple blunt force injuries, and was declared dead when he arrived at the hospital.

RECOMMENDATIONS based on our investigation are as follows:

- Silage wagon manufacturers should provide a mechanism to secure the wagon while parked on sloping ground.

- Silage wagon operators should use chocks or other means to secure wagons on sloping ground.

- Farmers should not attempt to stop a moving wagon by stepping on the wagon tongue or turning it.

- Silage wagons should be parked on level ground when possible.

INTRODUCTION

During the fall of 2002, a 22-year-old Iowa farmer was killed when a silage wagon ran over him. The Iowa FACE program was alerted to this incident from a newspaper article, and began an investigation. Initial information was gathered from the County Sheriff’s office, and a site visit was scheduled for later in the fall. Two investigators from the Iowa FACE program met with an investigator from the Sheriff’s office, and visited the location where the runover occurred. They reviewed Sheriff’s photos and took photographs of the wagon where it was stored on a relative’s farm.

The young farmer worked with his brother on a 180-acre dairy farm, and milked 58 cows. The farm had 20 acres in corn, which was being chopped for silage on the day of the incident. This was a family farm, and the two brothers had worked side-by-side for many years, often assisted by their father.

This family farm did not have a safety program or written procedures or policies. There were no outside employees. The men were very familiar with all equipment and operations on their farm. The victim’s brother was present at the time of the accident, and was an eyewitness. He immediately ran to the farm house and told relatives to call 911, then ran to aid his brother. Another relative returned with him from the house and began to administer CPR. Rescue personnel arrived in a few minutes, however, the young farmer was declared dead on arrival at the hospital due to severe internal injuries.

INVESTIGATION

The incident took place during harvest on a dairy farm in eastern Iowa. The two brothers were chopping a field of corn for silage to feed their dairy cows. This was a task they had performed many times before in the same fields with the same equipment. A tractor was pulling the chopper and the silage wagon. The silage box was 14 foot (4.3 m) long, 8 foot (2.4 m) wide, and 6 foot (1.8 m) tall, and sat on a running gear made by a different manufacturer. The running gear had dual rear axels, and the wagon had a capacity of ~10 tons. There were no brakes on the wagon, nor were chocks used out in the field.

The corn field was on a hill and was sloping towards the edges (see Photo 3). The victim’s brother was driving the tractor, and had stopped at the edge of the field to change silage wagons, as the first wagon was completely full. The wagons were often left along this edge of the field to be later transported to the farmstead for unloading.

The victim’s brother stopped the tractor, while the victim went to disconnect the full silage wagon from the chopper. The wagon tongue (see Photo 2) had a telescoping feature to aid in attaching it to the tractor or chopper hitch. The victim pulled out the hitch pin, and the brother drove forward. After disconnecting, the full wagon unexpectedly began to creep forwards. The victim jumped on the tongue, attempting to stop it. However, the wagon continued to move forward. He then attempted to pick up the tongue and turn the front wheels uphill, but the tongue slipped out of his hands and the wagon kept rolling.

The brother on the tractor was watching this happen, and yelled to his brother to get out of the way. The victim was walking/running backwards for a moment, then fell in tall grass and his leg became entangled over the tie-rod of the wagon, near the right front wheel. The silage wagon continued to roll downhill for an additional 500 feet (150 m), dragging him under the wagon into another cornfield. From the markings in the ground on the hillside, it was evident the tongue had scraped the dirt along the way down the hill, but not enough to stop the wagon until it came to rest at the bottom of the hill.

The incident occurred on hilly ground, as seen in Photograph 3, with corn rows in the direction of the arrow. The edge of the field was used as a transport path to this field and other adjacent fields. Most farmland in this area is hilly, and the farmers were used to operating machinery in the sloping fields at this farm. Silage wagons were often left in similar positions in this field before without incident, but in this case, the wagon started to roll. Possibly the wagon was pulled further into the path area, which had a steeper slope. The ground was dry and hard, which may have contributed to the wagon to roll. The dry ground also prevented the tongue from digging into the ground, and stopping the wagon.

|

|

|

Photo 3 – View of edge of cornfield, showing degree of slope.

|

CAUSE OF DEATH

The cause of death from the Medical Examiner’s report was “blunt force injuries of head and chest”.

RECOMMENDATIONS / DISCUSSION

Recommendation #1: Silage wagon manufacturers should provide a mechanism to secure the wagon while parked on sloping ground.

Discussion: Silage wagons are often disconnected on sloping terrain where they may start to roll, causing injury and/or material damage. Manufacturers should recognize this hazard and provide a mechanism, such as chocks or parking brakes, to secure the wagon. Providing chocks and a proper easily accessible storage location for them on each wagon would not add significant cost to the wagon, but would provide one effective solution to improve safety. Another solution could be a parking brake that can be activated at the time of disconnecting the wagon. This solution is likely more costly, but could be faster, easier to use, and potentially effective.

Recommendation #2: Silage wagon operators should use chocks or other means to secure wagons on sloping ground.

Discussion: Rolling of silage and grain wagons is a known hazard when operating on sloping ground. Farmers and operators of wagons should anticipate this, and have chocks or other means readily available to stop potential rolling. Most wagons are not equipped with chocks by the manufacturer, but they can be easily added. As dozens of wagon loads may be transported during harvest, any safety measures must be simple and easy to use. Using chocks may take some extra time, but it provides a simple and safe method to secure the wagon and avoid injury.

Recommendation #3: Farmers should not attempt to stop a moving wagon by stepping on the wagon tongue or turning it.

Discussion: After disconnecting a wagon, farmers may habitually step on the implement tongue, or pick up the tongue and steer the wagon uphill to stop it from rolling on sloping ground. These methods may be successful in some situations, but in this case, the tongue did not dig into the dry hard ground, and the farmer slipped and fell in tall grass while attempting to steer the wagon. As the wagon increases in weight, it may be more difficult to stop. Any attempts to stop runaway equipment are extremely hazardous and should not be attempted.

Recommendation #4: Silage wagons should be parked on level ground when possible.

Discussion: Silage wagon operators should pay great attention to ground conditions when preparing to disconnect the wagon. Often there may be safe level locations in the field that can be used for disconnecting and parking a loaded wagon safely. This may require stopping at a safe location before the wagon is completely filled, or taking extra time for driving to a safe level location. While this may slightly reduce productivity, it may be necessary to avoid serious injuries and/or serious damage to the wagon and other property.

Fatality Assessment and Control Evaluation

FACE

FACE is an occupational fatality investigation and surveillance program of the National Institute for Occupational Safety and Health (NIOSH). In the state of Iowa, The University of Iowa, in conjunction with the Iowa Department of Public Health carries out the FACE program. The NIOSH head office in Morgantown, West Virginia, carries out an intramural FACE program and funds statebased programs in Alaska, California, Iowa, Kentucky, Massachusetts, Minnesota, Nebraska, New Jersey, New York, Ohio, Oklahoma, Texas, Washington, West Virginia, and Wisconsin.

The purpose of FACE is to identify all occupational fatalities in the participating states, conduct indepth investigations on specific types of fatalities, and make recommendations regarding prevention. NIOSH collects this information nationally and publishes reports and Alerts, which are disseminated widely to the involved industries. NIOSH FACE publications are available from the NIOSH Distribution Center (1-800-35NIOSH).

Iowa FACE publishes case reports, one page Warnings, and articles in trade journals. Most of this information is posted on our web site listed below. Copies of the reports and Warnings are available by contacting our offices in Iowa City, IA.

The Iowa FACE team consists of the following from the University of Iowa: Craig Zwerling, MD, PhD, MPH, Principal Investigator; Wayne Johnson, MD, Chief Investigator; John Lundell, MA, Coordinator; Risto Rautiainen, PhD, Co-Investigator, Martin L. Jones, PhD, CIH, CSP, Co- Investigator, and John Kraemer, PA. From the Office of The State Medical Examiner.

To contact Iowa State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.