Farmer Fatally Injured by Rotary Mower When Tractor Seat Falls Off

SUMMARY

|

| Photo 1 — Side view of identical tractor model. |

A 56-year-old grain farmer was killed when the seat of his tractor fell off while driving through a washout area in a cornfield. The man was driving a 1950’s model two-cylinder tricycle-type tractor, pulling a rear-mounted rotary mower. His other tractor was in the shop, so he was using this older tractor. He had recently rented the field and was working it the first time, mowing corn stalks and preparing the field for spring planting. While mowing, he drove into what appeared to be a washout from a tile standpipe. The force of the jolt knocked the seat and the farmer off the tractor. The man fell into the washout area, and the mower ran over him, causing fatal head injuries. He was found dead the next day. This tractor model had a sliding seat attachment for adjusting the seat position with a spring-loaded pin locking the seat in place. This pin was damaged, and was not able to keep the seat firmly in place. There are metal tabs at the end of the tracks keeping the seat from sliding off the tracks. Apparently these stops were not adequate, and the seat slid back, and separated from its base.

RECOMMENDATIONS based on our investigation are as follows:

#1 Owners/operators of tractors should ensure that the tractor seat is in good condition and firmly attached to the base.

#2 Tractors should be equipped with ROPS and seatbelt, which should be used when mowing.

#3 Equipment manufacturers should design the seat support structure to withstand use in demanding conditions for the lifetime of the tractor.

#4 Farmers should be alert for washouts and other hazardous conditions in fields and repair them, or clearly mark them, to avoid injury.

INTRODUCTION

A 56-year-old Iowa farmer was found dead, lying under a rotary mower in a cornfield in March 2000. The tractor involved in this incident had been sold to an out-of-state buyer, and we were unable to examine the tractor. A relative of the victim knew of other tractors in his area that were identical to the one involved in the incident. We met with him and examined two similar tractors and took photographs.

The victim had a small grain farm operation of 190 acres, rotating corn and soybeans. He owned 90 acres on his farm and rented the remainder from neighbors. He did not have livestock. This was a hobby farm for him, which he bought two years ago. His permanent address was in another county, where he worked in agricultural business. He grew up on a farm, and had worked with farm machinery his entire life. He was accustomed to working alone, and was helped occasionally by his college-age son. This small farm did not have an official safety program or written policies.

INVESTIGATION

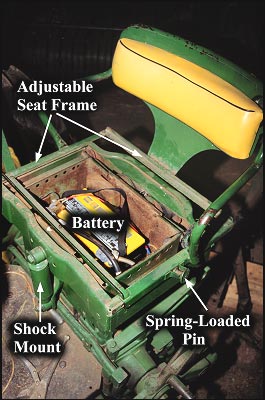

|

| Photo 2 — Top view of seat showing seat frame, battery housing, and adjustable pin. (cushion removed) |

The victim was using his 1950’s model tricycle-type tractor to mow corn stalks and foxtail grass in a 33 hectare (80-acre) terraced field, which had been harvested the fall before. The farmer had recently rented this field, and this was the first time he had driven over it, preparing it for spring planting.

The tractor had a pull-type rotary mower attached to the drawbar. The mower had a 1.5-meter (5-ft) capacity, wide enough for two rows of corn. The farmer had two other larger and newer tractors at his farm. One was in the shop getting repaired, and the farmer chose to use this older for cutting the cornstalks.

While working in a flat section of the field, the narrow-front tires of his tractor fell into a 0.9-1.2 meter (3-4 foot) deep tile washout, or blowout, and the large jolt dislodged the tractor seat off its tracks. The tractor continued forward, and the seat, along with the farmer, fell off the tractor and landed in the washout depression. The farmer was run over by the mower and received fatal head injuries. The man was not found until the next day.

The battery housing forms the base of the seat on this tractor (see Photo 2). A shock-absorbing main seat frame is built around the battery housing. The seat cushion, backrest, and armrests are attached to the top part of the frame, which is adjustable and slides on tracks at the edges of the main frame. A spring-loaded pin on the left side of the seat locks the seat in place (see Photo 3).

In the photo, the pin is operational, but according to the victim’s relatives, it was damaged, and the tractor was in overall poor condition. We were not able to observe the tractor, so the extent of the damage is not clear, but considering the age of the tractor, many forms of wear and tear could damage the pin.

The adjustable top part of the seat frame moves forward and backward on the tracks/grooves. Bent metal tabs at the end of the tracks are designed to keep the seat in the adjustable range. The back and armrests are welded directly onto the sliding top part of the frame (see Photo 4). Over time this seat attachment may become loose, especially if the spring-loaded pin is not keeping the seat in place. The tabs may wear, and the top frame may bend or wear and be more prone for sliding out of the tracks.

The tile washout or blowout had occurred in the field and the farmer had no knowledge of it. A field tile was draining the terraced section of the field above it, and was buried 0.9-1.2 meters (3-4 ft) underground. This tile apparently had a hole in it, and the resulting surge of water through the hole washed away the soil above it, leaving a conical depression in the field. There was no obvious ditch created from flowing water, but just a sinkhole on top of the leaking tile. This sinkhole created a dangerous condition, as it was not easily recognizable in the middle of the field, and grown up grass could obscure the hole. It is unlikely the victim had any warning before his tractor wheels fell into the sinkhole.

|

|

| Photo 3 — Close-up of spring-loaded pin on left side. | Photo 4 — View of left side of seat, showing sliding track and armrests welded to the seat edge. |

CAUSE OF DEATH

The official cause of death taken from the death certificate was, “severe head trauma due to multiple facial lacerations”.

RECOMMENDATIONS / DISCUSSION

Recommendation #1 Owners/operators of tractors should ensure that the tractor seat is in good condition and firmly attached to the base.

Discussion: Machines should be kept in good repair, including the seat. The seat on this tractor was in poor condition. The attachment was worn and when driving unexpectedly into a sinkhole in the field the jolt separated the seat from the frame and threw the operator off the tractor. This tractor was used because the regular tractor was in the shop, and this older tractor was adequate for operating the small mower. Older tractors like this are often used for mowing.

The condition of the seat is very important when mowing ditches and sloping grounds. Washouts, animal holes, rocks, stumps and other objects can cause unexpected jolts. The operator can lose control of the tractor if the seat attachment fails.

Recommendation #2 Tractors should be equipped with ROPS and seatbelt, which should be used when mowing.

Discussion: This tractor had no Rollover Protective Structure (ROPS) and no seatbelt. Both ROPS and a seatbelt are necessary for safe operation of a tractor when mowing. The primary purpose of ROPS and seatbelts is to protect the operator in tractor overturns, which are common when mowing. In this case, using a seatbelt could have helped keep the operator from falling off the tractor. However, seatbelts are recommended only on tractors equipped with ROPS. For this particular tractor model, ROPS is not readily available. Using non-ROPS tractors for hazardous tasks, such as mowing and loading, should be avoided if possible.

Recommendation #3 Equipment manufacturers should design the seat support structure to withstand use in demanding conditions for the lifetime of the tractor.

Discussion: The seat frame in this tractor was separated from its base during a strong jolt. It appears the seat slid back and the tabs at the end of the tracks were not able to stop it. It’s also possible that the adjustable top part of the frame was bent and loose enough that it pulled the seat up and out of the tracks during the jolt. In either case, the seat adjustment mechanism was not secure enough to hold the seat in place. The challenges in manufacturing a tractor seat are significant and include adjustability for various size operators, shock absorption, vibration damping, weather and corrosion resistance, durability, and comfort. Some recent seat models allow the seat to rotate to the right to reduce bending of the back when observing implements behind the tractor. Furthermore, some seats tilt to remain vertical when driving on sloping ground. Regardless of the features of the seat, the construction of the seat frame and its support structure should be able to withstand use in demanding conditions.

Recommendation #4 Farmers should be alert for washouts and other hazardous conditions in fields and repair them or clearly mark them to avoid injury.

Discussion: Driving unexpectedly into a washout in the field contributed to this fatal injury. It is not clear when this washout had developed or whether the farmer or the owner of the field had noticed it before. It is possible that it was present during harvest the previous fall. Farmers should observe their fields during regular planting, tillage, pesticide application, and harvest times, and mark and/or correct these situations that present a danger when operating field machinery.

Fatality Assessment and Control Evaluation

FACE

FACE is an occupational fatality investigation and surveillance program of the National Institute for Occupational Safety and Health (NIOSH). In the state of Iowa, The University of Iowa, in conjunction with the Iowa Department of Public Health carries out the FACE program. The NIOSH head office in Morgantown, West Virginia, carries out an intramural FACE program and funds state based programs in Alaska, California, Iowa, Kentucky, Maryland, Massachusetts, Minnesota, Missouri, Nebraska, New Jersey, Ohio, Oklahoma, Texas, Wisconsin, Washington, and Wyoming.

The purpose of FACE is to identify all occupational fatalities in the participating states, conduct in-depth investigations on specific types of fatalities, and make recommendations regarding prevention. NIOSH collects this information nationally and publishes reports and Alerts, which are disseminated widely to the involved industries. NIOSH FACE publications are available from the NIOSH Distribution Center (1-800-35NIOSH).

Iowa FACE publishes case reports, one page Warnings, and articles in trade journals. Most of this information is posted on our web site listed below. Copies of the reports and Warnings are available by contacting our offices in Iowa City, IA.

The Iowa FACE team consists of the following: Craig Zwerling, MD, PhD, MPH, Principal Investigator; Wayne Johnson, MD, Chief Investigator; John Lundell, MA, Coordinator; Lois Etre, PhD, Co-Investigator; Risto Rautiainen, MS, Co-Investigator.

To contact Iowa State FACE program personnel regarding State-based FACE reports, please use information listed on the Contact Sheet on the NIOSH FACE web site Please contact In-house FACE program personnel regarding In-house FACE reports and to gain assistance when State-FACE program personnel cannot be reached.

Back to NIOSH FACE Web