Public-Utility Foreman Dies After Being Struck Against the Protective Cab of a Tractor--Virginia

FACE 9609

SUMMARY

A 62-year-old male public-utility foreman (the victim) died after he was pulled against the metal protective-cab enclosure of a tractor. Prior to the incident, the victim had been cutting brush with a chain saw on the bank of a settling pond; a rope was tied around his waist, and held by a groundsman at the top of the bank, to keep him from falling into the pond. At the time of the incident, the groundsman had laid the end of the rope down on top of the bank and walked down the bank to assist the victim, who was having a problem with the chain saw. As they worked on the chain saw, an equipment operator was driving a tractor with a brush-hog attachment, on top of the pond’s bank. The brush-hog was cutting weeds and grass, when it was pulled over the end of the rope, and the rope became entangled in the machine’s drive shaft and blades. The rope became taut and the victim was violently jerked up the pond’s bank and through the air, into the metal protective-cab enclosure of the tractor. The victim contacted the enclosure head-first, then came to rest on the back tire of the tractor. After witnessing the incident, the groundsman and equipment operator ran to aid the victim and summon help. The victim was moved from the tractor’s tire and the equipment operator alerted another foreman in the area, who called 911 for assistance. Emergency medical service personnel arrived in 3 minutes and evaluated the victim, who was pronounced dead at the scene. NIOSH investigators concluded that, in order to prevent future similar occurrences, employers should:

- review and revise, where applicable, safe job procedures that address employees working in proximity to operating equipment

- develop safe job procedures to include, but not be limited to, procedures that direct equipment operators to stop equipment when spotters are out of sight, and to work on equipment in a designated area that is free of hazards

- provide and ensure that employees wear full body harnesses when tied off

- conduct scheduled and unscheduled safety inspections to ensure that safety procedures are being followed.

INTRODUCTION

On December 21, 1995, a 62-year-old male public utility foreman (the victim) died after he was pulled against a metal protective-cab on a tractor. On December 29, 1995, officials of the Virginia Occupational Safety and Health Administration (VOSHA), notified the Division of Safety Research (DSR) of the death, and requested technical assistance. On February 13, 1996, a DSR safety specialist traveled to the incident site to conduct an investigation. The incident was reviewed with two representatives from the company and with the OSHA compliance officer assigned to the case. Photographs of the equipment involved in the incident were taken, and a video tape, which was taken after the incident occurred, was reviewed, along with the coroner’s report.

The company involved in this incident has been in business for 89 years and provides right-of-way and utility-line clearance services. The company employs 1,500 workers in 5 districts throughout the mid-Atlantic states. The company has a written safety policy, designated safety director, and a written safety program. Training is accomplished on-the-job, and with the use of manuals and videos. Tailgate safety sessions are held weekly by the foreman and quarterly safety meetings are held in each district. Employees are given safe work practices handbooks at the time they are hired. The victim had worked for the employer for 6 years. This was the second fatality experienced in the company’s history.

INVESTIGATION

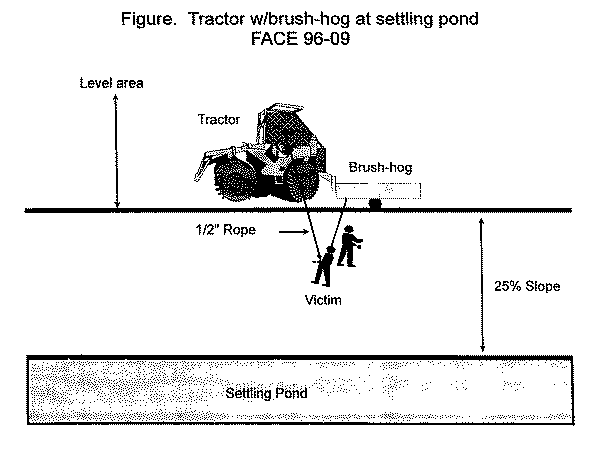

The company was in the second year of a contract to clear brush and weeds/grass from around a settling pond at a foundry complex. The pond was rectangular in shape and about 2 acres in size. The land surrounding the pond was level, with a sloping bank of about 25% grade, down to the water’s edge. The day of the incident was the crew’s second day at the pond. The crews, one consisting of a foreman and two groundsmen and the other crew consisting of a foreman (the victim), equipment operator, and two groundsmen, were sent to the foundry to clear brush and weeds/grass from an area around the settling pond. The crews, although working in the same area, were hundreds of yards apart. The victim’s crew was engaged in cutting brush with a chain saw, and cutting weeds/grass with a 1995 Ford Woods Boss Tractor, pulling a brush-hog. The brush-hog was equipped with two heavy- duty cutting blades, which cut a swath 6-feet wide. Two men were assigned to cut the brush on the bank of the pond, while the other two men cut the weeds/grass on the level land at the top, and around the ground area of pond with a tractor and brush-hog. The victim was using a chain saw to cut brush on the bank while a groundsman stood at the top of the bank holding a 1-year-old 2-inch diameter, 120-feet-long, polyester and polyolefin rope that was tied around the waist of the victim.

At about 2 p.m. the victim yelled for the groundsman to assist him to work on the chain saw. The groundsman dropped the end of the rope and proceeded down the bank to assist the foreman. In the meantime, the equipment operator was driving the tractor with attached brush-hog, while the other groundsman acted as a spotter, walking ahead of the tractor and looking for debris. The spotter came upon a number of gas cans in the path of the tractor and picked them up and carried them to a pickup truck a few hundred feet away. The equipment operator continued driving toward the area where the end of the rope was lying in the weeds/grass.

The equipment operator, who did not see the end of the rope because of the height of the weeds/grass and color of the rope, which blended with its surroundings, drove over the rope. The rope became entangled around the drive shaft and blades of the brush-hog. The rope became taut and the victim was violently jerked up the bank and into the air toward the tractor (Figure). The victim hit the metal cab enclosure of the tractor, head first. After seeing the victim strike the cab, the equipment operator stopped the tractor, and he and the groundsman removed the victim from the tractor wheel. The groundsman contacted the other foreman, who called 911 for the emergency medical service(EMS). The EMS arrived in 3 minutes, evaluated the victim, and pronounced him dead at the scene.

CAUSE OF DEATH

The death certificate listed the cause of death as multiple trauma.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should review and revise, where applicable, safety procedures that address employees working in proximity to operating equipment.

Discussion: In this case a rope tied to the victim became entangled in the blades of a brush-hog that was being pulled by a tractor; this led to the death of an employee. Whenever feasible, safe distances should be maintained between operating equipment and employees. Working assignments should be reviewed prior to the beginning of any work tasks and the assignments arranged such that operating equipment and workers are separated to the maximum extent possible. Workers in proximity to operating machinery (e.g., tractor and brush-hog) are exposed to serious injury from, at the very minimum, flying objects and being struck by the equipment.

Recommendation #2: Employers should revise safe job procedures to include, but not be limited to, procedures that direct equipment operators to stop equipment when spotters are out of sight, and that all personnel work on equipment in designated areas that are free of hazards.

Discussion: Two elements that contributed to this incident were the unattended rope and the operation of the brush-hog. If safe job procedures had included instructions that directed the equipment operator to stop the tractor when the spotter was out of sight, and that equipment repairs be performed in an area free of hazards, the incident may have been prevented. If the equipment operator had stopped the tractor until the spotter was back into position, the rope may have been noticed by the spotter. Also, if the groundsman and victim had moved to an area free of hazards (e.g., on top of the bank at the groundsman’s position), rather than working on the chain saw on the bank of the settling pond, the incident may have been prevented.

Recommendation #3: Employers should provide and ensure that employees wear full body harnesses when tied off.

Discussion: A 2-inch diameter, polyester/polyolefin rope had been tied to the waist of the victim to prevent him from falling into the settling pond. In situations where a rope is needed to secure a worker, the worker should be provided with a full-body harness, and its use should be enforced by the employer. Although it probably would have not made a difference in this case, a full-body harness would distribute the force exerted over a larger area of the body experienced by a fall or sudden jerk, rather than concentrating the force in one area (e.g., spine or abdomen), thereby possibly resulting in less injury to the wearer in the event of a fall or any sudden force applied to the rope and harness.

Recommendation #4: Employers should conduct scheduled and un- scheduled safety inspections regularly at each jobsite.

Discussion: Although the company has a written safety program which includes tailgate safety sessions and quarterly district safety meetings, scheduled and unscheduled safety inspections should be conducted on a regular basis. To be effective, a safety program must be enforced at the worksite. Regular company safety inspections demonstrate to workers that the company is committed to enforcing its safety policies and procedures.

Figure.