Construction Foreman Dies After Falling From Aerial Lift Bucket Truck--South Carolina

FACE 9414

SUMMARY

On June 20, 1994, a 46-year-old male construction foreman (the victim) fell 16 feet from the bucket of an aerial lift truck. He died the following day as a result of his injuries. He had been attempting to estimate the height of telephone and television cables that were stretched across a two-lane roadway. The roadway had been guarded against moving traffic by two other employees, but just prior to the incident, the victim reassigned the employees to a different job. The victim positioned himself in the one-man bucket of the hydraulically-operated, articulated-boom, aerial lift truck and raised the bucket about 16 feet above ground level without first donning a safety belt and lanyard and attaching it inside the bucket. As the victim was judging the height of the cables, a tractor-trailer attempted to drive under the outstretched cables. The top of the trailer caught the cable and pushed it toward the victim. The cable contacted the victim’s abdomen, and knocked him out of the bucket causing him to fall to the concrete roadway. The victim was immediately rushed to the local hospital, then transferred to a trauma center. The victim died of internal hemorrhaging the following day. Although fall protection equipment (a safety belt and lanyard secured to an anchor point inside the bucket) was provided on the truck, the victim was not wearing the equipment as required by company policy.

NIOSH investigators concluded that, to prevent future similar occurrences, employers should:

- ensure that appropriate fall protection equipment is available and correctly used when working from elevations where there is a danger of falling

- review and revise, where applicable, existing safety programs

- encourage workers to actively participate in workplace safety.

INTRODUCTION

On June 21, 1994, a 46-year-old male construction foreman (the victim) died as a result of injuries sustained after falling from the bucket of an aerial lift truck the previous day. On July 23, 1994, officials of the South Carolina Occupational Safety and Health Administration notified the Division of Safety Research (DSR) of this fatality, and requested technical assistance. A DSR safety specialist traveled to the site on September 23, 1994, to conduct an investigation of the incident. During the investigation, the company’s plant superintendent was interviewed, photographs of the site and vehicle were taken, and a copy of the death certificate was obtained.

The employer was a telephone cooperative that has been in operation for 42 years and employed 220 workers, 3 of whom were construction foremen. The company’s plant superintendent managed field operations, as well as performing part-time safety responsibilities. The company maintained a written safety policy and safety rules, and employees received both formal classroom and on-the-job training. The company required pre-employment and random drug testing for employees required to drive company vehicles. Monthly safety meetings were held, quarterly safety films were shown, and speakers were hired semi-annually to present safety related topics. The victim, a journeyman line mechanic, worked as a foreman 8 of the 15 years he was employed by the company. This was the first fatality experienced in the company’s history.

INVESTIGATION

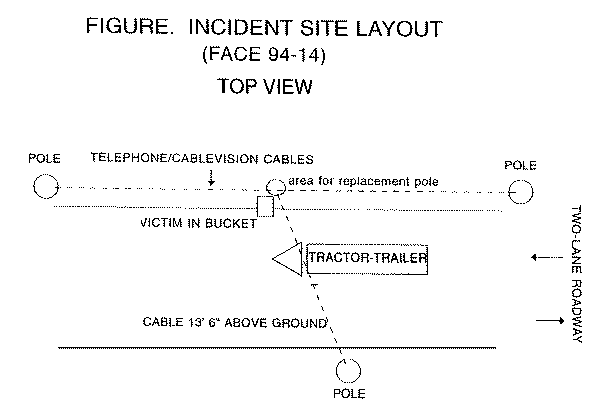

The victim and four crew members had been assigned to replace a cracked wooden utility pole located alongside a two-lane roadway. The top of the pole was about 20 feet above ground. The pole supported two sets of telephone and television cables which were strung 16 feet above the roadway. One set of cables ran parallel with the roadway; the other set ran across the roadway to a pole on the opposite side (Figure).

On the day of the incident, the victim and four other crew members arrived at the jobsite shortly after lunch in preparation to perform the routine pole replacement. Two crew members were assigned to direct traffic around the jobsite, while two other crew members and the victim used an aerial lift bucket truck and a derrick truck to remove the cables from the cracked pole and the pole itself from the ground, respectively.

After the task was completed, the cables running across the roadway were supported, in absence of the cracked pole, by the telephone and television cables which ran parallel to the road. The victim instructed the two crew members directing traffic to cease their work and help with setting the new pole. The victim stated he was going to use the bucket truck to check the height of the cables running across the roadway. Without donning the fall protection equipment provided on the truck (safety belt and lanyard which secured to an anchor point in the inside of the bucket), he entered the bucket and raised it about 16 feet from ground level to a position adjacent to where the cables running across the roadway intersected the cables running parallel with the roadway. As the victim was occupied judging the height of the cables, a tractor-trailer attempted to drive under the outstretched cables. The top of the trailer caught the cables, which were about 13 feet 6 inches above ground at that point, and pushed them toward the victim. The cable contacted the victim’s abdomen and knocked him out of the bucket, causing him to fall to the concrete roadway below. The local emergency medical squad (EMS) responded 5 minutes after notification by a paramedic who had witnessed the incident and provided first aid to the victim. The victim was transported by the EMS to a local hospital. He was later transported to a trauma center, where he died the following day.

CAUSE OF DEATH

The death certificate listed the cause of death as internal hemorrhage.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should ensure that appropriate fall protection equipment is available and correctly used when working from elevations where there is danger of falling.

Discussion: The company had provided appropriate fall protection equipment on the aerial truck, a safety belt and lanyard to be secured to an anchor point inside the bucket. However, the victim was not wearing the safety equipment while inside the bucket as required by the Code of Federal Regulations 1926.556(b)(2)(v), which states “A body belt shall be worn and a lanyard attached to the boom or basket when working from the an aerial lift.” Employers should ensure that workers follow established procedures for wearing fall protection equipment. Use of fall protection equipment may not have prevented the victim from being thrown out of the bucket, but it could have prevented his falling to the concrete roadway.

Recommendation #2: Employers should review and revise, where applicable, existing safety programs.

Discussion: Although the employer had a written safety program, there were no specific procedures regarding the management of traffic at jobsites. Prior to the incident, a temporary detour had been established around the jobsite by two workers. If the detour had been maintained by the workers, the incident may have been prevented. Consideration should be given to the review and possible revision of safety programs to include provisions that address all facets of traffic control at jobsites.

Recommendation #3: Employers should encourage workers to actively participate in workplace safety.

Discussion: Employers should encourage all workers to actively participate in workplace safety and should ensure that all workers understand the role they play in the prevention of occupational injury. In this incident, the victim boarded the aerial lift truck, entered the bucket, and raised the bucket without first donning a safety belt and lanyard and attaching it to the inside of the bucket. Workers and co-workers should look out for one another’s safety and remind each other of the proper way to perform their tasks. Employers should instruct workers of their responsibility to participate in making the workplace safer. Increased worker participation will aid in the prevention of occupational injury.

REFERENCES

29 CFR 1926.556 (b)(2)(v) Code of Federal Regulations, Washington, D.C.: U.S. Government Printing Office, Office of the Federal Register.

Figure.