Pipefitter Crushed by 5,000-Pound Shoring Plate-South Carolina

FACE 9403

SUMMARY

A 32-year-old male pipefitter (the victim) died when a 5,000-pound shoring plate fell on him as he tried to exit a 14-foot-deep by 5-foot-wide trench. The victim was a member of a 7-man crew laying an 8-inch ductile iron sewer pipeline at a residential subdivision. Approximately seven times daily, dirt was excavated for the next section of pipe. A 10-foot-high by 28-foot-long trench box was pulled forward into position in the trench and pounded down into place by two backhoe buckets. Six steel plates (7 feet, 5 inches high by 16 feet long) were then placed against the inside of the street side wall to prevent water from accumulating inside the trench box and to serve as extra protection from the water-saturated Class C soil on the street side wall of the trench. The first plate was lifted by a backhoe, guided into place by a pipefitter (the victim), then pushed down into place by the backhoe bucket in the back end of the trench box. The plate was suspended by a hook attached to cables leading to three shackles connected to an eyelet on the backhoe bucket. The other plates were then placed into the trench, each overlapping the previous plate, then pushed into place by the bucket. The pipefitter only had to guide the first plate into place. During one of these moves, the pipefitter had guided the first plate into place and signaled the backhoe operator to push it down. As the operator lowered the bucket onto the plate, the bucket slipped off the plate and the hook, which was missing its safety latch, slipped out of the hole in the plate, allowing the plate to fall toward the center of the trench. The foreman saw the plate falling and yelled to the victim, who was exiting the back of the trench box over the excavated dirt. When the victim turned toward the foreman, the plate struck him in the chest, then landed on him, causing fatal, massive crushing injuries. NIOSH investigators conclude that, to prevent similar occurrences, employers should:

- ensure that no employee travels or works under or near a lifted load

- conduct a jobsite survey before starting any work to identify any hazards, implement appropriate control measures, and provide subsequent training to employees specific to all identified site hazards.

INTRODUCTION

On September 29, 1993, a 32-year-old male pipefitter (the victim) died after being struck by a 5,000 pound-shoring plate while trying to exit a trench. On October 5, 1993, officials of the Occupational Safety and Health Administration of the state of South Carolina (SCOSHA) notified the Division of Safety Research (DSR) of this fatality, and requested technical assistance. On December 21, 1993, a DSR safety specialist traveled to the site to conduct an investigation. The incident was reviewed with the SCOSHA compliance officer assigned to the case, and the county coroner. Photographs of the site taken immediately after the incident were viewed during the investigation.

The employer was a construction company that had been in operation for 27 years and employed 20 workers, 7 at the incident site. The employer had a written comprehensive safety program and safety policy. All workers received training in subjects such as trench safety, confined space safety, fall protection, first aid, hazard communication, and other subjects pertaining to their work. A designated competent person (as defined by OSHA) was on-site. Weekly tailgate safety meetings, conducted by the crew supervisor, were held on-site. Since the incident, the employer has conducted safety/training meetings with each crew covering operations under suspended loads, working within the fall radius of suspended loads, and performing work within a trench box. The victim had worked for the employer for 14 years, the last 10 as a pipefitter. This was the first fatality experienced by the employer.

INVESTIGATION

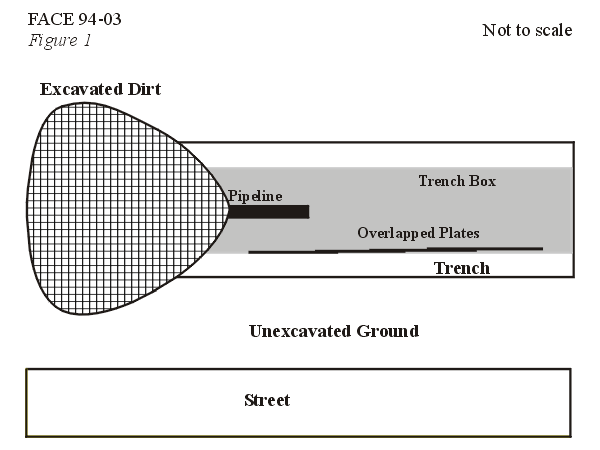

The employer had been contracted to install an 8-inch ductile iron sewer pipeline at a new residential subdivision and was 3 weeks into the job. The pipe was being installed in a 14-foot-deep by 5-foot-wide trench by a seven-man crew. The trench had been excavated in type “C” (sandy) soil that was water-saturated (water was constantly being pumped from the trench). A 28-foot-long by 10-foot-high trench box had been installed in the trench from which the men could work. Six shoring plates, measuring 7-feet, 5 inches wide by 16- feet high, and weighing 5,000 pounds apiece, were installed inside the trench on the street side of the excavation (Figure 1). These plates were overlapped over each adjacent plate and were installed to prevent ground water from accumulating in the trench and to provide additional protection from the saturated street sidewall. The plates were lifted by a hook placed in a 3¼-inch by 6-inch hole cut into the top midpoint on the short side of each plate. The hook was attached to three cables leading to three shackles connected to an eyelet on the backhoe bucket.

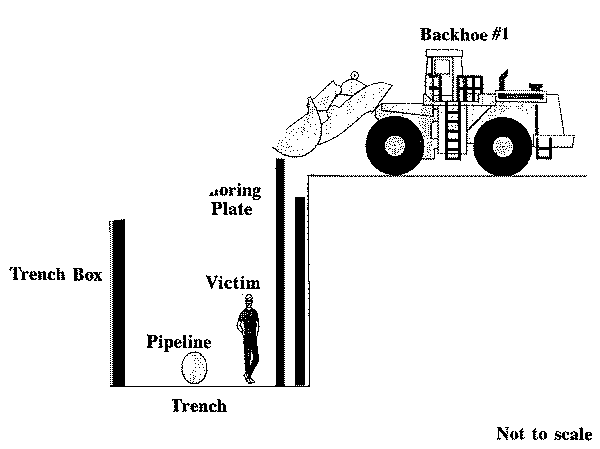

Each day the crew performed the following sequence approximately seven times. The ground was excavated for the next length of pipe. A backhoe (#1) located on the side trench and in front of the trench box pulled the trench box forward while the backhoe (#2) at the rear of the trench box backfilled the previous length of pipe. The trench box was then pounded down into position by the two backhoe buckets. The six shoring plates were then set inside the trench box on the street side of the excavation. The first plate was guided into place by a pipefitter (the victim) who entered the rear of the trench box over the excavated dirt that covered the previous length of installed pipe. After the plate was guided into position by the pipefitter, the backhoe (#1) operator would push it down into the ground using the backhoe bucket. The next five plates would then be placed in the trench box in an overlapped fashion. The pipefitter guided only the first plate into position.

At 2 p.m. on the day of the incident, the crew had just moved the trench box forward and the first plate was being positioned at the rear of the trench box (Figure 2). As backhoe (#1) began to push the plate down, the victim began to walk up the excavated dirt out of the trench box. As the bucket pushed down on the plate, it slipped off the plate and the plate began to fall toward the victim. The hook, missing a safety latch, slipped out of the hole in the plate. The foreman yelled to the victim, and the backhoe operator at the front of the trench box, seeing the plate free-falling toward the victim, blew his machine’s horn. As the victim turned, the plate struck his chest and fell on top of him, crushing him.

The plate was lifted from the victim and the foreman called the office from the company truck, requesting the emergency medical squad (EMS). The victim, breathing but unconscious, was transported to the hospital by the EMS where he was pronounced dead by the attending physician.

The operator of the backhoe (#1) lifting the plate stated during OSHA interviews that the safety latch had broken off a day or so before the incident. Replacement hooks were available in the company parts truck.

CAUSE OF DEATH

The coroner listed the cause of death as massive crushing injuries to the chest and torso.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Employers should ensure that no employee travels or works under or near a lifted load.

Discussion: OSHA regulation 29 CFR 1926.651 (e) requires that no employee shall be permitted underneath loads handled by lifting or digging equipment, and that employees stand away from any vehicle being loaded or unloaded to avoid being struck by any spillage or falling materials. Alternate means of setting the shoring plates should be evaluated in order to eliminate worker exposure to suspended loads.

Recommendation #2: Employers should conduct a jobsite survey before starting any work to identify any hazards, implement appropriate control measures, and provide subsequent training to employees specific to all identified site hazards.

Discussion: Prior to any work being performed, a jobsite evaluation should be performed by a competent person, as defined by OSHA, to identify potential hazards (e.g., the pipefitter needing to enter the trench in proximity to a suspended load, the missing safety latch on the hook) and develop control measures that would lessen or eliminate worker exposure to these hazards. Any faulty equipment should be repaired immediately or tagged and removed from service. An inspection might have identified the faulty hook. This hook could have been replaced with a new hook from the supply truck.

REFERENCES

Code of Federal Regulations 29 CFR 1926.651 (e). Office of the Federal Register, Washington, D.C. 1993.

Figure 1.

Figure 2.