Roofer's Helper Electrocuted When Ladder Platform Hoist Contacts a Powerline--South Carolina

FACE 92-24

SUMMARY

A 21-year-old roofer’s helper (the victim) was electrocuted, and a co-worker received serious electrical burns at a private residence when the metal ladder platform hoist they were positioning contacted a powerline. Prior to the incident, the victim and five co-workers had been removing old roofing materials from a single-story private residence in preparation for the application of new roofing materials. As new shingles were being applied to one side of the roof, the victim and a co-worker were instructed to set up the ladder platform hoist on the opposite side of the residence. The victim and a co-worker carried the ladder platform hoist around the side of the residence and stood it upright from ground level against the edge of the carport roof. As they positioned the ladder platform hoist, it contacted an overhead powerline, and electrical current passed through the ladder platform hoist and both workers, to ground. The victim was electrocuted and the co-worker was seriously burned. NIOSH investigators concluded that, in order to prevent future similar occurrences, employers should:

- develop and implement safety programs that are designed to enable workers to recognize, report, and avoid hazards, especially electrical hazards (e.g., overhead powerlines)

- conduct initial jobsite surveys to identify all hazards associated with each specific jobsite, and develop and implement specific methods of controlling the identified hazards.

In addition, ladder manufacturers should:

- consider the use of non-conductive materials in the manufacture of ladder platform hoists.

INTRODUCTION

On June 24, 1992, a 21-year-old male roofer’s helper (the victim) was electrocuted and a co-worker received serious electrical burns, when the ladder platform hoist they were positioning contacted an overhead powerline. On June 29, 1992, officials of the South Carolina Occupational Safety and Health Administration (SCOSHA) notified the Division of Safety Research (DSR) of this fatality, and requested technical assistance. On July 27, 1992, a safety specialist from DSR conducted an investigation of this incident. The investigator reviewed the incident with the two owners of the company, and the SCOSHA compliance officer assigned to the case. The investigator photographed the incident site, and obtained a copy of the coroners report.

The employer in this incident was a small family-owned roofing construction company that had been in business for 27 years. The company employed seven workers, including three roofer’s helpers. The company had no formal safety program, however, safety warnings were given intermittently by the owners. The victim had worked for this employer for 2 years on a part-time basis as a roofer’s helper. This incident was the second fatality the company had experienced.

INVESTIGATION

On the day of the incident, the victim arrived at the office of the roofing company and was transported, along with five co-workers, to a private residence. The company had been contracted to remove old roofing materials (i.e., felt paper, asphalt shingles, nails, etc.) from a single-story private residence and apply new ones. The roofing job was to be completed in one day.

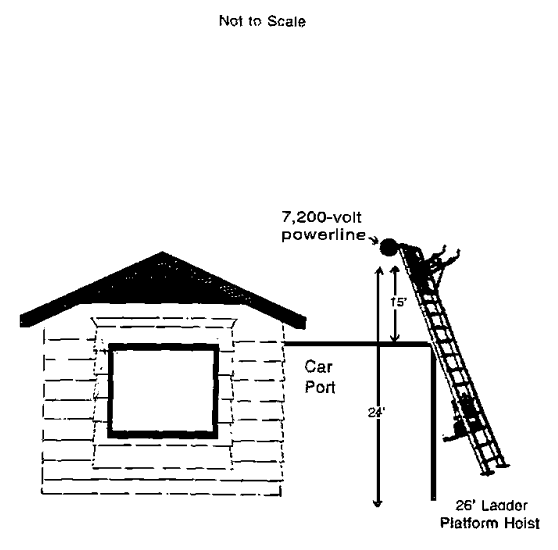

At the time of the incident, work had been in progress about 2 hours and 45 minutes. The old roofing material had been removed and new felt paper had been applied to the roof. Shingles were being applied to one side of the pitched roof when one of the company owners instructed the victim and his co-worker to reposition the ladder platform hoist from one side of the residence to the opposite side. The ladder platform hoist (i.e., a single aluminum ladder, 26-feet long, equipped with a 3 h.p. gasoline motor, pulleys, wire rope, and a metal hoist platform) was used to raise heavy loads to the rooftop. Material was placed on the platform at the bottom of the ladder and then hoisted to the rooftop by the gasoline-powered motor.

The victim and co-worker picked up the ladder platform hoist and carried it to the opposite side of the residence. A single-phase, 7,200-volt overhead powerline ran perpendicular to the house roof; it was located 15 feet above an attached carport and approximately 24 feet from ground level. The workers stood the hoist upright, leaning it against the edge of the carport roof while the feet of the ladder remained on the ground. At that time, the workers determined that the location of the hoist was incorrect and they repositioned it. It contacted the overhead powerline (Figure), electrical current passed down the ladder, and entered the victim’s hands, passing through his chest and exiting his right foot to ground, causing his electrocution. The current simultaneously entered the co-worker’s right side and exited his left foot to ground, causing serious electrical burns.

Seconds after the incident, one of the two company owners rounded the corner of the residence and saw the workers falling to the ground. A motorist driving by the residence also saw the incident, stopped his vehicle and ran to assist the workers. The company owner had the residence owner call the emergency medical service (EMS), then proceeded to give assistance to the injured co-worker, who was conscious but disoriented. The motorist checked the victim and administered cardiopulmonary resuscitation (CPR) until the arrival of the EMS, about 15 minutes later. The EMS continued CPR, and transported the victim and co-worker to the local hospital emergency room where the victim was pronounced dead on arrival, and the co-worker was admitted for treatment of electrical burns. The coroner’s report identified an electrical exit wound to the victim’s right foot.

CAUSE OF DEATH

The coroner’s report listed the cause of death as electrocution.

RECOMMENDATIONS/DISCUSSION:

Recommendation #1: Employers should develop and implement safety programs designed to enable workers to recognize, report, and avoid hazards, especially electrical hazards (e.g., overhead powerlines).

Discussion: The danger of overhead powerlines appears to be obvious; however, contact with overhead powerlines and the subsequent occupationally-related fatalities continue. OSHA Standard 29 CFR 1926.21(b)(2) states that “the employer shall instruct each employee in the recognition and avoidance of unsafe conditions and the regulations applicable to his work environment to control or eliminate any hazards or other exposure to illness or injury.” Employers should provide employees with adequate training to ensure that they can recognize potential hazardous exposures. Evidence suggests that the workers did not realize the hazard created by using a metal object (aluminum ladder platform hoist), in proximity to overhead powerlines. A safety program should be developed and implemented with particular emphasis on detailed safety procedures (specific for all tasks and job categories) that are designed to recognize, report, and avoid potential hazards. For these procedures to be effective, they must be clearly communicated and fully understood by the affected employees and supervisors. All workers must believe the company genuinely expects compliance with the procedures, and is committed to preventing occupational injury.

Recommendation #2: Employers should conduct initial jobsite surveys to identify all hazards associated with each specific jobsite, and develop and implement specific methods of controlling the identified hazards.

Discussion: The jobsite had at least one identifiable electrocution hazard (i.e., a 7,200-volt overhead powerline in proximity to the roof of the carport where work was to be performed). Energized overhead powerlines in proximity to a work area constitute a safety hazard. Extra caution must be exercised when working near energized powerlines. A safe distance between powerlines and ladders, tools, or scaffolds should be maintained at all times. 29 CFR 1926.450(a)(11) states that “portable ladders shall not be used for electrical work or where they may contact electrical conductors.” The powerline in this instance was within 15 feet of the carport roof. Before the start of any work, employers should identify any hazards that may put the worker at risk, and develop and implement specific methods of controlling the identified hazards [e.g., positioning the ladder platform hoist on the side of the residence where no possible contact with the overhead powerline could occur, or making arrangements with the local utility company to de-energize or cover the powerlines with insulating line hoses or blankets when the work must be performed within minimum safe distances as specified in 29 CFR 1926.450(a)(11)].

Recommendation #3: Manufacturers of ladder platform hoists should consider the use of non-conductive materials in the manufacture of these devices.

Discussion: The ladder platform hoist is comprised of a single aluminum ladder, 26-feet long, equipped with a 3 h.p. gasoline motor, pulleys, wire rope, and a metal hoist platform which is used to raise heavy loads. The use of non-conductive materials in the manufacture of extension ladders could provide a passive form of safety to all affected workers in the event of inadvertent contact with an energized electrical conductor (such as an overhead powerline. The use of passive safety interventions such as non-conductive materials in tools and equipment, may provide an additional level of worker protection.

REFERENCES

Office of the Federal Register: Code of Federal Regulations, Labor 29 Part 1926. p. 20. July 1, 1989.

Bellegarde, M. L. Human Factors Analysis of Aluminum Ladders/Powerlines Electrocution Hazard. U.S. Consumer Product Safety Commission: pg. 5-9, October 1988.

Figure. Ladder Platform Hoist Contacting Overhead Powerline at Private Residence