19-Year-Old Laborer Electrocuted in Kentucky

FACE 87-15

Introduction

The National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR) is currently conducting the Fatal Accident Circumstances And Epidemiology (FACE) Project, which in focusing primarily upon selected electrical-related and confined space-related fatalities. The purpose of the FACE program is to identify and rank factors that influence the risk of fatal injuries for selected employees.

On August 27, 1986, a 19-year-old laborer was electrocuted while painting a concrete silo.

Contacts/Activities

Officials of the Occupational Safety and Health Program for the State of Kentucky notified DSR concerning this fatality and requested technical assistance. This case has been included in the FACE project. On December 9, 1986, the DSR research team (a safety engineer and a statistician) visited and photographed the accident site. Interviews were conducted with the owner of the company, two comparison workers, a representative of the farm where the incident occurred, and a surrogate for the victim. The coroner was contacted and the autopsy report was reviewed.

Overview of Employer’s Safety Program

The employer is a small concrete restoration company which employed seven workers at the time of the incident. Because this work is seasonal the number of employees fluctuates accordingly.

The company does not have a safety program other than what is required to meet contractual obligations when bidding on contracts. Although this safety program is rather good on paper, it does not appear to be implemented on a daily basis.

Synopsis of Event

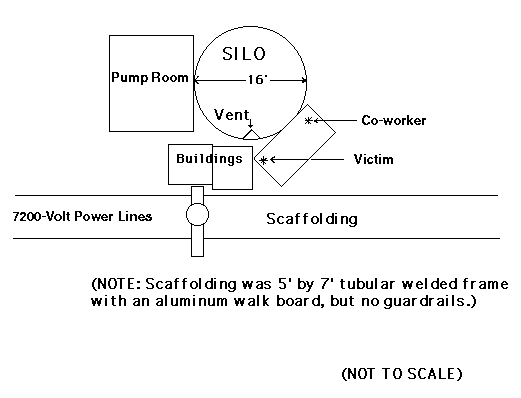

On August 27, 1987, the owner of a concrete restoration company and six employees were painting a concrete silo (65 feet high, 16 feet in diameter) that they had repaired as part of the same contract. The victim and a co-worker were painting from scaffolding along the side of the silo. The workers were approximately 23 feet above the ground and were not using any personal protective equipment. The scaffolding was erected to the top of the silo. The workers were using eight foot aluminum poles (that could be extended to 16 feet) with paint rollers attached on one end to paint the silo. The presence of the scaffolding above the employees required them to paint through the openings of the support lumbers of the scaffolding. A 7200 volt power line was located six to eight feet behind the workers and approximately 23 feet above the ground. (See Figure.)

The victim was painting a screen that covered several vent holes. This required him to stretch in order to reach the screen with his paint roller. Apparently while the victim was bringing his roller and the pole back to the scaffold to put paint on the roller, he contacted the electrical line with the aluminum pole.

The victim collapsed and the co-worker laid him on the aluminum walk boards. The owner, who was suspended from a boatswain’s chair, swung over to the scaffold and performed cardiopulmonary resuscitation (CPR) on the victim until emergency medical service (EMS) personnel responded approximately 20 minutes after the victim contacted the power line. Advanced cardiac life support was administered by responding EMS personnel; however, this was begun only after the victim was removed from the scaffolding. The victim was pronounced dead on arrival at a nearby hospital.

Cause of Death

The coroner determined the cause of death to be electrocution (high voltage). Electrical burns were noted on the victim’s right side.

Recommendations/Discussion

Recommendation #1: The employer should not erect scaffolds within ten feet of electrical power lines. Electrically conductive tools should not be used where they may come into contact with electrical power lines.

Discussion: Although there are no Federal regulations concerning working a specified distance from energized power lines, several states have requirements concerning this activity. Additionally, employees should not be allowed to use electrically conductive tools when working in the vicinity of electrical power lines. Erection of the scaffolding and the use of the aluminum pole within six to eight feet of the power line is inherently dangerous and should not be permitted. The aluminum poles had warning signs concerning their use around electrical lines; however, these warnings were not heeded.

Recommendation #2: Employers should thoroughly evaluate the safety concerns of their employees and take any necessary corrective action.

Discussion: Prior to the accident, employees notified the owner of the company that they were receiving shocks while working on the silo. The owner investigated the situation and determined that the shocks were resulting from voltages induced on the silo by the nearby power lines. This explanation is plausible given the voltage and proximity of the power line. Employers should thoroughly evaluate the safety concerns of their equipment. Many states provide free safety consultation to employers and utilities often provide advice concerning electrical matters. Either of these organizations may have been able to adequately explain this phenomenon and may have identified the even more serious hazard presented by the proximity of the power line to the silo.

Recommendation #3: Autopsy reports and other technical reports resulting from an incident of this kind should be explained by qualified personnel in the medical examiner’s office to lay people who are provided copies.

Discussion: Many witnesses interviewed were confused concerning the events surrounding this incident. This confusion was exacerbated by the clinical terminology used in the autopsy report and a misunderstanding of the details of that report. The only electrical burns identified were on the victim’s right side. These burns resulted from arcing between the victim’s body and the aluminum pole and could only result if high voltage was present. A scorch mark was noted on the victim’s right shoe; however, there were no electrical burns on his feet, hands, or head. All other marks identified in the autopsy report refer to marks that would normally result from the medical treatment provided to the victim and do not have any role in the events surrounding the actual contact with electricity.

Recommendation #4: Guardrails should be installed on the level of scaffolding where employees are working.

Discussion: OSHA regulation 1910.28(d)(7), Tubular welded frame scaffolds requires that guardrails be installed on the level of the scaffolding where employees are working. The employees were working with scaffolding above them and were using the structural supports as guardrails. Guardrails that comply with the above referenced standard should have been installed.

Recommendation #5: Employers that provide their own electrical distribution system should periodically have those systems evaluated by personnel qualified to determine if these systems were installed and are being maintained in accordance with all applicable safety requirements.

Discussion: The farm owner (i.e., the owner of the electrical lines) purchases electricity from the utility and is responsible for distribution throughout the farm. A private electrician is contracted to perform maintenance and repairs on the electrical system; however, it appears that this arrangement does not provide an adequate level of safety for systems similar to the one involved in this incident. The line was located six to eight feet from the silo and almost directly above three small buildings that house pumps and other equipment associated with the silo. Employers that provide their own electrical distribution systems should periodically have those systems evaluated by qualified personnel to determine if these system are being installed and maintained in accordance with all applicable safety requirements.

Figure. Top View of Fatality Site