Chainsaw Operator Dies After Being Struck by Excavator Bucket During Site Clearing - North Carolina

NIOSH In-house FACE Report 2004-07

December 23, 2004

Summary

On July 27, 2004, a 46-year-old chainsaw operator (victim) was cutting root balls from trees pushed over during site clearing, when he sustained fatal crushing injuries after being struck by the bucket of a track-mounted hydraulic excavator. The excavator operator was using the bucket on the excavator to push over trees, straighten downed trees for stumping, and move damaged trees to a large burn pile. When he realized he had not seen the victim for approximately 15 minutes, he moved the excavator to get a better view of the area and saw the victim on the ground. He jumped out of the excavator and ran to the victim. Unable to get a response when he called to the victim, he ran to his employer who called 911 on his cell phone. The employer drove to the main road to help emergency medical service personnel (EMS) locate the incident site. Police officers responded within minutes and the excavator operator accompanied them to the incident site. The victim was pronounced dead at the scene at 10:30 a.m. by EMS personnel.

NIOSH investigators concluded that, to help prevent similar occurrences, employers should

- ensure that the phases of work are planned and executed to minimize the exposure of workers on foot to moving equipment

- ensure that excavator operators and workers on foot maintain visual or audible contact at all times

- develop, implement, and enforce a comprehensive written safety program for all workers which includes training in hazard recognition and the avoidance of unsafe conditions. A written training plan should require training for all excavator operators that includes the equipment manufacturers’ recommendations for safe equipment operation, and should require appropriate training for workers engaged in site clearing and logging operations.

- provide workers with appropriate personal protective equipment (PPE) and ensure its use.

Additionally,

- general contractors should ensure through contract language that all subcontractors have appropriate safety programs and training specific to the work to be performed.

Introduction

On July 27, 2004, a 46-year-old chainsaw operator (victim) was cutting root balls from trees pushed over during site clearing, when he sustained fatal crushing injuries after being struck by the bucket of an excavator. On August 12, 2004, the North Carolina Occupational Safety and Health Administration (NCOSHA) notified the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR) of the incident. On August 17, 2004, a DSR safety and occupational health team met with the NCOSHA compliance officer assigned to the incident. The DSR team accompanied the NCOSHA compliance officer to the site, took photographs, and interviewed a landscaping subcontractor who had been working at the site on the day of the incident. The DSR team interviewed the victim’s employer by phone on August 18, 2004. The excavator operator was not available for interview. The police report and medical examiner’s report were reviewed. The cause of death was obtained from the medical examiner.

Employer: The victim’s employer was a grading and hauling subcontractor. According to the employer, he was hired to clear the site because the general contractor had not been able to find a logging company to log the trees (primarily pines about 12 inches to 18 inches in diameter and 28-30 feet high) on a 14 acre site. His typical work consisted of grading and hauling operations, but clearing a few trees on residential building sites was done on occasion. The company employed 7 workers and had worked exclusively for the general contractor over an 8 year period, six weeks at the incident site. The company had no safety and health program and no documentation of employee training. There was no written agreement between the general contractor and the subcontractor regarding safety issues.

Victim: The victim worked for the subcontractor for 2 months as a chain saw operator. He had worked six weeks at the incident site. His job was to cut the root balls from downed trees and to cut the trees in to sections. His previous employment experience and training is unknown.

Equipment: The hydraulic excavator had been purchased by the grading subcontractor and was five years old. The excavator’s reach capacity was between 32 and 34 feet at ground level. A hydraulic thumb (photo 1) had been attached to the excavator so that it could be used for handling felled trees. The equipment operator had been employed by the company for 7 years and operated this excavator and other heavy equipment on a regular basis.

Personal protective equipment: The employer had a truck on site in which several hard hats, hard hats with face guards and ear muffs (hearing protection), and a pair of chaps for leg protection were located. This was the employer’s first fatality.

Back to Top

Investigation

The incident site was being developed into a recreational sports complex with both indoor sports facilities and outdoor ball fields. On the day of the incident, two subcontractors were working on the land: a landscaping subcontractor who was involved with a roadway inspection at one end of the 14-acre property and the grading and hauling subcontractor who was working with a crew of two employees (excavator operator and victim) doing site clearing at the other end. The grading and hauling subcontractor and his crew had cleared brush and 28-30 foot pine trees from 10 acres and was ahead of schedule, with 4 acres remaining to clear.

According to the grading and hauling subcontractor, his employees rode to work together from his shop located about 50 miles away. Work typically began at 7:30 a.m. and ended at 5:00 p.m., Monday through Friday. On the day of the incident, work began at 7:30 a.m. While his two-man crew started site clearing, he drove to another worksite, returning at approximately 9:45 a.m. The victim spent his first hours of the day cutting root balls (stumping) from downed trees with a chain saw. He wore a shirt, blue jeans, hiking boots, and a baseball cap. He was not wearing any type of personal protective equipment. The excavator operator reported to the NCOSHA compliance officer that he took down trees the first few hours of the day, moving ones that were to be burned to the burn pile and straightening others so they could be stumped by the victim. When he got to a location where he thought the victim might be in danger, he would blow the horn, open the door and holler for him to move.

The victim and excavator operator took a 10 minute break at about 9:30 a.m. After their break, the victim returned to cutting stumps and the excavator operator walked approximately 300-400 feet away to help put oil in the bulldozer that his employer was preparing to operate. The employer then started to push brush toward the burn pile with the bulldozer. The excavator operator reported to NCOSHA and police investigators that after he helped his employer, he got back on the excavator and resumed work pushing over trees, lining up trees for stumping, and moving waste to the burn pile. After about 15 minutes, he realized he had not seen the victim since he had resumed work. He moved the excavator forward and turned it to the left and saw the victim’s foot through the side window of the excavator. He set the bucket on the ground and got off the excavator and ran to the victim calling his name. Unable to get a response from the victim, he ran to his employer who called 911 on his cell phone. It was approximately 10:22 a.m. The employer drove to the main road to help EMS personnel locate the incident site which was approximately 1/8 mile off the main road. Police officers responded within minutes and the excavator operator accompanied them to the incident site. One of the responding firemen indicated he was first on the scene and noted that the victim appeared to be dead. He was lying on his side with his body doubled over at the waist and his torso appeared compressed. EMS personnel responded and determined that the victim had died. The victim was pronounced dead at the scene at 10:30 a.m. by EMS personnel.

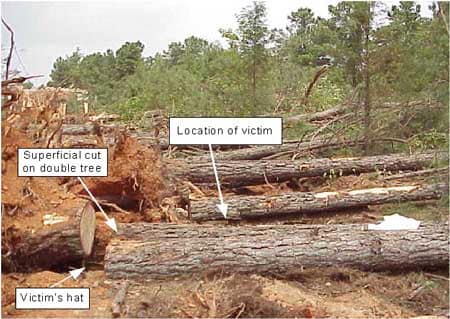

According to statements taken from those who responded to the incident, the victim’s body was found beside a downed double tree (two trees on one root ball). One of the trees on the double tree had been cut from the stump and the other had a superficial saw cut on it. The chain saw was located under the victim’s body as was a large limb. The switch was in the “on” position and the chain brake was not engaged. The employer reported that he thought the double tree may have rolled and struck the victim when it became unbalanced after the victim had cut one of the trees on the double tree. The excavator operator told the NCOSHA compliance officer that he did not believe he had struck the victim with the bucket.

Photographs of the site taken immediately after the incident indicate that the victim’s body was found in an impression approximately 18-20 inches deep. There was a downed double tree with a large single root ball between the victim and the excavator. It is unlikely that the victim was visible to the excavator operator because of the site characteristics and because the victim wore dark clothing and was bending over to cut downed trees. Distance estimates made by NCOSHA indicate that the victim’s body was located within reach of the excavator bucket. Police personnel noted marks on the victim’s body that they believed were made by the bucket of the excavator.

Back to Top

Cause of Death

The medical examiner’s office reported that the cause of death was blunt force injuries due to a backhoe accident.

Back to Top

Recommendations/Discussion

Recommendation #1: Employers should ensure that the phases of work are planned and executed to minimize the exposure of workers on foot to moving equipment

Discussion: The site clearing and tree harvesting work conducted on the incident site involved pushing over trees and brush with an excavator bucket and separating downed trees that were to be cut and sold for saw timber from those that would be burned as waste. Employers should inspect the worksite and plan work tasks in phases to eliminate the need for workers on foot, such as chain saw operators, to be working in an area where machines are being operated. All phases of work should be planned to maintain required distances between workers and machines and between various machines operated on site. NCOSHA has a special emphasis program (SEP)a for tree felling and related activity that identifies the federal OSHA logging standard as applicable to the type of work performed in this incident.1

OSHA Logging standard 29 CFR 1910.266 (d)(6)(i) requires that employees be spaced and the duties of each employee shall be organized so that the actions of one employee will not create a hazard for any other employee; 29 CFR 1910.266 (f)(2)(vii) requires that machines be operated at such a distance from employees and other machines such that operation will not create a hazard for an employee.2

Recommendation #2: Employers should ensure that excavator operators and workers on foot maintain visual or audible contact at all times

Discussion: Visual or audible contact must be maintained at all times to ensure that safe distances are maintained between work areas and to provide an opportunity to communicate information regarding working conditions. Employers can ensure that workers understand this requirement for continuous verbal or visual contact by requiring crews to discuss maintaining continuous verbal or visual contact each day before beginning work. OSHA standard 29 CFR 1910.266 (d)(6)(iii) requires that each employee performing a logging operation at a logging work site shall work in a position or location that is within visual or audible contact with another employee.2

Recommendation #3: Employers should develop, implement, and enforce a comprehensive written safety program for all workers which includes training in hazard recognition and the avoidance of unsafe conditions. A written training plan should require training for all excavator operators that includes the equipment manufacturers’ recommendations for safe equipment operation, and should require appropriate training for workers engaged in site clearing and logging operations.

Discussion: A comprehensive written safety program should be developed for all workers that is in compliance with applicable OSHA standards and includes training in hazard recognition and the avoidance of unsafe conditions. It should then be noted in a company’s comprehensive safety program that certain types of training are required and when completed, the training should be documented. For example, excavator operators should be trained to use the equipment they are assigned to operate according to the manufacturer’s specifications and recommendations. Workers on-site should be trained to remain outside the established swing area and blind spots of excavators.

Additional information useful for training workers about hazards involved with excavator use can be found in the NIOSH Workplace Solutions: Preventing injuries when working with hydraulic excavators and backhoe loaders3 available through the NIOSH web site at https://www.cdc.gov/niosh or by calling 1-800-356-4674.

The equipment manufacturers’ operating manual should always be kept on the equipment and should be included in training for equipment operators. The hydraulic excavator safety manual developed by the Construction Industry Manufacturer’s Association (CIMA)4 can also be used to supplement and reinforce safety training found in the manufacturers’ operators manual. For example, CIMA recommends that excavator operators “KNOW THE WORKING RANGE OF THE MACHINE. Be sure everyone is in the clear before swinging or moving in any direction. NEVER swing or position attachment or load over personnel or vehicle cabs. Never allow personnel to walk or work under any part of the machine or load while the machine is operating.”

Workers performing site clearing and logging operations should be trained to recognize and avoid hazards associated with site clearing and logging operations. Safety regulations can be found in 29 CFR 1910.266 Logging operations.2 OSHA requirements for training loggers are very specific and employers are required to certify compliance with employee training [29 CFR 1910.266 (i) (1-11)].2 Appropriate safety training may have helped the excavator operator and chain saw operator (victim) avoid hazards associated with working near moving machinery, and hazards associated with stumping a double tree that may roll toward a chain saw operator after one part is cut free. The OSHA compliance officer observed the site shortly after the incident and reported to DSR investigators that it appeared that the double tree had rolled toward the victim.

Additional information useful for training workers about hazards involved with logging operations can be found in the NIOSH Alert: Preventing injuries and deaths of loggers5 available through the NIOSH web site at https://www.cdc.gov/niosh or by calling 1-800-356-4674. The worker/employer summary sheet can be posted at the worksite or given to workers and may serve as an additional means to communicate safe work practices to workers. OSHA has developed a free internet-based training program for safety compliance with logging standards that may serve as yet another means to communicate safe work practices to loggers. This logging e-tool is available at https://www.osha.gov/SLTC/logging/index.htmlexternal icon.6

Recommendation #4: Employers should provide workers with appropriate personal protective equipment (PPE) and ensure its use.

Discussion: Employers should require employees to wear a high-visibility vest or high-visibility clothing while working on a tree harvesting or site clearing operation to help increase their visibility.7,8 The CIMA4 hydraulic excavator safety manual recommends that excavator operators “always wear required protective equipment such as hard hats, safety glasses, reflective clothing, safety shoes, and ear protection, as required.” OSHA requires employers to provide chain saw operators with leg protection constructed with cut-resistant material and with foot protection that is cut resistant. Additionally, employers must provide head, eye and face protection as well as hearing protection. PPE should be inspected before initial use and before each work shift. OSHA requirements for PPE in logging operations are located in 29 CFR 1910.266 (d)(1)(i-vii).2

Recommendation #5: General contractors should ensure through contract language that all subcontractors have appropriate safety programs and training specific to the work to be performed.

Discussion: General contractors should require all subcontractors to identify how they intend to implement a site-specific safety and health program prior to starting work and make this part of the subcontract language. The subcontractors’ safety and health program should be consistent with the work to be performed and, at a minimum, meet all applicable OSHA regulations.

a The scope of the tree felling SEP, identified as Operation Procedure Notice (OPN) 88D, specifies that “Logging activity includes limbing, bucking, marking, and cutting logs to length as well as tree felling. Other operations covered by the OPN include, but are not limited to, tree trimming, felling of trees in preparation for the construction of roads or structures, clearing for agricultural activity, saw milling, and storm debris cleanup and removal.” Applicable Standards: “Employers who remove trees wholly or in part for which there is a commercial use for the wood are covered by the 29 CFR 1910.266 logging standard. Employers covered by this standard include but are not limited to loggers, arborists, and construction companies doing clearing of construction sites where there is a commercial use of the wood.”

Back to Top

References

- The North Carolina Department of Labor, Division of Occupational Safety and Health, Operational Procedure Notice 88D, Raleigh, North Carolina, June, 1988.

- Code of Federal Regulations [2004]. 29 CFR 1910.266. Logging Operations. Washington DC: U.S. Government Printing Office, Office of the Federal Register.

- NIOSH [2004]. NIOSH Workplace Solutions: Preventing injuries when working with hydraulic excavators and backhoe loaders. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 2004-107.

- CIMA [1986]. Hydraulic Excavator Safety Manual for Operating and Maintenance Personnel. Milwaukee, WI: Construction Industry Manufacturers Association Form HE-60-1.

- NIOSH [1995]. NIOSH Alert: Preventing injuries and deaths of loggers. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 95-101.

- OSHA [1998]. OSHA Logging eTool. [https://www.osha.gov/SLTC/logging/index.htmlexternal icon]. Date accessed: December 1, 2004.

- Fallers’ & Buckers’ Handbook 2001 edition. Workers’ Compensation Board of British Columbia, Vancouver, BC.

- ANSI/ISEA [1999]. American National Standard for high-visibility safety apparel. New York, NY: American National Standards Institute, ANSI/ISEA 107-1999.

Back to Top

Investigator Information

This investigation was conducted by Doloris N. Higgins, Safety and Occupational Health Specialist, Fatality Investigations Team, Surveillance and Field Investigations Branch, Division of Safety Research; and Gerard de Guzman, MD, Occupational Medicine Resident at West Virginia University School of Medicine assigned to NIOSH, Division of Safety Research, Special Studies Team.

Back to Top

Photographs

|

|

| Photo 2. This photo illustrates the location of the victim next to a double tree that rolled. The excavator is not pictured but was located on the root ball side of the downed trees [Photograph courtesy of NCOSHA]. |

In-house Reports