Roadway Construction Worker Dies From Crushing Injuries When Backed Over by a Dump Truck - Virginia

NIOSH In-house FACE Report 2002-06

April 15, 2004

Summary

On January 29, 2002, a 34-year-old roadway construction worker (the victim) was killed when he was backed over by a dump truck. (Photo right) The victim was walking along the side of a road grader picking-up centerline lane reflectors when a dump truck loaded with asphalt backed over him. When notified by CB radio that the paving machine was ready for him, the driver exited the staging area, entered the work zone and started backing-up towards the paving machine. As he backed, he reported that he did not see the victim and thought that the victim had moved out of the way. While backing, the dump truck operator said that he heard a voice over his CB radio yelling for him to stop because he had hit someone. Instead of stopping, the truck driver moved his truck forward approximately 20-feet, and again was told to stop because he had hit someone. Local Emergency Medical Services (EMS) responded within minutes. EMS determined that the victim was deceased and contacted the county coroner who pronounced the victim dead at the scene.

NIOSH investigators concluded that, to help prevent similar incidents, employers should:

- ensure that workers on foot remain clear of moving equipment by developing and utilizing an “Internal Traffic Control Plan” for each highway and road work project

- consider the use of electronic signaling devices or sensors to warn equipment operators of workers on foot in the immediate work area

- ensure that during planning phases of roadway construction projects, staging areas are planned so as to minimize backing distances through workzones

- consider the use of a spotter for assistance when backing trucks into a work zone

- ensure that all workers on site are trained to follow standard operating procedures for entry and exit in the workzone

- ensure that work is scheduled to allow for sufficient rest periods for workers

Introduction

On January 29, 2002, a 34-year-old roadway construction worker (the victim) was killed when he was backed over by a dump truck. On February 8, 2002, the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR) was notified of the incident by the Virginia Department of Labor and Industry, Occupational Safety and Health Administration (VOSHA). On March 7, 2002, a DSR Occupational Safety and Health Specialist met with the VOSHA compliance officer to discuss the case and to review information collected during the course of his investigation, including the employer’s safety program and safety records. The incident site was visited, however, work had since been completed on the paving project and the employer had left the area.

The employer was a large paving company that had operations throughout the South. There were approximately 200 employees working in the Virginia Division of this paving company, 20 of whom were assigned to complete the paving contract where the incident occurred. Because paving is seasonal work, the victim had been employed off and on by this paving company since July 1991. His most current employment cycle began in March 2001. The employer provides both formal classroom training and informal toolbox safety talks to employees. The various types of training which employees receive is documented. The employer has a full-time Safety Director, who was not onsite at the time of the incident. The site supervisor, on site at the time of the incident, was responsible for site safety. The driver of the dump truck was self-employed as an independent trucker.

Back to Top

Investigation

The paving company that employed the victim was contracted by the State of Virginia to resurface several miles of a two-lane state roadway that intersects entry and exit ramps for a interstate highway. Work on the resurfacing project was into its second week and nearing completion. On the day of the incident, a crew of approximately 20 workers started work at the resurfacing site at approximately 7:00 am. Most of these workers, including the victim, were at the site until 1:00 am the night before the incident preparing the site for paving operations.

|

|

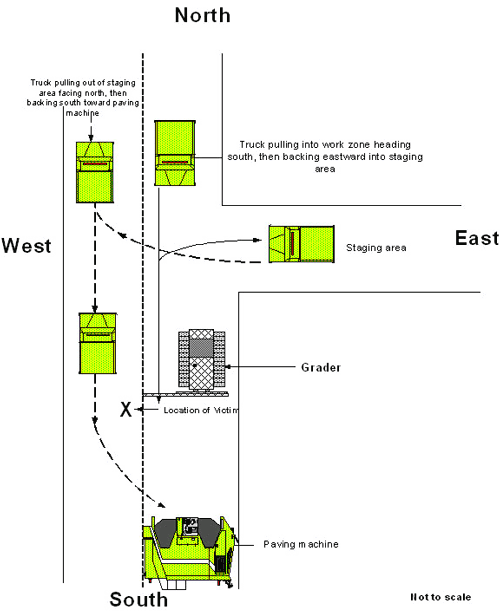

Photo 2. Workzone layout

|

The work zone was set-up according to the Manual on Uniform Traffic Control Devices (MUTCD) for a typical two-lane paving operation.1 The work zone was established so that trucks hauling asphalt would enter the work zone from the road north of the paving operations (Photo 2). The trucks would then back into a private staging road (facing west) that intersected the work zone and sit waiting their turn to back and unload at the paving machine. When called by CB radio to unload at the paving machine, a truck would pull out of the private staging road with its front facing north and back-up (south) towards the paving machine and unload (Diagram). After unloading, the truck would drive forward to leave the site. The paving process was to continue until resurfacing operations reached the interstate entry and exit ramps, which at the time of the incident, were only a few hundred yards away to the south.

|

|

Diagram. Overhead view of the interior workzone

|

In prepping the roadway for resurfacing, the victim was assigned to assist in removing the centerline lane reflectors. To remove the embedded reflectors, a road grader was used to pop the reflectors free. The grader operator would lower the grader blade on the reflector and dig it free from the preexisting asphalt. The road grader was in the northbound lane traveling south, and the victim was observed to be approximately 3-feet inside center of the southbound lane (Photo 3). Once the reflector was free, the victim would pick it up from the ground and deposit it in a bucket on the grader.

|

|

Photo 3. Approximate location of victim near grader.

|

At approximately 10:20 am, a dump truck loaded with asphalt entered the work zone and deviated from the established vehicle entry and exit pattern. The truck entered the work zone driving in the southbound lane, and drove directly up to and in front of the victim. The truck driver reported that he deviated from the established vehicle entry pattern in order to get the victim’s attention because he had thought that the victim was standing in a bad location. The driver reported that he made eye contact with the victim, thinking that he had alerted the victim that he would be backing into the work zone. He then reversed his truck and backed towards and into the private roadway staging point. When notified by CB radio, the driver repositioned his truck by pulling out into the work zone and started backing-up towards the paving machine. He reported that he did not see the victim and thought that the victim had moved as he started to back his truck. While backing, he said that he heard a voice over his CB radio yelling for him to stop because he had hit someone. The backing truck had struck the victim, who fell under the truck. As the truck continued to back-up, the victim was dragged approximately 22 feet. Instead of stopping, the driver pulled his truck forward approximately 20 feet, now dragging the victim forward. He again heard a voice yelling for him to stop. When he finally came to a stop, he exited the truck as other workers rushed to the aid of the victim. The victim could not be freed from under the truck by co-workers. EMS was called by another truck driver and responded to the site within minutes. EMS staff assessed the victim’s condition as being deceased and contacted the county coroner, who pronounced the victim dead at the scene.

The truck’s back-up alarm was tested by police and VOSHA and found to be in working order. Sound pressure measurements taken of the alarm were 76 dB(a) at the rear of the truck, and 60 dB(a) measured 20-feet from the rear of the truck. Sound pressure measurements taken next to the road grader, at the approximate location where the victim was standing, measured 89 dB(a), louder than the truck’s back-up alarm. From that testing it was concluded by police and VOSHA that the victim most likely did not hear the truck’s back-up alarm until it was too late to move out of the path of the truck.

Back to Top

Cause of Death

The coroner listed the cause of death as multiple traumatic injuries due to compression by a dump truck.

Recommendations and Discussion

Recommendation #1: Employers should ensure that workers on foot remain clear of moving equipment by developing and utilizing an “Internal Traffic Control Plan” for each highway and road work zone project.

Discussion: The “Internal Traffic Control Plan” (ITCP) defines processes and procedures for worker safety within the work zone. The elements of the ITCP should indicate where and how construction equipment, vehicles, and workers on foot interact within the work zone. The plan must also take into consideration the changing aspects of a work site and possible emergency situations that might occur.

The victim in this incident was a worker on foot walking along the side of a road grader, assisting the grader operator in the removal of reflective road markers. Due to the size of the grader, the victim was forced to walk in the lane of the road designated for trucks backing toward the paving machine, exposing himself to moving vehicles. Road surface preparation (in this case removing reflectors) should be done during periods of limited activity, such as in the evening prior to the incident, provided adequate lighting was present. In this instance, procedures called for backing the loaded asphalt trucks long distances in proximity to other construction vehicles and heavy equipment. During the planning phases of construction projects, alternative methods of removing the reflective markers should be evaluated to determine the safest possible method to be used that would not involve the use of heavy equipment, and/or conditions that would minimize the exposure of a worker on foot to moving equipment and vehicles. Additional safety information and recommendations for protecting roadway construction workers can be obtained from the NIOSH document entitled “Building Safer Highway Work Zones: Measures to Prevent Worker Injuries from Vehicles and Equipment.” 2

Recommendation #2: Employers should consider the use of electronic signaling devices or sensors to warn equipment operators of workers on foot in the immediate work area.3

Discussion: Workers on construction sites often work in close proximity to moving heavy equipment. Being exposed on a daily basis to the noise and warning devices of backing equipment can desensitize individuals to the presence of such vehicles. Other devices such as a strobe light or different noises should be considered as additions to the standard back-up alarm to warn workers of a backing vehicle. There are also devices available that can detect the presence of persons in the blind spots of vehicles and provide a warning to the driver. These additions should be considered especially when the standard practice has failed.

Recommendation #3: Employers should ensure that during planning phases of roadway construction projects staging areas are planned so as to minimize backing distances through work zones.

Discussion: In this incident, paving operations were moving away from the staging area as work progressed, increasing the backing distances for the truck drivers. At the time of the incident, the truck driver was backing an approximate distance of 200 feet past other vehicles, machines and workers on foot. During the planning stages of roadway construction projects, employers should ensure that truck staging areas are ocated in such a manner that backing distances are minimized. This might entail the use of multiple staging areas, but would reduce the exposure of workers on foot and other machinery in work zones to backing trucks.

Recommendation #4: Employers should consider the use of a spotter for assistance when backing trucks into a work zone.4

Discussion: In highway and roadway construction, it is a routine practice for large construction vehicles to continually move in and out of the work zone. When a truck backs up in a busy work zone, there is increased risk of an incident or injury to workers on foot, the driving public, pedestrian traffic, and to construction vehicles within the work zone. The highway/roadway construction work zone can be a very confined and congested space. Truck drivers and other equipment operators must adhere to established routes and need to be observant and aware of activities, vehicles, and people that may interfere with their ability to safely complete their task. One option to better manage trucks and other construction equipment backing up in the work zone is to use a spotter. A spotter can help the truck driver or equipment operator safely maneuver in and out of the work zone. The spotter provides the “vision” that the driver does not have when backing up and helps reduce “blind spots”.

Recommendation #5: Employers should ensure that all workers on site are trained to follow standard operating procedures for entry and exit in the work zone.

Discussion: Although not identified as a definite factor in this incident, the driver deviated from standard procedures for entry into the work zone. All truck drivers on site had been instructed as to the route to be taken upon entering the work zone. When the truck driver entered the work zone he deviated from the standard operating procedures followed by the other drivers. The victim might not have been aware of the exact route the driver was taking or that he was exposed to the back-over hazard. Any deviations from the standard operating procedures should be discussed with all workers within the work zone prior to the beginning of work or during work stoppages.

Recommendation #6: Employers should ensure that work is scheduled to allow for sufficient rest periods for workers.

Discussion: Though insufficient information precluded the identification of the possible role of fatigue as a factor in this incident, the schedule of work periods only six hours apart raises concerns as to the ability of workers to get sufficient sleep or rest before resuming work. Whenever possible, work should be scheduled in such a manner as to allow for sufficient rest periods for workers.

Back to Top

References

- FHWA [2000]. Manual on uniform traffic control devices millennium edition. U.S. Department of Transportation, Federal Highway Administration (FHWA).

- Pratt SG, Fosbroke DE, Marsh SM [2001]. Building Safer Highway Work Zones: Measures to Prevent Worker Injuries from Vehicles and Equipment. Cincinnati, OH: U.S Department of Health and Human Services, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health (Pub. No. 2001-128).

- California Department of Health Services [2000]. A Construction Inspector Dies after Being Backed Over by a Ten-wheel Asphalt Dump Truck – California. California Fatality Assessment and Control Evaluation (FACE) Report No. 00CA05.

- Washington Department of Labor and Industries [1999]. Flagger Killed When Struck by a Dump Truck During Road Construction, in Washington State. Washington Fatality Assessment and Control Evaluation (FACE) Report No. 99WA70.

Investigator Information

This investigation was conducted by Joseph E. Burkhart, Safety and Occupational Health Specialist, NIOSH Division of Safety Research, Surveillance and Field Investigation Branch, Fatality Assessment and Control Evaluation Team. The report was finalized by Virgil Casini, Senior Investigator, NIOSH Division of Safety Research, Surveillance and Field Investigation Branch, Fatality Investigations Team.

In-house Reports