Sudden Roof Collapse of a Burning Auto Parts Store Claims the Lives of Two Fire Fighters--Virginia

FACE 9617

INTRODUCTION

On March 18, 1996, two male fire fighters (38-and 32-years-old) died while fighting a fire in an auto parts store. On April 8, 1996, the International Association of Fire Fighters (IAFF) notified the Division of Safety Research (DSR) of the fatalities, and requested technical assistance in investigating the circumstances of the deaths of these two fire fighters. On April 15, 1996, the Chief of Trauma Investigations Section traveled to Virginia to conduct an investigation of this incident. Meetings were conducted with Virginia OSHA personnel, the fire department battalion/fire marshall, fire department investigators, fire fighters involved in the incident, and the IAFF union representative. Copies of photographs of the incident site and the transcription of dispatch tapes were obtained, and a site visit was conducted.

The fire department involved in the incident serves a population of 183,000 in a geographic area of 350 square miles. The fire department is comprised of approximately 320 workers, of whom 258 are fire fighters. The fire department provides all new fire fighters with the basic 13-week training at the fire academy, and requires 2 hours additional on-the-job training per shift. The daily training scheduled is developed by the training officer and is sent to all stations. The required training is designed to cover fire department operation, e.g., ladder training, aerial operations, hose training, breathing apparatus, etc. The written standard operating procedures manual was reviewed and appears to be complete.

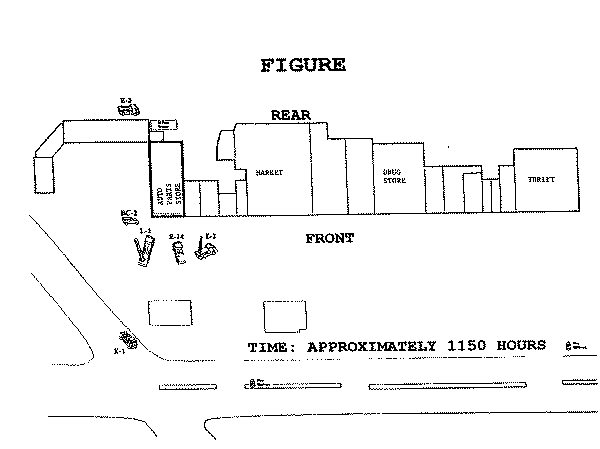

The site of the incident (auto parts store – measuring 50 feet by 120 feet) was located in a strip mall which was built in 1984. Most of the stores in the mall were built with masonry walls and steel trusses. However, the auto parts store had wooden 2-by 6-inch trusses that spanned the 50-foot width. The store had three heating-ventilation-air-conditioning (HVAC) units mounted on the roof, with an estimated total weight of 3000 pounds (Figure).

Although several fire companies were involved in this incident as shown in the Figure, only those directly involved up to the time of the fatal incident are cited in this report.

INVESTIGATION

On March 18, 1996, at 1129 hours, a call came into the fire/police dispatcher from an auto parts store in a strip shopping mall, reporting sparking and popping from an inside “fuse box”. Engine 3, Engine 1, Ladder 2, and Battalion 2 were ordered to respond. Engine 3 was the first on the scene (1135 hours) and assumed command. When Engine 3 pulled up in front of the auto parts store, no smoke or fire was visible.

It was not known to the fire fighters arriving on the scene, that the reported sparking in the fuse box was caused when the boom of a power company truck had accidentally broken the neutral line on the 208/120 volt three-phase service drop to the auto parts store. An investigation conducted by the power company revealed the panel box in the auto parts store was improperly grounded; therefore, when the neutral was broken, the power surge did not go to ground at the panel box; it traveled throughout the electrical circuitry causing electrical fires at each circuit connection. For example, the electric hot water tank caught fire and the wiring in electrical junction boxes of the HVAC units on the roof of the store were fused together from the extreme heat created by the short-circuit.

The Acting Lieutenant and a fire fighter specialist entered the front door of the store to investigate, while the driver of Engine 3 went to the side door. Although the lights were off in the store, the large plate glass windows in the front provided enough light in the store to see there was not any smoke inside the store, and that “it looked clear.”

At 1137 hours, the driver of Engine 3 heard the Acting Lieutenant calling on the radio (Portable 3), so he went back to the Engine, and received instructions from Portable 3 to reposition the Engine to the rear of the building. While driving the Engine to the rear of the building, the driver noticed a little smoke coming from the edge of the roof, and also heard the transmission from Portable 3 to Battalion 2 (1138 hours), that Engine 3 and Ladder 2 could handle the situation. When the driver of Engine 3 arrived at the rear of the auto parts store, the Acting Lieutenant and the fire fighter specialist were coming out the rear door. Battalion 2 now ordered Engine 1 back into service. Engine 3 driver asked if they had noticed the smoke, which was now more intense and noticeable, coming from the roof, and they stated, yes. At this point, the fire fighters from Engine 3 pulled off the first 1 3/4-inch hose. The Acting Lieutenant took the charged line and went back inside the store, returning shortly to pull a second line. While the fire fighter specialist was donning his self-contained breathing apparatus (SCBA), the Acting Lieutenant was using the second line to knock down the fire that was coming through the edge of the roof. When the fire fighter specialist donned his SCBA, he and the Acting Lieutenant entered the back door with the second charged line.

At 1140 hours, Battalion 2 was now on the fire scene and received a transmission from Engine 3 (Portable 3) to strike a second alarm. Battalion 2 also requested police assistance from dispatch to help evacuate the adjoining buildings.

At 1141 hours, dispatch ordered Engine 14 and Engine 2 to respond to the second alarm.

At 1142 hours, Engine 3 (Portable 3–inside the auto part store) requested pike poles and assistance in removing the ceiling. Meanwhile, Engine 3 at the rear of the store was calling for an Engine to lay a supply line, as he would be out of water shortly.

At 1145 hours two fire fighters from Ladder 2 positioned their unit facing the auto parts store. They walked up to the front door and observed a brisk wind (approximately 30 miles per hour) blowing through the thick black smoke in the store. They could not see any fire, but the blowing wind, and the heavy smoke made it apparent that there was a heavy fire somewhere, so they decided not to enter the building.

At 1149 hours, Portable 3, inside the auto parts store, radioed that they were in trouble and could not get out. However, due to the heavy radio traffic, Battalion 2 (positioned in front of the store) did not understand the transmission. Battalion 1, en route to the fire scene had picked up the radio transmission and radioed Battalion 2 that the transmission sounded like someone was trapped inside the building.

At 1150 hours, without warning, the fire accelerated rapidly, and the entire roof collapsed into the auto parts store.

The building was now totally engulfed in fire and conditions were changing rapidly: a fire fighter from Engine 1 noticed that the hose line leading into the rear door of the building had burned through, allowing water to flow freely; numerous explosions were heard inside the store (overheating pressurized cans); and Engine 3 had to be moved for fear of losing the Engine due to the extreme heat as the fire was being whipped over the Engine.

At 1208 hours, Battalion 2 stated he may have two fire fighters down inside the burning building. Fire suppression operations continued, using multiple streams to contain and extinguish the fire. The two fire fighters (Acting Lieutenant and fire fighter specialist) inside the building were unable to escape as the roof collapsed and died in the fire.

CAUSE OF DEATH

Preliminary cause of death was listed by the medical examiner as body burns and smoke inhalation.

RECOMMENDATIONS/DISCUSSION

Recommendation #1: Fire departments should ensure that fire command always maintains close accountability for all personnel at the fire scene. [1-4]

Discussion: Accountability for all fire fighters at a fire scene is paramount, and one of the fire commands’ most important duties. Although the Acting Lieutenant from Engine 3 had assumed command upon arrival at the incident site, informal transfer of command was assumed by Battalion 2 upon arrival. However, Battalion 2 was positioned in front of the auto part store and was not aware of the two fire fighters in the store. The driver of Engine 3 was not in a position at the rear of the store to determine the location of the Acting Lieutenant and fire fighter specialist who had entered the rear door. His line of sight was blocked by a trailer parked at the rear of the store. He assumed they had gone out the front of the store. One method of accountability is a buddy or team system, whereby, if any part of a team is not accounted for, fire command is notified immediately, signaling that a potential life-threatening problem may exist.

Recommendation #2: Fire departments should ensure at least four fire fighters be on the scene before initiating interior fire fighting operations at a working structural fire. [2,5]

Discussion: When Engine 3 arrived at the auto parts store, no fire was showing, and very little smoke was visible. However, within a few minutes, fire and smoke were visible from the rear of the store. Unaware of the involvement between the suspended ceiling and the roof, the fire fighters proceeded into the auto parts store with a charged line to knock down any visible fire from the inside. The driver of Engine 3 was busy pulling line and running the pump, and he was not in line of sight or communication with the two fire fighters inside the building. The National Fire Protection Association (NFPA) recommends that four persons (two in and two out) each with protective clothing and respiratory protection is the minimum number essential for the safety of those performing work inside a structure. The team members should be in communication with each other through visual, audible, or electronic means to coordinate all activities, and determine if emergency rescue is needed.

Recommendation #3: Fire departments should ensure that standard operating procedures and equipment are adequate and sufficient to support the volume of radio traffic at multiple-responder fire scenes. [3]

Discussion: The fire ground communications at the fire scene became ineffective at times because of all the radio traffic, dispatch messages, and noise at the fire ground. All communication at the fire scene was on channel 1, not channel 2, the tactical channel. Therefore, all communications between dispatch and all those on channel 1 were competing for air time. Battalion 2, stationed in front of the auto parts store, was not able to receive and understand the emergency transmission from Engine 3 fire fighters inside the building that they were in trouble. The standard operating procedures and communications equipment should be of sufficient quality to support the volume of communications encountered at this fire scene.

Recommendation #4: Fire departments should ensure that pre-fire planning and inspections cover all structural building materials/components.

Discussion: The strip mall was built prior to 1984 of masonry walls and steel supported roof trusses. In 1984 the auto parts store was built at the East end of the shopping mall of masonry walls and wood roof trusses. The auto parts store had wooden trusses that spanned a 50-foot width, plus had three HVAC units mounted on the top, with an estimated weight of 3000 pounds. Wooden roof trusses used in building construction should have a minimum fire resistance rating (the length of time the member can be subjected to a standard fire test without failing) of 1 hour. [6] Each structure in a multi-structure unit should be pre-fire inspected to determine interior design and the type of materials used in construction.

Recommendation #5: Municipalities should ensure that all electrical circuits are installed in accordance with the National Electrical Code, and fire departments should include electrical inspection on pre-fire planning and inspection. [7]

Discussion: An investigation in to the circumstances of this incident revealed there was no driven ground at the electrical distribution panel, and the potable water system that was being used for a ground consisted of a combination of copper piping and polymer piping. The electrical system was not properly grounded, and a short circuit was initiated by the accidental contact between the electric company truck boom and the service drop which broke the neutral conductor, producing hot connections throughout the electrical system in the store.

REFERENCES

- Morris, Gary P., Brunacini, Nick., Whaley, Wynn; Fireground Accountability: The Phoenix System, Fire Engineering, Vol. 147, No. 4, April, 1994.

- National Fire Protection Association. NFPA 1500, Standard on Fire Department Occupational Safety and Health Program, National Fire Protection Association, Qunicy, MA.

- National Fire Protection Association. NFPA 1561, Standard on Fire Department Incident Management System, National Fire Protection Association, Quincy, MA.

- National Institute for Occupational Safety and Health. Guide to Industrial Respiratory Protection, DHHS (NIOSH) Publication No. 87-116.

- 29 Code of Federal Regulations 1910.120, Hazardous waste operations and emergency response.

- Gaylord, E.H., and Gaylord, C.N.; Structural Engineering Handbook, 3ed, McGraw-Hill Publishing Company, 1990.

- National Electric Code. Article 250 – Grounding. National Fire Protection Association (NPFA), Quincy, MA. 1996