Tree Trimmer/Climber Dies After Falling 40 Feet With an Uprooted Tree Trunk--Virginia

FACE 9615

SUMMARY

On July 23, 1996, a 26-year-old male tree trimmer/climber (the victim)employed by a right-of-way utility-line clearance company was killed after he fell approximately 40 feet with an uprooted tree trunk. The victim was working with two other employees cutting and trimming a tree with three vertical tree trunks (branching out from a common area on the ground) that had been secured together with steel cables. The victim climbed and tied himself into a fork on one of the trunks, and when he cut the cable securing the trunks together, the trunk he was positioned in uprooted. The victim and tree trunk fell to the ground and the victim was crushed between the tree and another tree limb upon impact. NIOSH investigators concluded that, to prevent similar occurrences, employers should:

- ensure that employees are aware of alternate methods of detecting and safely removing hazardous trees

- employers should use all available resources to enhance the safety performance of the company

- review and expand, where applicable, the Climber’s Guide to Tree Hazards; a booklet distributed to and used by each tree trimmer/climber employee

- conduct scheduled and unscheduled safety inspections to ensure that safety procedures are being followed.

INTRODUCTION

On July 23, 1996, a 26-year-old male tree trimmer/climber (the victim) employed by a right-of-way utility-line clearance company was killed when the tree he was working in fell to the ground. On July 29, 1996, officials of the Virginia Occupational Safety and Health Administration (VAOSHA) notified the Division of Safety Research (DSR) of the death and requested technical assistance. On August 22-23, 1996, a DSR safety specialist and a safety engineer traveled to the incident site to conduct an investigation. The incident was reviewed with the division safety and training coordinator from the company and with the OSHA compliance officer assigned to the case. Photographs and a videotape taken after the incident occurred were reviewed, along with the medical examiner’s report and the company’s written safety program.

The company involved in this incident has been in business for 89 years and provides right-of-way and utility-line clearance services. The company employs 1,500 workers in 5 districts throughout the mid-Atlantic states. The company has a written safety policy, designated safety director and five safety officers, and a written safety program. Training is accomplished on-the-job, and with the use of manuals and videos. Tailgate safety sessions are held weekly by the foreman and quarterly safety meetings are held in each district. Employees are given safe work practices handbooks and tree trimmers/climbers additionally receive the Climber’s Guides to Tree Hazards at the time they are hired. The victim had worked for the employer for 12 years. This was the third fatality experienced in the company’s history, and the second in the past 5 months.

INVESTIGATION

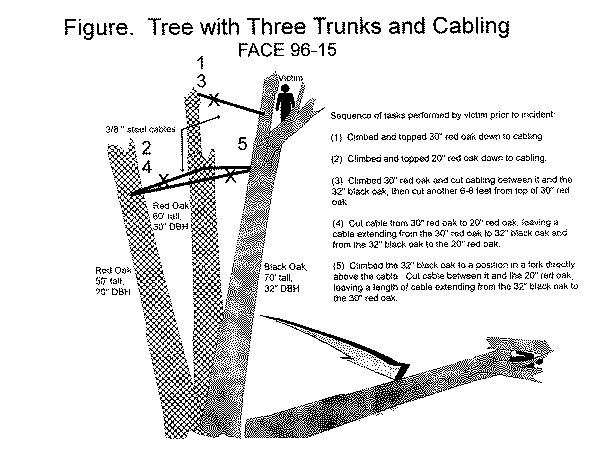

The company had been contracted to clear brush and trees from around an existing utility-line right-of-way. The victim and four co-workers (two foremen, one groundsman, and one other tree trimmer/climber) began work about 8:30 a.m. on the morning of the incident. The incident occurred in the backyard of a private residence in proximity to utility lines on a relatively flat area of land. Several trees were on the property, including a tree with three trunks. The tree had two red oak trunks (30 and 20 inches in diameter at breast height [DBH]) about 60 feet tall, and a black oak trunk (32 inches DBH) about 70 feet tall. The trunks had been secured together with 3/8-inch-diameter steel cables probably 15-20 years prior to the incident. One steel cable was strung through eye bolts which had been screwed into each of the three trunks and strung from one trunk to another, forming an incomplete triangle about 40 feet above the ground. The second cable was strung from eye bolts and connected the 32-inch tree with the 30-inch tree.

Prior to the incident, one foreman and the other tree trimmer climber proceeded to another work area to commence work as the remaining workers, including the victim, prepared to take down the tree with the three trunks. The victim and foreman evaluated the tree by looking for obvious signs of tree rot such as butt swell, algae, rotted limbs, mushrooms, or unhealthy bark. They determined the two red oak trunks were dead, but the black oak trunk was healthy. Also, they identified the two 3/8-inch steel cables securing the three trunks together. The victim then performed the following sequence of tasks prior to the incident:

- Climbed and topped the 30-inch red oak down to the cabling.

- Climbed and topped the 20-inch red oak down to the cabling.

- Climbed the 30-inch red oak and cut the cabling between it and the 32-inch black oak, then cut another 6-8 feet from the top of the 30-inch red oak.

- Cut cable from the 30-inch red oak to the 20-inch red oak, leaving a cable running from the 30-inch red oak to the 32-inch black oak and from the 32-inch black oak to the 20-inch red oak.

- Climbed the 32-inch black oak to a position in a fork directly above the cable. He used a climbing saddle, boots with spikes, and ropes to climb the trunk and secure himself in the fork of the tree. He cut the cable between it and the 20-inch red oak, leaving a length of cable remaining from the 32-inch black oak to the 30-inch red oak.

Approximately 10-15 seconds after the cable was cut the two co-workers heard a loud “pop,” and the 32-inch tree which the victim was tied into uprooted and fell to the ground. The coworkers rushed to the area where the victim was pinned between two large limbs. The co-workers checked the victim and concluded he was dead from obvious massive crushing injuries to the head and neck. The coroner arrived about 10-15 minutes later and pronounced the victim dead at the scene.

CAUSE OF DEATH

The medical examiner’s report listed the cause of death as open skull fracture with cervical fracture.

RECOMMENDATIONS/DISCUSSION

Recommendation # 1: Tree trimmers should be aware of alternate methods of detecting and safely removing hazardous trees.

Discussion: The presence of steel cables in the tree was an indication that the tree was unstable and had been cabled to prevent breakage. Other signs of concern that should be looked for are evidence of decay (trees can decay in any area from roots to crown), cracks, root damage, dead wood in the crown, peeling bark or callous formation on the bark. Although the foreman and the victim had checked the tree trunks for rot, the rotted trunk went undetected. The area at the base where the three trunks meet is often a weak point and a site of “butt rot.” If one of the vertical trunks is weak, it should be assumed that all three of the trunks are weak. A hollow sound from rapping on the tree (though this may be less reliable when at the butt of the tree) should also be considered in determining if a tree is rotted. Additionally, an instrument called an increment core is available to arborists for detecting tree rot. This is used to drill into the tree to extract a sample of the wood at the core of the tree. The wood core is visually inspected for damage. The increment core can be used only for trees which will be felled; it should not be used on healthy trees which need only to be trimmed.

Employers should be aware of alternate methods for removing trees that are too hazardous to climb and fell. Alternate methods include the use of cranes, tying in to nearby trees, or dropping the tree. Following is a method recommended by a NIOSH forester:

Do all trimming/topping of the trunks with the initial cable intact. Take off the sections above the cable. Decide where the next cut will be and insert an eye hook on each of the vertical limbs below that point. Run a wire rope through the eye hooks to form a triangle. Use a come-along or chain stretcher to tighten the wire, using caution not to over tighten the wire. This supports the trunks and affords stability so the next sections and the cable can be cut.

Recommendation #2: Employers should use all available resources to enhance the safety performance of the company.

Discussion: It is important that tree trimming companies obtain information on safety regulations and methods of ensuring safe working conditions. Attendance at training and participation in professional organizations fosters improvement of skills and awareness of new equipment and trends in tree care and safety. One source of information is the:

National Arborists’ Association, Inc., which offers videotapes on safety and a training manual titled Tailgate Safety for Tree Care Professionals. The address of the Association is The Meeting Place Mall, Route 101/P.O. Box 1094, Amherst, NH 03031-1094. The phone number is (603) 673-3311.

Recommendation #3: Employers should review and expand, where applicable, the Climber’s Guide to Tree Hazards a booklet distributed to and used by each tree trimmer/climber employee.

Discussion: Although the booklet contains valuable information regarding common hazards associated with the tree trimmers/ climbers’ profession, the section relating to support cables in trees could be expanded to include procedures to inspect and offer alternate ways to trim/fell trees with cables. Two elements that contributed to this incident were the undetected rotted trunk and the cabling securing the three trunks together. If additional consideration had been given to either circumstance, and appropriate measures taken, the incident may have been prevented.

Recommendation #4: Employers should conduct scheduled and unscheduled safety inspections to ensure that safety procedures are being followed.

Discussion: Although the company has a written safety program which includes tailgate safety sessions and quarterly district safety meetings, scheduled and unscheduled safety inspections should be conducted on a regular basis. To be effective, a safety program must be enforced at the worksite. Regular company safety inspections demonstrate to workers that the company is committed to enforcing its safety policies and procedures.

Figure.