52-Year-Old Electrical Technician Electrocuted in Indiana

FACE 86-41

Introduction

The National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR) is currently conducting the Fatal Accident Circumstances and Epidemiology (FACE) Project, which is focusing primarily upon selected electrical-related and confined space-related fatalities. The purpose of the FACE program is to identify and rank factors that influence the risk of fatal injuries for selected employees.

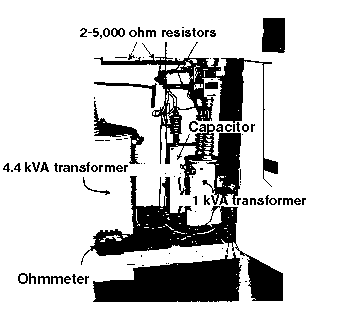

On July 21, 1986, a 52-year-old electrical technician was electrocuted while testing circuits in a metal cabinet housing power transmission and distribution equipment (see Figure).

Contacts/Activities

Officials of the Occupational Safety and Health Program for the State of Indiana notified DSR concerning this fatality and requested technical assistance. This case has been included in the FACE Project. On August 13, 1986, a DSR research team (consisting of a safety specialist and a research industrial hygienist) conducted a site visit, met with employer and union representatives, interviewed comparison workers and a surrogate for the victim, and photographed the accident site.

Overview of Employer’s Safety Program

The victim was employed by a company that designs, manufactures, and markets high voltage power transmission and distribution equipment. This facility, in operation since 1958, employs 700 people.

The safety function is managed by the industrial relations supervisor on a collateral-duty basis. A comprehensive written safety program exists at the company. Most high risk jobs have a written safe job procedure. New employees receive on-the-job training from co-workers and supervisors. The company has a Safety Policy Committee (whose membership consists of management executives), a Union Safety Committee (whose membership consists of employees), safety observers (designated employees in each department), an infirmary which is staffed by an occupational health nurse during the day shift, and a fire brigade. Each of the safety committees meet monthly.

Synopsis of Events

A small part of the company’s business is to repair power transmission and distribution equipment which is housed in metal cabinets. Having completed the repairs on electrical components within one of the metal cabinets the previous Saturday, the repair shop sent the unit to the quality assurance department for a final check. The metal cabinet (6′ wide, 5′ high, and 5′ deep) contained a one kVA transformer, a capacitor, and two 5000 ohm resistors. Electric service (110 volts, 60 Hz, 20 amp) was supplied to the one kVA transformer from a bank of receptacles located on a variable output transformer (rated 0-240 volts) used for testing. The one kVA transformer stepped up voltage to 10 kV. There were no audio or visual indicators that electricity was being supplied from the variable output transformer to the electrical components within the cabinet.

While checking out the unit, the victim determined that the rectifiers in the control circuit were shorted. Both rectifiers were replaced and the victim continued to follow the testing procedure check list. At approximately 1:30 p.m. the victim was at the point in the test where he was to measure the resistance of the two 5000 ohm resistors with an ohmmeter. Apparently he reached into the cabinet with his left hand and attempted to remove one of the resistors. When he touched the resistor his body provided a path to ground and he was electrocuted. The victim fell to the concrete floor.

A nearby co-worker saw a flash, went to the fence enclosed work area, and immediately de-energized the power. Another co-worker called the company nurse. A third co-worker and the company nurse administered CPR until the EMS arrived. The EMS began advanced cardiac life support. The victim was transported to a nearby hospital where he was pronounced dead on arrival.

Cause of Death

The coroner determined that the cause of death was due to electrocution. The victim had burns on his left forefinger and thumb (entry wound) and a burn on his right thigh (exit wound).

Recommendations/Discussion

Recommendation #1: The testing procedure and the check list for this task should be re-evaluated. All unnecessary exposure to energized equipment should be eliminated or personal protective equipment should be identified.

Discussion: The test procedure should be re-evaluated to identify any unnecessary exposure to energized equipment. Engineering controls should be used whenever possible to protect test personnel from inadvertent contact with energized equipment. One design modification that could be used to eliminate/minimize exposure to energized equipment would be the use of a dead-man control. During testing and repair, all electrical energy could be supplied to these cabinets through a dead-man control. This design would require the electrical technician to be away from the cabinet, so that he could not contact energized circuitry. Personal protective equipment should be used during those procedures that require test personnel to be in the cabinet while the equipment is energized.

Recommendation #2: Workers should follow the testing procedure check list and safe job procedure for repairing and testing a cabinet containing power transmission and distribution equipment.

Discussion: The testing procedure required the victim to de-energize the circuitry within the cabinet before removing the resistors. The victim did not de-energize the circuits. When he attempted to remove a resistor with his hand, he made contact with 10 kV.

Recommendation #3: The variable output transformer should be redesigned so that it is controlled by one ON/OFF switch.

Discussion: The variable output transformer supplied 110 volts to receptacles located on the side of the variable output transformer and supplied variable voltage (from 0-240 volts) through a rheostat to four contact points located on top of the variable output transformer. Each of the two sources had its own individual ON/OFF switch located on the top of the transformer. Even though the switch controlling the variable voltage portion of the transformer was in the OFF position, the switch controlling the receptacles was in the ON position and energy was supplied to the metal cabinet.

Recommendation #4: The design of power transmission and distribution equipment should incorporate safety considerations to protect workers who maintain, repair, and test these cabinets.

Discussion: The current design of these cabinets does not include (1) a power ON indication for the cabinet, (2) interlock of the access to the cabinet, (3) adequate insulation of the conductors inside the cabinet to safeguard against accidental contact, or (4) appropriate warning signs. Design considerations similar to the above should be incorporated into these cabinets. For instance a power ON indicator could be installed in a conspicuous location, as near as possible to the service entrance of the metal cabinet. The indicator would serve as a reminder that electrical energy is being fed into the cabinet. The victim had repaired many similar pieces of equipment previously and he was considered an experienced electrical technician. The indicator may have alerted him to the fact that the cabinet was energized.

Figure. Cabinet Containing Power Transmission and Distribution Equipment Involved in Fatality