21-Year-Old Technician Electrocuted in Indiana

FACE 86-14

Introduction:

The National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR) is currently conducting the Fatal Accident Circumstances and Epidemiology (FACE) Project, which is focusing primarily upon selected electrical-related and confined space-related fatalities. The purpose of the FACE program is to identify and rank factors that influence the risk of fatal injuries for selected employees.

On February 17, 1986, a plastic extrusion machine operator was electrocuted after he re-energized the corona treater on his machine. (This process is described in detail as part of the Synopsis of Events.)

Because FACE researchers were unavoidably delayed in responding to this incident, the evidence concerning the accident and the equipment involved were significantly altered by the time this FACE field evaluation was conducted.

Contacts/Activities:

Officials of the Occupational Safety and Health Program for the State of Indiana notified DSR concerning this fatality and requested technical assistance. This case has been included in the FACE Project. On March 18, 1986, the DSR Research Team (a safety specialist and a safety engineer) met with employer representatives, conducted a site visit, interviewed comparison workers, and photographed the accident site.

Overview of Employer’s Safety Program:

The victim had been employed for eight months by a plastic extrusion company that employs 175 workers in three plants. In 1984 and 1983 the company employed 125 and 92 workers, respectively. The company does not have a written safety policy or program. The manager of manufacturing is assigned safety responsibility on a collateral-duty basis and spends between 5%-10% of his time on these duties. The safety committee consists of employees from all three plants and its membership consists of management, supervisors, and employees. The committee meets every six weeks to inspect the facilities and discuss the hazards identified.

All new employees are given a brief orientation and are assigned to a supervisor from the production area. The supervisor provides on-the-job training. Based upon the workers compensation experience modification rate, the company has reduced work-related injury costs over the past three years and is rated slightly better than the industry as a whole.

Synopsis of Events:

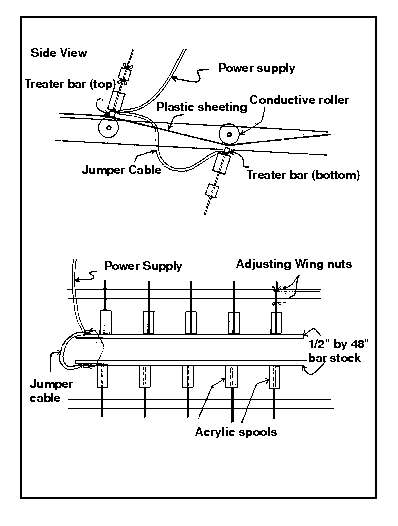

On February 16, 1986, the victim (a 21-year-old male, plastic extrusion machine operator) worked the third shift (midnight to eight a.m.). The victim’s machine was equipped to provide a corona treatment to plastic sheeting. Without this treatment it is not possible to print on the plastic sheet. The corona treatment is accomplished by charging a steel treater bar with a D.C. current. A grounded conductive roller is located near to the treater bar, so that a corona is established between the roller and the bar. The plastic sheet is passed through this corona. This treatment does not visibly change the sheet’s appearance. Two treater bars (one above and one below the sheet) are used in this process. Each treater bar has height adjustment screws so that a gap of .055 inch can be maintained between the bar and the surface being treated. (See attached figureimage icon.) The plastic treater is designed to operate at 9600 Hz. This is accomplished by converting the three-phase input to DC and inverting the DC to a high frequency sinusoidal output. This high frequency output is then fed to the high voltage transformer (10 kV) and stepped up to a level sufficient to initiate and maintain an adequate corona for the process.

The victim operated the machine without incident until 7:45 a.m. at which time the corona treater was de-energized while a maintenance man installed a bonding strap from the machine to a nearby electrical panelboard. To make the connection safely, the maintenance man de-energized the transformer that supplied power to the treater bars. However, the extrusion machine remained energized. As a result, the plastic sheet was being extruded from the machine, but the sheets were not receiving the corona treatment. After the maintenance man connected the bonding strap, the victim re-activated the transformer. While standing on a metal step on the operator’s side of the machine, the victim touched the treater wire/cable or the treater bar with his right hand and came into contact with a potential 10 kVDC, 9600 Hz source of electricity.

The victim fell to the concrete floor. Two co-workers administered CPR until the EMS arrived. He was transported to a county hospital where he was pronounced dead one hour later.

Cause of Death:

The Coroner reported that the cause of death was due to electrocution and reported entry wounds on the back of the victim’s right hand and exit wounds on his right foot.

Recommendations/Discussion:

Recommendation #1: Insulated conductors supplying power to this equipment should be enclosed in accordance with the manufacturer’s recommendations to assure proper protection for anyone working near these conductors.

Discussion: The treater wire from the transformer to the upper treater bar and the jumper from the upper treater bar to the lower treater bar were insulated, but were not enclosed in 4″ grounded aluminum conduit with acrylic supports inside the conduit (as required by the manufacturer). Additionally, the treater wire was not certified by the wire manufacturer for this application. The upper and lower treater bars should be partially enclosed to prevent personnel from coming in contact with the high voltage. A commonly used practice is to enclose the bars in a 3″ PVC tube with the ends capped. (The requirement to enclose the treater bar was addressed at the time of the FACE field evaluation.) The employer did not have an owner’s manual for the equipment and the equipment was not installed in accordance with the manufacturer’s specifications.

Recommendation #2: The company should develop and implement a comprehensive occupational safety program.

Discussion: Employee safety is a primary responsibility of employers. In order to carry out this responsibility, an employer should:

- Develop written company safety policies and procedures;

- Provide training in job procedures, including hazard identification;

- Correct recognized hazards;

- Conduct periodic inspections of the facility and evaluations of the safety program; these inspections/evaluations should be performed by qualified safety personnel;

- Encourage employees to identify and report all hazardous conditions and accidents, including close calls; action should be taken to correct those conditions determined hazardous.

Numerous safety problems were observed during the site visit. This suggests that a comprehensive safety program is needed. Field evaluators received several reports that employees were routinely “tingled” (shocked) when they contacted conductors, but management had taken no action to resolve these problems.

Recommendation #3: After making adjustments/modifications to equipment or processes, maintenance personnel should test the equipment to assure that the equipment is operating safely before placing the equipment back into service.

Discussion: Maintenance personnel apparently did not verify that the equipment was operating properly prior to placing it back in service. Although it is doubtful that the installation of the bonding strap played a major role in this fatality, testing of equipment prior to its being placed back in service is a good work practice.

Recommendation #4: Personnel should be adequately trained and equipped to install, operate, maintain, and repair plastic extrusion and corona treater equipment.

Discussion: Corona treater equipment requires the use of high voltage electricity. Maintenance personnel and machine operators require a certain level of expertise to install, maintain, repair, and operate this equipment. The manufacturer suggests that specific pieces of test equipment be available for these functions. The employer should provide test equipment and should insure that personnel are trained properly concerning the maintenance and use of this equipment.

Figure. Corona Treatment of Polyurethane Sheets