Utility Company Employee Electrocuted in California While Drilling Under a Road

FACE 85-42

Introduction

The National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR) is currently conducting the Fatal Accident Circumstances and Epidemiology (FACE) Project, which is focusing primarily upon selected electrical-related and confined space-related fatalities. By scientifically collecting data from a sample of fatal accidents, it will be possible to identify and rank factors that influence the risk of fatal injuries for selected employees.

On July 18, 1985, crewmen for a gas utility company were using an air-driven machine to drill horizontally under a road to provide new gas line service. One worker was electrocuted and a second was injured when the drill contacted a 4160 volt power line.

Contacts/Activities

Union officials notified the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR) of this fatality and requested technical assistance. This case has been included in the FACE Project. A research team (a nurse and a physician) visited the city where this fatality occurred and met with company and union representatives and OSHA officials. A meeting was held with officials from both unions representing the employees of the utility company. A separate meeting was held with company representatives (the supervisor of employee safety and a member of the industrial relations safety staff). The actual accident site was not visited because substantial changes had occurred to the area since construction had been completed. However, the drilling procedure was observed at another work site. This procedure was photographed by the NIOSH team. A meeting was held at the district OSHA office where the OSHA investigation records were reviewed and discussed with the compliance officer assigned to investigate this fatality. A closing conference was held with representatives of the union.

Overview of Employer’s Safety Program

This gas utility company has over five thousand employees who are represented by two separate unions. The company is divided into two major organizational elements: six transmission divisions maintain pipeline operations bringing natural gas to the area; thirteen distribution divisions provide service to residential and commercial consumers. The crewmen involved in this incident worked for one of the forty-seven distribution facilities (under one of the distribution divisions). A crew, consisting of a crew leader and one or two crew assistants, receive formal classroom training prior to working in the field. A crew assistant receives ten days of classroom training concerning field operations and a crew leader has approximately eight weeks of additional classroom work which includes welding and plastic fusion training. The company safety staff consists of two safety supervisors, four safety representatives, and an industrial hygienist (recently hired). There are also six facility safety engineers concerned with safety of existing facilities (meters, equipment, etc.).

All job operations are addressed by three levels of information needed to perform a specific task (i.e., job practices, job procedures, and job instructions) and are written. Job instructions are carried on the crew truck. If questions arise about job instructions, support is obtained from a supervisor at the local distribution facility, who is responsible for safety at the local distribution facility. It is the responsibility of these supervisors to see that all job instructions are followed.

Synopsis of Events

On July 18, 1985, crewmen of a gas utility company were assigned to provide new service to an apartment building that was under construction. The crew consisted of three people, since the procedure to bore underground requires a crew of this size. The crew leader had sixteen years of experience on the job and the victim had four years of experience.

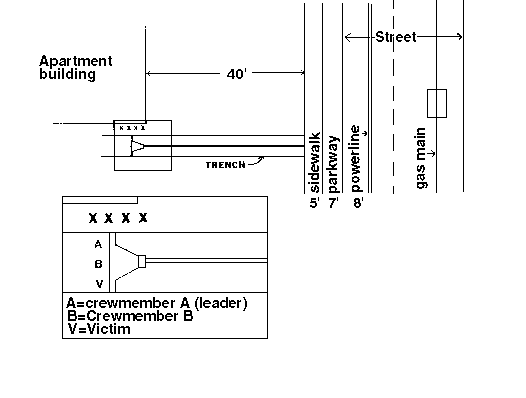

A service line was to be installed to connect an apartment building to the main (which is located under the street). See figure 1image icon. The area had been previously inspected by the crew leader. Telephone and street light electrical utilities were excavated and identified in the parkway. Power to the apartment was supplied by above ground lines. A non-profit organization that is responsible to alert utilities when excavation may affect their equipment had been notified. The local telephone company had marked their lines in response to this notification; however, the underground electric lines had not been marked by the local municipality. The municipality does not routinely mark their underground electric lines.

Partial excavation of the site had been completed by the gas company so that the procedure to bore under the street could take place. A trench had been excavated from the apartment building to the sidewalk. One hole had been dug in the parkway to expose telephone and street light service lines. Another hole had been dug in the street to expose the gas main. Although the crew had the equipment and training to electronically identify other underground metal structures, this was not done because the crew questions the reliability of the equipment currently being used.

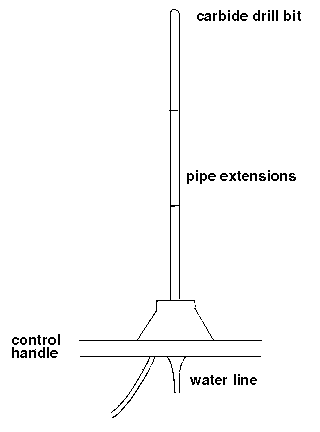

The crew was attempting to bore under the sidewalk and under the street to install a service line. The equipment used to bore this hole was an air driven, water-lubricated, low RPM drill with a carbide bit (see figure 2image icon). Pipe extensions are added as required. This equipment is usually operated by two crew members, but is occasionally handled by three when difficulty is encountered. Three attempts to bore a hole under the street were made with the fatality occurring on the third attempt. The first attempt resulted in the drill bit coming up through the street approximately two feet from the hole that exposed the gas main. The second attempt was not successful because resistance was met and the drill could not be advanced. All three crewmen were pushing on the machine during the third attempt because excessive resistance was encountered. A 4160 volt power line, encased in four inches of concrete, was contacted at approximately 2:10 p.m. resulting in one fatality and one serious injury. The third crewman felt a shock in his hands and released the equipment. The crew leader tried to release the equipment and fell to the ground unconscious. He suffered third degree burns on his hands and shoulders. The victim went into convulsions and slumped over the equipment. The victim had burn marks on both hands and the front of his right thigh and was pronounced dead at a local hospital after resuscitation efforts failed.

Excavation of the site done during the post-accident investigation revealed a four inch thick concrete conduit approximately twenty-six inches below the street surface. The concrete was chipped near the top edge (presumably from the first attempt to bore under the street) and another damaged area was noted on a lateral of the conduit (presumably from the second attempt). A hole was found on the lateral side of the conduit where the drill bit pierced the cement and came into contact with the power line. The line was located prior to excavation using the underground metal locating device present on all underground service trucks. (It should be noted that a similar incident occurred in 1983 involving a 110 volt line. No serious injuries occurred.)

Cause of Death

The medical examiner determined the cause of death to be electrocution.

Recommendations/Discussion

Recommendation #1: A thorough survey of the job site should be made prior to any excavation or drilling procedures. This should include locating all underground utilities.

Discussion: An organization exists that provides information to all service utilities that excavation is to occur which may involve their equipment. No excavation or drilling procedures should be initiated unless all utilities have marked their service lines. In addition, the underground metal locating device should be used prior to any excavation or drilling procedure to verify that a clear path exists and that all utilities have been identified. A metal locating device that is easier to operate and that more reliably differentiates underground service lines from miscellaneous metallic substances may improve its acceptability among the crew.

Recommendation #2: Drilling procedure instructions should be amended to include excavation and exposure of all service utility lines and to excavate and expose all points of resistance.

Discussion: This particular incident involved three attempts. The second attempt was unsuccessful because resistance was met. The third attempt involved three men pushing on the machine. If the point of resistance had been excavated and exposed, the electrical conduit would have been identified. The gas company has implemented this recommendation.

Recommendation #3: The company’s safety program should include hazard recognition and follow-up of previous accidents.

Discussion: As mentioned, a previous incident involving this drilling procedure and contact with a power line occurred in the past (1983). Apparently little or no investigation occurred at the time of this incident. The potential for serious injury and death should have been recognized at the time of this previous incident. Follow-up of all accidents should enable better hazard recognition so preventive measures can be implemented. The establishment of a local health and safety committee, involving both labor and management, should ensure that all accidents are adequately investigated.

Figure 1. Construction Area of Facility

Figure 2. Schematic of Bore Motor