Hispanic Carpenter Dies After Being Crushed Between the Loader Bucket of a Backhoe/Loader and a Concrete Building - North Carolina

NIOSH In-house FACE Report 2003-06

November 2, 2004

Summary

On January 6, 2003, a 25-year-old male Hispanic carpenter (the victim) died after being crushed between the loader bucket of a backhoe/loader and a concrete building. The victim was part of a three-man crew assigned to cover a window with plywood. The victim and a coworker climbed into the loader bucket of the backhoe/loader with the plywood. After the loader bucket was raised to the window, the backhoe/loader operator noticed that one of his coworkers was losing grip on the plywood. The operator, who had placed the loader bucket controls into neutral, jumped off the backhoe/loader to assist. As he jumped, the strap of his fall protection harness, worn as required by company policy, became entangled on the loader bucket control lever, moving it to the dumping position. When the bucket tilted forward, one coworker jumped off the bucket unharmed; the victim, who remained in the bucket, was pinned and crushed against the building. The backhoe operator reversed the backhoe/loader to free the victim. Emergency Medical Services (EMS) personnel arrived within 5 minutes of the 911 call and transported the victim to a local hospital emergency room where he was pronounced dead.

NIOSH investigators concluded that, to help prevent similar occurrences, employers should:

- develop, implement and enforce a written policy which requires the use of specified types of working platforms for elevated tasks

- develop, implement and enforce a written policy that prohibits employees from riding in or working from backhoe/loader buckets

- conduct a pre work meeting each day to discuss the work to be performed, potential safety hazards and safe work procedures and encourage workers to communicate with their supervisor whenever an unexpected situation occurs

- develop, implement and enforce a comprehensive training program that provides all workers with training in the proper use of personal protective equipment; and warn workers that inappropriate use of PPE could create safety hazards

- ensure that equipment operators are trained in the proper use of the equipment they are assigned to operate and ensure that an evaluation of the equipment operator’s performance in the workplace is part of the training program

- ensure that workers who are part of a multilingual workforce comprehend safety training and follow safety instructions required for their assigned tasks

- establish a policy that equipment keys are issued by a designated person only to employees authorized to operate equipment

Introduction

On January 6, 2003, a 25-year-old Hispanic carpenter (the victim) died after being crushed between the loader bucket of a backhoe/loader and a concrete building. On January 7, 2003, officials of the North Carolina Occupational Safety and Health Administration (NCOSHA) notified the National Institute for Occupational Safety and Health (NIOSH), Division of Safety Research (DSR), of the incident. On February 5, 2003, a DSR safety and occupational health team investigated the incident. The NCOSHA compliance officer assigned to the case was present throughout the investigation. The DSR team reviewed the incident with the company site superintendent, one of the vice presidents, and the two Hispanic workers who had been involved in the incident. Another worker who spoke both English and Spanish also attended the interviews as an interpreter. During an on-site visit, photographs of both the incident site and the equipment involved in the incident were taken. Police reports were also reviewed. The official cause of death was obtained from the medical examiner via telephone.

The victim’s employer was a general contractor that had been in business since March 1985. The company employed 500 full-time employees. Twenty-two employees had been working at the incident site for 16 months building a multi-unit residential complex, which was expected to be completed in July 2003. The work shift generally started at 7:30 a.m. and ended at approximately 4 p.m. daily.

The victim, an emigrant from Mexico, had worked on this construction site as a subcontractor for a few months before being hired by his present employer as a carpenter 6 months before the incident. The victim and his two coworkers, who had known each other prior to the victim’s joining the company, primarily spoke Spanish. They spoke very little English. The site superintendent in charge of this project only spoke English.

The company had a written safety program that was adapted from a major safety and health publishing company. The safety program was written in both English and Spanish. Safety meetings were held weekly and information was communicated in both English and Spanish. Topics such as fall prevention, hazard communication, excavations and trenches, and electrical power were covered in these meetings. The topic of potential hazards associated with using a backhoe/loader had not been a subject for these talks. Backhoe/loader operator training had been provided on the job by an employee who was able to read and speak both English and Spanish. The training was focused on showing employees how to operate a backhoe/loader to complete tasks. The training had not been documented, and there were no requirements for evaluation of employees’ competency after completing the training. The backhoe/loader operator in this incident, whose job title was carpenter’s helper, had operated the company’s backhoe/loader with an experienced employee on the scene 1 hour per week for about 4 weeks before the incident. He never operated a backhoe/loader independently before the day of the incident. Up until this incident, the company had not had any workplace fatalities.

Back to Top

Investigation

The scene of the incident was a newly constructed, multi-unit residential complex that included a nine-story building complex with three levels of underground parking. This particular building integrated residential, commercial and parking facilities. The project was to be completed over a 22-month period. At the time of incident, construction debris was being removed through a chute (Photo 1), which was on the east side of the building. The victim and two coworkers were assigned to cover the window (Photo 2) under the chute with plywood to avoid window damage when debris passed through the chute.

|

|

Photo 1. This photo illustrates the debris chute on the building where the incident occurred. The photo was taken 1 month following the incident: an additional structure had been built in front of the window that the victim and coworkers were attempting to cover.

|

|

|

Photo 2. This photograph of the window and the plywood at the incident scene was taken shortly after the incident

(photograph courtesy of NCOSHA). |

On the day of the incident, the workday began with a 7 a.m. safety meeting; its topic was not specifically related to the work assignment of that day. At approximately 7:30 a.m., the window crew was sent to install the window cover. When the men arrived at the site where plywood sheets were stored, they discovered that the plywood sheets were wet, making them too heavy to carry. They decided to use a backhoe/loader (Photo 3) to transport the plywood sheets. One of the men (referred to as the backhoe operator) got the key to the backhoe/loader from an employee who was temporarily assigned to keep the heavy equipment keys.

|

|

Photo 3. The backhoe/loader involved in the incident.

|

The employee normally responsible for issuing these keys was absent from work that day. The operator drove the backhoe/loader loaded with plywood sheets to the work site. The crew then screwed two plywood sheets together and cut it to the window size. The plywood could then be wedged into the window frame, requiring no nailing that may have damaged the concrete.

The window to be covered was about 4 to 5 feet above ground level. The victim and his coworkers decided to use the loader bucket (which measured approximately 7 feet wide by 4 feet high by 3 feet deep) of the backhoe/loader to reach the window. Generally, either a ladder or a boom-supported aerial platform (Photo 4) would have been used. According to the workers involved in the incident, a ladder was not used that day because the wet plywood sheets were too heavy to be lifted manually. A boom-supported aerial platform was on site, but it was not used because the equipment would have blocked a traffic lane. According to the statements of the two coworkers during the OSHA interview, the crew was unaware that traffic had been diverted so that equipment could be parked in the traffic lane.

|

|

Photo 4. This photograph is of the boom-supported aerial platform which should have been used for the task performed in the incident. This photo illustrates that the traffic lane would have had to be closed when the equipment was in use.

|

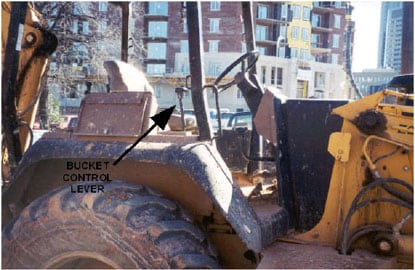

Around 9:30 a.m. after the morning break, the victim and a coworker climbed into the loader bucket of the backhoe/loader with the cut-to-size plywood. The bucket was elevated to approximately 3 feet above ground level, and then the loader bucket controls were placed in a neutral position. The victim and one coworker were standing in the bucket holding the plywood. When the backhoe operator saw one of his coworkers (not the victim) struggling to maintain a grip on the plywood, the operator attempted to get out of the backhoe/loader to help. As he exited the backhoe/loader cab to the right, the strap of his body harness, which was mandated by the company’s safety policy to be worn at all times for fall protection, was caught on the loader bucket control lever (Photo 5), located to the right of the driver’s seat, pulling it to the right. This caused the bucket to tilt forward into a dumping position. The victim’s coworker jumped out the bucket uninjured. The victim, who held onto the plywood, was pinned and crushed between the loader bucket and the concrete building. The coworker, who had jumped clear, ran to the office for help. After the backhoe operator took off his body harness to free himself, he reentered the backhoe/loader cab and backed up approximately 2 to 3 feet to free the victim. The victim dropped to the ground. The operator then exited the cab to the left and ran to assist the victim. By the time EMS and police personnel responded, approximately within 5 minutes, the victim had lost consciousness. EMS immediately transported the victim to a local hospital emergency room where he was pronounced dead.

At the time of the incident the site superintendent was working inside the building and did not witness the incident.

|

|

Photo 5. This photograph was taken from the right of the backhoe/loader.

|

The backhoe/loader used in the incident (Photo 3) was owned by the company. The site superintendent indicated that he had no knowledge that the loader bucket of the backhoe/loader had ever been used to lift or transport people prior to the incident.

When the equipment inspectors from the company and the manufacturer examined the backhoe/loader involved in the incident, they did not find any evidence of malfunction. According to the NCOSHA report, an EMI (Equipment Manufacturers Institute) booklet, written in English and used for training, was found in the backhoe/loader, but the operator’s manual from the manufacturer was not.

Back to Top

Cause of Death

The medical examiner’s report indicated that the death resulted from blunt force injuries of the chest, abdomen and pelvis.

Recommendations/Discussion

Recommendation #1: Employers should develop, implement and enforce a written policy which requires the use of specified types of working platforms for elevated tasks.

Discussion: Elevated work tasks have been associated with many occupational hazards including risk from falls.1 To help reduce this risk, equipment specifically designed for working at heights should always be used for elevated tasks. Having an enforced written policy to require the use of specified types of working platforms for elevated tasks could help eliminate or reduce risks from falls and other hazards.

Recommendation #2: Employers should develop, implement and enforce a written policy that prohibits employees from riding in or working from backhoe/loader buckets.

Discussion: The loader bucket of a backhoe/loader was used as a work surface in this incident. Although no federal standards/regulations are specifically written for backhoes/loaders, the practice of riding on any part of construction or industrial vehicles that are not intended for carrying people is expressly prohibited by OSHA2 and is recommended against by the Society of Automotive Engineers (SAE)3 and the manufacturer of the backhoe/loader. The EMI Backhoe/Loader booklet recommends against using a bucket for a work platform or personnel carrier.4

The bucket of a backhoe/loader was not designed to be used as a work platform. For example, the buckets swing, creating an unstable environment; they are not equipped with fall protection features such as a standard railing; they have a very limited work surface that may not be flat; and the workers do not have access to the operating controls, which is one of the risks that was present in this incident. It is essential that a written policy is implemented and enforced to prohibit workers from riding in or working from backhoe/loader buckets.

Recommendation #3: Employers should conduct a prework meeting each day to discuss the work to be performed, potential safety hazards and safe work procedures and encourage workers to communicate with their supervisor whenever an unexpected situation occurs.

Discussion: Because occupational hazards are widely variable by different work tasks or under different work conditions, training/retraining all workers in the recognition and avoidance of unsafe conditions can be a challenge. Recognizing and avoiding unsafe conditions also depends on employees’ working experiences. While a company’s comprehensive written safety program and its safety training program provide an overall framework for worker safety, a daily prework meeting gives workers instructions regarding the day’s scheduled work and an opportunity to discuss potential hazards that may arise and possible solutions. It may also provide effective communication channels for exchange of information related to work assignments, such as the information regarding traffic diversion in this incident. Employers should create a working environment that encourages workers to consult their supervisor whenever an unexpected situation occurs. In this fatal injury case, if the victim and his coworkers had been made aware of the traffic diversion, they might have used appropriate equipment (a long boom-supported aerial platform shown in Photo 4) that was available at the work site, and the fatal incident might have been avoided.

Recommendation #4: Employers should develop, implement and enforce a comprehensive training program that provides all workers with training in the proper use of personal protective equipment; and warn workers that inappropriate use of PPE could create safety hazards.

Discussion: Personal protective equipment (PPE) is an important means for hazard control. Employers should not only provide PPE, but they should also ensure that workers are trained to use it properly. Inappropriate use of PPE could create a safety hazard. The operator’s loose harness strap was one of the significant contributing factors for this fatal incident.

Loose clothing has been well recognized as a potential safety hazard. In its Backhoe/Loader booklet,4 the EMI warns against wearing loose-fitting clothing, flopping cuffs, or dangling neckties and scarves during operations. Loose-fitting PPE parts can be hazardous as well. It is the employer’s responsibility to ensure that all workers know how to use PPE correctly and have appropriate knowledge of PPE; and, to ensure that equipment operators wear no loosing-fitting clothing or PPE when they operate or work around the equipment.

Recommendation #5: Employers should ensure that equipment operators are trained in the proper use of the equipment they are assigned to operate and ensure that an evaluation of the equipment operator’s performance in the workplace is part of the training program.

Discussion: Equipment operator training should place emphasis on how to safely operate the machine, not just how to use the machine. To do so, it is crucial to educate operators on all recommendations and instructions in the operator’s manual from manufacturers, which should be kept in the machine at all times. The EMI booklets can be used in conjunction with the operator’s manuals from manufacturers, but the booklets should not be used alone as they are not machine specific.

The safety recommendations for safe operation of a backhoe/loader were not followed during the operation involved in this incident. For example, the recommendation from both the EMI, in its Backhoe/Loader booklet,4 and manufacturer’s operator manual, instructs operators to never jump on or off when getting on and off the machine; to always maintain a three-point contact with steps and handrails, and to face the machine. Employers should convey to workers that failure to observe all safety instructions could result in injury or death.

The backhoe operator stated during the OSHA interviews that although he had operated the backhoe/loader 1 hour per week for 4 weeks with an experienced employee on the scene before the incident, he was never evaluated for his competency in operating the backhoe/loader. Backhoe/loader operators should be trained to follow the manufacturer’s operating and service procedures given in the operator’s manuals. For help with such training, the equipment manufacturer or dealer should be contacted for obtaining manuals, instructional videos, and operator training courses. The completion of the training should be documented and operators should be evaluated for competency.

Recommendation #6: Employers should ensure that workers who are part of a multilingual workforce comprehend safety training and follow safety instructions required for their assigned tasks.

Discussion: Overcoming language and literacy barriers is crucial to providing a safe work environment for a multilingual workforce. Employers should develop and provide training for workers in a language and literacy level workers are able to comprehend. Interpreters should be available to explain to workers what they are to do when the work environment changes and decisions must be made regarding how to complete assigned tasks. Training documents that require a signature by workers should always be written in a language and at a literacy level that workers are capable of understanding.

Recommendation #7: Employers should establish a policy that equipment keys are issued by a designated person only to employees authorized to operate equipment.

Discussion: To eliminate and/or reduce machine-related injuries, a designated employee should be given responsibility for issuing equipment keys only to authorized individuals. These individuals should have completed equipment operator safety training.

Back to Top

References

- NIOSH [2000]. Worker deaths by falls: a summary of surveillance findings and investigative case reports. Cincinnati, OH: U. S. Department of Health and Human and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Pub. No. 2000-116.

- Code of Federal Regulations [2001]. 29 CFR 1926.602 (c)(1)(vii). U.S. Government Printing Office, Office of the Federal Register, Washington, D.C.

- Society of Automotive Engineers (SAE) [1997]. Handbook for On-Highway Vehicles and Off-Highway Machinery (v. 3). Warrendale, PA: Society of Automotive Engineers.

- Equipment Manufacturers Institute [1989]. Backhoe/loader. Chicago: Illinois. Form # BL 10-3.

Back to Top

Investigator Information

This investigation was conducted by ChuanFang Jin, MD, Occupational Medicine Resident at West Virginia University School of Medicine assigned to NIOSH, Division of Safety Research, Special Studies Section; and Doloris N. Higgins, Safety and Occupational Health Specialist, Fatality Assessment and Control Evaluation Team, Surveillance and Field Investigations Branch, Division of Safety Research.