Control of Health and Safety Hazards in Commercial Dry Cleaners: Chemical Exposures, Fire Hazards, and Ergonomic Risk Factors

December 1997

DHHS (NIOSH) Publication Number 97-150

DISCLAIMER: Mention of company names or products does not constitute endorsement by the Centers for Disease Control and Prevention (CDC).

Foreword

The Occupational Safety and Health Act of 1970 (Public Law 91-596) assures as far as possible every working man and woman in the Nation safe and healthful working conditions. The act charges the National Institute for Occupational Safety and Health (NIOSH) with recommending occupational safety and health standards and describing exposures that are safe for various periods of employment, including but not limited to the exposures at which no worker will suffer diminished health, functional capacity, or life expectancy as a result of his or her work experience.

This document represents the efforts of NIOSH researchers who have worked in collaboration with industry, labor, and other governmental organizations to protect the health of workers in the commercial dry cleaning industry. Dry cleaning is predominantly a small business industry with a substantial percentage of minority workers who are exposed to a wide array of hazards. The purpose of the document is to present the research findings and provide guidance to regulatory agencies and owners of dry cleaning shops regarding hazard control measures. Control technologies and methods are presented for reducing occupational exposures to perchloroethylene (PERC), as well as for controlling exposures to spotting chemicals, fire, and ergonomic hazards. It is not intended to provide total information in all areas of safety and health.

Significant attention has been paid to the effects of perchloroethylene on the environment while the effects of perchloroethylene on workers have often been overshadowed. Health effects associated with exposure to perchloroethylene include depression of the central nervous system; damage to the liver and kidneys; and impaired memory, confusion, and dizziness. There is increasing evidence of human carcinogenicity. The uncontrolled use of PERC has the potential to cause widespread harm to the health of the workers, the people living near dry cleaning shops, the general public, and the global environment.

This document is a positive contribution to worker health and safety. It is an essential reference on health and safety in the dry cleaning industry, which I strongly recommend to all concerned. It is my hope that this document will assist in providing a safe and healthful working environment by describing the most effective control technologies and procedures.

Linda Rosenstock, M.D., M.P.H.

Director, National Institute for

Occupational Safety and Health

Centers for Disease Control and Prevention

Abstract

This report investigates control methods and technologies used in the dry cleaning industry for reducing occupational exposures to tetrachloroethylene, also known as “perchloroethylene” (PERC). It also examines dry cleaning machines that use petroleum-based solvents. It addresses methods for controlling exposures to spotting chemicals, fire, and ergonomic hazards in commercial dry cleaning shops. Data were gathered during ten field surveys at dry cleaning shops across the U.S. and through a World Health Organization (WHO) fellowship in Europe.

The study by the National Institute for Occupational Safety and Health (NIOSH) looked at various categories of dry cleaning equipment, such as transfer and dry-to-dry, vented and unvented, and modern machines equipped with various vapor recovery devices. The evaluated shops maintained full-shift, time-weighted average (TWA) exposures to PERC below 25 ppm; however, peak exposures during machine loading and unloading were frequently near 2,000 ppm. Most operator exposures could have been further reduced during machine loading and unloading by additional control measures: the use of another cleaning media, such as petroleum-based solvents or water; the isolation of the dry cleaning process through “satellite shops”; a switch to state-of-the-art dry cleaning machines equipped with both refrigerated condensers and carbon absorbers; and more effective use of local and general ventilation.

Inhalation of spotting chemicals was not a significant hazard; however, isolation of this process would avoid unnecessary exposure to other workers. A number of recommendations are given to further reduce spotting chemical exposures. Ergonomic hazards usually involve repetitive motions and awkward postures. In dry cleaning, these problems primarily occur at the pressing stations and can be controlled. Redesigned, adjustable workstations for pressing will decrease the awkward postures and excessive reaching. Frequent breaks and worker rotation will reduce worker repetition.

Fire hazards can be reduced by a two-pronged approach. The greatest risk of fire and explosion in dry cleaning shops comes from petroleum-based solvents used in some dry cleaning machines. First, new petroleum-based solvents and machines, both of which are inherently safer than those traditionally utilized, are currently available and could serve as an alternative to PERC in some U.S. shops. Second, all shops should comply with appropriate National Fire Protection Association/Building Officials & Code Administration (NFPA)/(BOCA) codes to reduce the risk of fire not only in the dry cleaning area but also throughout the entire shop.

Preface

Under the authority of the Occupational Safety and Health Act of 1970 (Public Law 91-596), the National Institute for Occupational Safety and Health (NIOSH) conducts research to prevent occupational safety and health problems through the application of control technology in the workplace. The goal of this program is to assist in preventing hazardous exposures to workers and to document successful approaches and control measures.

This report evaluates control methods and systems for reducing perchloroethylene (PERC) exposures in commercial dry cleaning shops throughout the United States. During ten field surveys, NIOSH researchers inspected various categories of dry cleaning equipment, such as transfer and dry-to-dry, vented and unvented, and modern machines equipped with various vapor recovery devices. This study also addressed control of health and safety hazards related to petroleum-based dry cleaning solvents, control of exposure to spotting chemicals, and control of ergonomic risk factors.

Additionally, NIOSH researchers received a World Health Organization (WHO) fellowship to study methods and controls to reduce occupational exposure to and environmental emissions of PERC in Europe. This study involved gathering information concerning dry cleaning regulations, equipment, exposure levels, work practices, and alternatives to PERC in Europe. Important research into new technologies for reducing emissions and exposure to PERC has been conducted in Europe. These technologies include improved design and engineering controls for PERC dry cleaning machines and alternative technologies, such as cleaning with petroleum-based solvents or aqueous-based cleaning methods. The European visit enabled NIOSH researchers to learn about differences in the dry cleaning processes between the U.S. and Europe. Findings from this fellowship are also included in this report.

Information gathered during the study was supplemented by a literature review. This report provides a reference for anyone interested in protecting dry cleaning workers from exposures to PERC, spotting chemicals, ergonomic risk factors, and fire hazards. Individual in-depth and walk-through survey reports, which include more detailed information on specific characteristics of each dry cleaning shop and control systems studied, are available from the National Technical Information Service, Port Royal Road, Springfield, Virginia 22161.

Acknowledgements

Manuscript Authored by: Gary S. Earnest, M.S., P.E., C.S.P.

Amy Beasley Spencer

Stephen S. Smith, M.S.

William A. Heitbrink, Ph.D., C.I.H.

Ronald L. Mickelsen, M.S., P.E.

James D. McGlothlin, M.P.H., Ph.D, C.P.E.

Lynda M. Ewers, Ph.D.

Manuscript Prepared by:

Bernice L. Clark Robin F. Smith

Manuscript Edited by: Anne L. Votaw

Cover Prepared by: Anne M. Stirnkorb

Survey and Technical Assistance by:

Jim P. Agee

Paul A. Jensen, Ph.D., P.E., C.I.H.

Phillip A. Froehlich, M.S.

James H. Jones

Michael G. Gressel, M.S., C.S.P.

Ronald J. Kovein

Ronald M. Hall

Dennis M. O’Brien, Ph.D., P.E., C.I.H.

The authors would like to thank the following individuals and organizations for providing input to the study protocol: International Fabricare Institute, Fabritec International, Dryclean U.S.A., Boewe Passat Corporation, Union of Needle Trades Industrial and Textile Employees.

The authors would like to thank the following individuals and organizations for providing input and general assistance throughout the study: Boewe Passat Corporation, MultiTEX Corporation, Realstar Corporation, Union Corporation, Hohenstein Institute, Kruessler Corporation, The World Health Organization, U.S. Environmental Protection Agency, Michigan Department of Public Health.

The authors would like to express a special thanks to Mr. Max Zimmerman.

Introduction

Historically, dry cleaning was performed by hand, using petroleum-based solvents that had dangerously low flash points.1 In fact, dry cleaning is believed to have originated in France in 1825 when a worker in a dye and cleaning factory spilled lamp oil, a flammable petroleum-based solvent, on a soiled tablecloth.1 When the tablecloth dried, the spots were gone. The dry cleaning industry first used turpentine and kerosene before moving to benzene and gasoline. All of these solvents had one major disadvantage: they were flammable and caused fires and explosions.2

Over time, better petroleum-based solvents were introduced, having higher flash points. In 1928, W.J. Stoddard, president of the U.S. National Institute of Dry cleaning (now the International Fabricare Institute), introduced Stoddard Solvent, a nearly odorless, petroleum-based solvent, which gained widespread acceptance in the industry.1 Stoddard Solvent™, having a flashpoint of approximately 49°C (120°F), reduced the risk of fire and explosion, but did not eliminate it. Petroleum-based solvents eventually were restricted in urban areas because of their inherent fire hazard.

Near the turn of the century, chemists learned to synthesize chlorinated hydrocarbons and produce them in large quantities. Many of these non flammable solvents came into use for dry cleaning. Early on, carbon tetrachloride was the favorite chlorinated hydrocarbon for dry cleaning; but because of its toxicity and aggressiveness to metals, textiles, and dyes, it was gradually replaced in the 1940s and 1950s by trichloroethylene and tetrachloroethylene.2 Tetrachloroethylene is also commonly known as “perchloroethylene” (PERC).

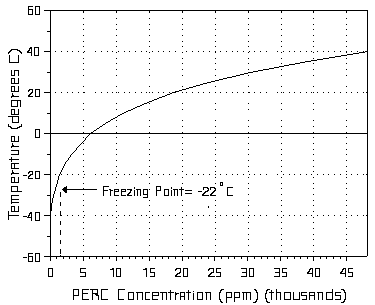

In the 1960s, CFC 113, a chlorofluorocarbon solvent, was used in dry cleaning, but never reached a significant market share. Because of its potential to deplete ozone and cause global warming, it is now banned in the U.S. and in most other countries under the Montreal Protocol. Today, approximately 90% of U.S. dry cleaners use PERC in their machines.3 PERC (C2Cl4) is a colorless, clear, heavy liquid with an ethereal odor. The odor threshold is approximately 30parts per million (ppm).4 However, because significant adverse health effects have been discovered, many countries have imposed stringent regulations for the control of PERC exposures and emissions.

The Need For Controls

Background

In the late 1970s and early 1980s, the National Institute for Occupational Safety and Health (NIOSH) sponsored an engineering control technology study in the dry cleaning industry.5 Among other health hazards, this evaluation found high exposures to the dry cleaning solvent PERC. In 1988, the Occupational Safety and Health Administration (OSHA) Director of Federal-State Operations conducted a nationwide query of the OSHA State Consultation Programs to assess which small businesses were considered to be “high risk.” The dry cleaning industry was the second most mentioned small business, preceded only by autobody repair shops.6 In 1993, NIOSH researchers conducted a preliminary hazard analysis and based upon that analysis decided to evaluate control of PERC exposures, spotting chemical exposures, ergonomic risk factors, and fire hazards.

Significant changes involving equipment, processes, and work practices have occurred within the dry cleaning industry since the earlier NIOSH study. These changes include alternative solvents and cleaning methods; a shift away from older dry cleaning machines that require manual transfer of solvent-laden garments between washer and dryer to modern, closed-loop machines; and innovations in vapor recovery equipment and other technologies to reduce occupational exposures and environmental emissions. Many of these changes have been initiated by new epidemiologic, toxicologic, and environmental data for the primary solvent PERC. Nonetheless, many of the exposure problems identified during studies in the late 1970s and early 1980s still exist in the U.S. because traditional dry cleaning machines are still being used. Many of the modern controls that have been developed are cost prohibitive for small shops, and some work practices are inadequate.

Profile of the U.S. Dry Cleaning Workforce

The Business America on Disc® CD-ROM7 file includes 48,087 dry cleaners in the U.S. The distribution by number of employees is shown in Table 1. If the number of employees/shop is a reliable estimate, between 150,000 and 365,000 individuals work in dry cleaning shops. Seventy percent (33,853) of shops employ one to four workers. Unlike the OSHA list of employees, which does not include non salaried owners, the Business America definition includes owners on site as employees since many of these firms are family operated. The U.S. Environmental Protection Agency (EPA) recently estimated that there were 30,000 commercial dry cleaning shops and approximately 244,000 employees. The National Occupational Exposure Survey8 (NOES) estimated that in 1982-83 there were over one-half million dry cleaning shop employees in more than 40,000 plants potentially exposed to PERC.

Table 1: Quantity of U.S. Dry Cleaners and Number of Employees

| Number of Employees | Number of Shops | Percentage of Total Shops | Minimum Total Employees | Maximum Total Employees |

|---|---|---|---|---|

| 1-4 | 33,853 | 70 | 33,853 | 135,412 |

| 5-9 | 8,252 | 17 | 41,260 | 74,268 |

| 10-19 | 3,482 | 7 | 34,820 | 66,158 |

| 20-49 | 1,095 | 2 | 21,900 | 53,655 |

| 50-99 | 175 | 0.3 | 8,750 | 17,325 |

| 100-249 | 62 | 0.1 | 6,200 | 15,438 |

| 250-499 | 6 | 0.01 | 1,500 | 2,994 |

| 500-999 | 1 | 0.01 | 500 | 999 |

| UNKNOWN | 1,161 | 2 | 1,161 | 1,161 |

| TOTAL | 48,087 | 10 | 149,944 | 367,410 |

Potential Hazards

Perchloroethylene (PERC)

In the U.S. PERC is the most commonly used dry cleaning solvent and is also occasionally used as a spotting agent. PERC can enter the human body through both respiratory and dermal exposure. Although nonflammable, if PERC is heated sufficiently, thermal decomposition will result in the formation of hydrogen chloride and phosgene gases. Symptoms associated with respiratory exposure include the following: depression of the central nervous system; damage to the liver and kidneys; impaired memory; confusion; dizziness; headache; drowsiness; and eye, nose, and throat irritation. Repeated dermal exposure may result in dry, scaly, and fissured dermatitis.9

Link Between PERC Exposure and Cancer.—The possible link between PERC exposure and cancer was first suspected through studies conducted by the National Cancer Institute (1977) and the National Toxicology Program (1986). A 1987 EPA study of PERC showed that, in addition to the numerous adverse health effects already known and outlined above, there was evidence of carcinogenicity. In December 1991, the EPA began regulating PERC as a hazardous air pollutant under Section 112 of the Clean Air Act.10 Other studies, including one at NIOSH, showed an elevated risk of urinary tract,11-13 esophageal,14 and pancreatic cancer15,16 among individuals who worked in dry cleaning establishments; however, since most of these studies involved exposures to various solvents in addition to PERC, a conclusive link between PERC exposure and cancer could not be made.

Although PERC has been a known animal carcinogen since the early 1990s,17 the International Agency for Research on Cancer (IARC) did not find adequate evidence to classify the solvent as a possible human carcinogen until recently.18 In 1995 the IARC classified PERC in group 2A, meaning that it is probably carcinogenic to humans. IARC also has recently classified dry cleaning in group 2B, meaning that it is possibly carcinogenic to humans. Cancer mortality research is continuing at NIOSH and other research organizations.

PERC Evaluation Criteria.—The current OSHA permissible exposure limit (PEL) for PERC is 100ppm, as an 8-hour time-weighted average (TWA). The acceptable ceiling concentration is 200 ppm for five minutes in any three-hour period, not to exceed a maximum peak of 300 ppm.19 OSHA had lowered the PEL to 25 ppm in 1989 under the Air Contaminants Standard.20 In July 1992, the 11th Circuit Court of Appeals vacated this standard. OSHA is currently enforcing the 100 ppm standard; however, some states operating their own OSHA-approved job safety and health programs continue to enforce the lower limits of 25 ppm. OSHA continues to encourage employers to follow the 25ppm limit.21 NIOSH considers PERC to be a potential occupational carcinogen.22 The American Conference of Governmental Industrial Hygienists (ACGIH) threshold limit value (TLV®) for PERC is 25 ppm.23

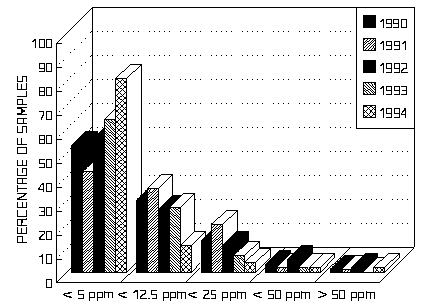

Current Exposures.—OSHA Integrated Management Information System (IMIS) data from 1984-1988 indicated that approximately 20% of exposures measured in U.S. dry cleaning shops exceeded 100 ppm for PERC.24 The more recent and comprehensive data gathered by the International Fabricare Institute’s (IFI) vapor monitoring service, using passive monitoring badges, reported a lower percentage of shops exceeding 100 ppm TWA. A summary of the IFI data is shown in Table 2.

Table 2: Passive Air Monitoring Results Collected by International Fabricare Institute

| Before 1/1/87 | 1/1/87-9/30/89 | After 10/1/89 | |

|---|---|---|---|

| TRANSFER (AVG TWA PPM) |

55.3 ppm | 46.4 ppm | 42 ppm |

| %>25 ppm | 76.2% | 59.9% | 56.8% |

| %>100 ppm | 7.7% | 5.6% | 7.0% |

| DRY-TO-DRY*** (AVG TWA PPM) |

20.5 ppm | 16.1 ppm | 17.2 ppm 16.9 ppm* 16.7 ppm** |

| %>25 ppm | 24.3% | 18.5% | 18.6%* 17.2%** |

| %>100 ppm | 1.0%> | 0.8% | 1.3%* 0.8%** |

*Denotes dry-to-dry refrigerated with small vent to purge cylinder at end of dry cycle.

**Denotes dry-to-dry refrigerated with no vent.

***Denotes standard dry-to-dry with water-cooled condenser and vent at end of dry cycle.

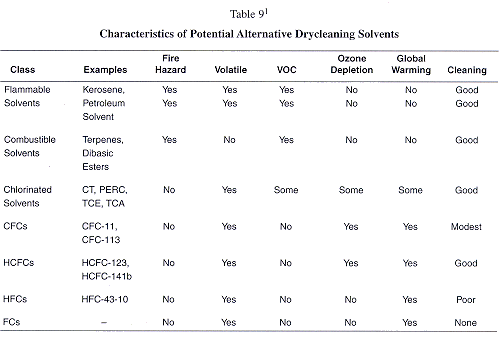

Solvent Alternatives to PERC

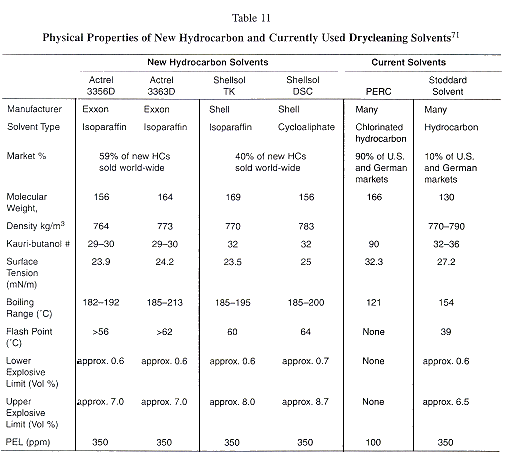

Alternative dry cleaning solvents are available, which can be effectively substituted for PERC. All petroleum-based, dry cleaning solvents are aliphatic hydrocarbons having a carbon chain of eight to twelve carbons. Hydrocarbon solvents are usually produced through fractional distillation of crude oil to produce various cuts, such as gasoline, naphtha, Stoddard solvents, mineral spirits, and kerosene. There are inherent properties that all petroleum-based dry cleaning solvents possess. These properties include flammability, solvent power, volatility, odor, and toxicity.25

Petroleum-based solvents have a much lower Kauri-Butanol (KB) value than PERC. The KB value is a relative index of solvent power. On this scale, benzene is equal to 100, and all other solvents are compared to it. Higher KB values imply better removal of oil and grease stains.26 Linear paraffins generally have relatively low KB values while aromatics generally have high KB values.

Volatility refers to the propensity of a liquid to vaporize and is quantitatively expressed as vapor pressure. The evaporation rates for Stoddard solvents are between three and six times higher than the reference solvent, n-butyl acetate. Newer petroleum-based solvents have rates as low as 10% of the reference solvent. Because petroleum-based, dry cleaning solvents generally have a lower vapor pressure than PERC, the drying process takes longer for garments cleaned with these solvents than those with PERC.

Petroleum-based solvents have a distinctive odor. Linear and branched hydrocarbons have relatively low odors while naphthenes and aromatics have strong and usually objectionable odors. Petroleum-based solvents also provide a better living condition for the growth of bacteria when water is present. The products of metabolism can cause very unpleasant odors, which can be retained by the garments. Because of this, distillation is very important, as well as antibacterial additives in the solvent.27 Petroleum solvents are toxic, but they are generally thought to be less toxic than PERC. Because the vapor pressures are lower than PERC, exposures from inhalation will generally be lower.

Health Effects of Petroleum-Based Dry Cleaning Solvents.—Aliphatic hydrocarbons are asphyxiants and central nervous system depressants. Aliphatic hydrocarbons have different toxicological properties, often based upon the length of their carbon chains. Most will cause irritation of the skin and mucous membranes of the upper respiratory tract. Repeated and prolonged exposure may cause dermatitis. Aspiration of liquid aliphatic hydrocarbons may cause diffuse chemical pneumonitis, pulmonary edema, and hemorrhage. Contamination of aliphatic hydrocarbons by benzene will significantly increase the hazard.

The most common petroleum-based dry cleaning solvents in the U.S. are Stoddard solvents and mineral spirits. Sufficient quantities of either of these solvents can cause central nervous system depression. Symptoms include inebriation followed by headache and nausea. In severe cases, dizziness, convulsions, and unconsciousness occasionally result. New petroleum-based solvents have recently been developed; however, there is a lack of health effects data for these new solvents.

Evaluation Criteria for Mineral Spirits.—Some shops use mineral spirits in their dry cleaning machine. The current OSHA PEL for mineral spirits is 500ppm, 8-hour TWA. There is no 15-minute short-term exposure limit or peak exposure limit. The NIOSH recommended exposure limit for mineral spirits is 350 mg/m3 or approximately 66 ppm. The American Conference of Governmental Industrial Hygienists (ACGIH) threshold limit value (TLV®) for mineral spirits is 100 ppm.28

Exposure to Spotting Chemicals

The chemicals commonly used in the U.S. to treat stains through pre-spotting and post-spotting are trichloroethylene; various ketones, especially methyl isobutyl ketone; petroleum naphtha; and hydrofluoric acid. Individuals who perform the spotting process could be exposed to many of these toxic chemicals through skin or eye contact and inhalation of vapors. However, the primary hazard posed by the majority of the chemicals is skin damage, resulting from chronic or acute exposure, or injury to the eyes. Although chemicals that readily vaporize and have a high toxicity can pose an inhalation risk, previous studies have shown that inhalation exposures are minimized because of the limited quantities of chemicals and the intermittent nature and short duration of the spotting task.5 Commonly, PERC exposures during spotting are many times lower than OSHA standards, as are other spotting chemical exposures, which are often below detection limits.29

Trichloroethylene is a colorless, nonflammable, noncorrosive liquid, having a “sweet odor” that is characteristic of some other chlorinated hydrocarbons. Exposure to trichloroethylene vapor can cause irritation of the eyes, nose, and throat. Prolonged skin contact with liquid may cause dermatitis. Acute exposure depresses the central nervous system and may cause headache, dizziness, vertigo, tremors, and nausea, or vomiting. In extreme cases, unconsciousness and death have been reported. Trichloroethylene addiction and peripheral neuropathy have been reported.9

The ketone family includes acetone, diacetone, methyl ethyl ketone, methyl n-propyl ketone, and methyl isobutyl ketone. Methyl isobutyl ketone is the one ketone that is primarily used in paint, oil, and grease removers. The route of entry for ketones is inhalation of vapors or percutaneous absorption. These solvents produce dry, scaly, and fissured dermatitis after repeated exposure. High vapor concentrations may irritate the conjunctiva and mucous membranes of the nose and throat, producing eye and throat symptoms. High concentrations can produce narcosis with symptoms of headache, nausea, lightheadedness, vomiting, dizziness, incoordination, and unconsciousness.9

Petroleum naphtha is an organic solvent used to dissolve or soften oils, greases, paints, and varnishes. Route of entry for this chemical is inhalation of vapors or percutaneous absorption. Naphthas are irritating to the skin, the conjunctiva, and the mucous membranes of the upper respiratory tract. Skin “chafing” and photosensitivity may develop after repeated contact with the liquid. If confined against skin by clothing, the naphthas may cause skin burns. Sufficient quantities cause central nervous system depression, and symptoms include inebriation, headache, and nausea.9

Dilute hydrofluoric acid poses a greater risk than the other spotting chemicals of acute dermal exposure; however, many of these chemicals can cause occupational dermatitis from chronic exposure to the skin. Hydrogen fluoride and its aqueous solution, hydrofluoric acid, are primary irritants of skin, eyes, mucous membranes, and lungs. Thermal or chemical burns may result from contact. Chemical burns cause deep tissue destruction and may not become symptomatic until several hours after contact, depending on the concentration. Nosebleeds and sinus trouble may develop following chronic exposure to low levels of fluoride in air.9

Evaluation Criteria for Spotting Chemicals.—The following criteria for spotting chemicals applies to chemicals for which air sampling was performed. Trichloroethylene has a PEL of 100 ppm as an 8-hour TWA, and a short-term exposure limit (STEL) of 200 pm;19 The NIOSH recommended exposure limit (REL) is 25 ppm, as an 8-hour TWA.20 For 2-butoxyethanol, the OSHA PEL is 50 ppm27 and the NIOSH REL is 5ppm.20 For hexylene glycol, NIOSH recommends a ceiling of 25 ppm.20 For methyl isobutyl ketone (MIBK), the OSHA PEL is 50 ppm, and the STEL is 75ppm.27 For n-butyl acetate, both NIOSH and OSHA have a PEL/REL of 150 ppm, and the STEL is 200 ppm.20,27

Combined Exposures.—The combined exposures of the dry cleaning solvent PERC with various spotting chemicals is a concern. The ACGIH TLV® value for PERC is 50 ppm. Because PERC and other dry cleaning/spotting solvents have some similar health effects, the additive effect of exposure must be computed as a combined exposure (CE).

Ergonomic Risk Factors

Ergonomics is the study of human abilities and characteristics that affect the design of equipment, systems, and jobs. Its aims are to improve efficiency, safety, and well being. As such, ergonomics can be applied to relieve and prevent work-related injury or illness to the musculoskeletal system of the worker. Ergonomic risk factors can include excessive manual force, repeated and sustained exertions, temperature extremes, vibration, and awkward postures resulting from inappropriately designed workstations, equipment, and work methods. Other factors are excessive work rates and duration, external pacing of work, shift work, imbalanced work to rest ratios, and restriction of worker body movement. Work-related musculoskeletal disorders can result in damage to tendons, tendon sheaths, muscles, nerves, and ligaments of the area affected.30,31

Highly repetitive tasks may consist of rapid and frequent high velocity muscle contractions. Such tasks cause the muscles to develop less tension than when contracting slowly and thereby require more muscle effort and recovery than less repetitive tasks.32 Insufficient recovery time can contribute to the incident rate of cumulative trauma disorders and can compound the musculoskeletal symptoms from repetitive tasks. In one study that did not involve dry cleaning workers, the prevalence of tenosynovitis and humeral tendinitis was significantly higher for workers engaged in machine-paced repetitive assembly work than for workers with variable tasks. Repetitive motions of the hands for some workers reached up to 25,000 cycles per workday.33

Awkward or sustained postures can pose a risk of biomechanical stress to the body, especially the joints of the upper extremities and surrounding soft tissue. Several shoulder ailments, such as thoracic outlet syndrome, have been associated with workers repeatedly reaching above shoulder level.34 Reaching above shoulder level is an activity that frequently occurs in dry cleaning shops during pressing and hanging of garments. In addition, work postures involving elevated arms could accelerate tendon degeneration by increasing the friction of tendons.35 This increased friction could be related to a decreased amount of synovial fluid acting as a lubricant.

Ergonomic Risk Factors in Dry Cleaning.—Ergonomic risk factors in the dry cleaning industry primarily occur among workers performing pressing operations that are dynamic and repetitive tasks, requiring reaching, precision gripping, and maintenance of awkward postures. These awkward postures are also present during material handling when heavy lifting may occur. In addition, pressers spend much of the day standing, which adds a potential risk for the lower limbs. Studies have shown that muscles subjected to static work require more than 12 times longer than the original muscle-contraction duration for complete recovery from fatigue.36 Information gathered by NIOSH researchers has shown a high incidence of back pain among laundry and dry cleaning workers.37

Ergonomic Criteria.—Ergonomic risk factors related to garment pressing are evaluated through time study and evaluation of workstation design and anthropometry. High repetition/insufficient recovery time, awkward postures, and other risk factors all contribute to cumulative trauma disorders.27 Repetitiveness and recovery time are evaluated according to cycle time. Low repetition jobs are categorized as such if the cycle time exceeded 30 seconds or less than half the cycle time involved to perform the same kind of task. High repetition jobs are those with cycle times less than 30 seconds or over half the cycle devoted to similar tasks.38 Awkward and sustained postures are examined with respect to guidelines found in the current literature.

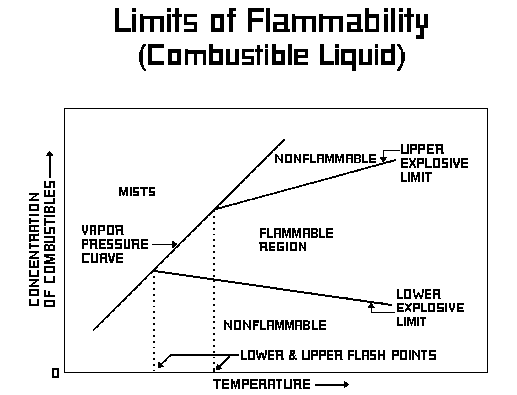

Fire Hazards

Dry cleaning with petroleum-based solvents differs significantly from dry cleaning with PERC. The difference goes beyond the fact that the petroleum-based solvents are flammable and PERC is not. However, when the health and safety hazards of petroleum-based solvents are considered, flammability is the most important property.

Flammability of Petroleum-Based Solvents.—Approximately 10% of dry cleaning shops in the U.S. use traditional, petroleum-based solvents, such as Stoddard Solvent/mineral spirits. All of these solvents are flammable or combustible liquids. Mineral spirits is a class II, combustible liquid with a flash point of 49°C (120°F). Its lower explosive limit is 0.7% or 7,000 ppm.

Exposure to the products of combustion presents numerous hazards to humans. Most prominent among these are effects from heat, impaired vision because of smoke density or eye irritation, narcosis from inhalation of asphyxiants, and irritation of the upper or lower respiratory tracts. These effects often occur simultaneously during a fire and can contribute to physical incapacitation, loss of motor coordination, faulty judgment, disorientation, restricted vision, and panic. Smoke and gases are responsible for approximately 70% of deaths during a fire.39

Carbon monoxide is generally the most abundant toxic gas produced during a fire. Carbon monoxide is produced in an accidental fire when some of the carbon present in organic materials is incompletely oxidized. Because of the large number of textiles present in dry cleaning shops, the production of hydrogen cyanide gas is another cause for concern during a fire. Hydrogen cyanide is produced from burning materials that contain nitrogen. Nitrogen is present in natural and synthetic materials, such as wool, silk, acrylonitrile polymers, and nylons. Hydrogen cyanide is a rapidly acting toxicant, which is approximately 20 times more toxic than carbon monoxide.27

Fire Codes.—The fire laws of the state, county, fire district, or community delegate general responsibility and authority to the fire officials involved in fire prevention activities. Many large cities have adopted some regulations from codes written by national technical organizations, such as the National Fire Protection Association (NFPA) or the Building Officials and Code Administrators (BOCA). Codes affecting dry cleaners that are commonly adopted are:

- NFPA 30—Flammable and Combustible Liquids Code,

- NFPA 32—Standard for Dry cleaning Plants,

- NFPA 101—The Life Safety Code,

- BOCA Basic Fire Prevention Code

Some older, dry cleaning shops are not required to comply with codes that were passed after that shop began operation. This process is known as “grandfathering.” However, compliance with current codes should reduce the risk of a fire and the associated property damage, injury, or death. Compliance may also reduce property insurance premiums. According to NFPA 101, dry cleaning plants are classified as industrial occupancies. According to NFPA 101 and the BOCA code for dry cleaning plants, those facilities having greater than 60 gallons of combustible liquid present are considered a high hazard area.

The Study

Research Objectives

NIOSH began the present study of the dry cleaning industry as a re-evaluation of the 1980 NIOSH Report. Investigators wanted to determine which of the previous engineering control recommendations were still valid, in addition to providing drycleaners with current recommendations for practical control measures. The focus of this study was to determine the best controls for PERC exposure; however, other health and safety hazards in the industry were evaluated on a more limited basis.

NIOSH researchers prepared a preliminary hazard analysis (PHA) for the dry cleaning industry. The PHA was based upon previous industry studies and walk-through surveys. For this PHA, a hazard was defined as an activity or condition that posed a threat of loss. During this analysis, the hazards listed below were identified:

- p inhalation of PERC and other solvent vapors

- p ergonomic risk factors

- p exposure to hazardous chemicals used in the spotting process

- p fire hazards

- p direct (dermal) exposure to PERC

- p thermal burns

- p heat stress

- p mechanical hazards

- p electrical hazards

- p slips/ trips/ falls

These hazards are listed from top to bottom in decreasing order of risk. The level of risk was based upon two factors:

- likelihood of occurrence

- severity of consequence

Each risk ranking is of a qualitative nature based upon the professional judgment of the authors. Because of limited resources, the authors concentrated on the following health and safety hazards in the dry cleaning industry:

- p inhalation of PERC and other solvent vapors

- p ergonomic risk factors

- p exposure to hazardous chemicals used in the spotting process

- p fire hazards

The study objective was met by evaluating controls for the various hazards and documenting results in NIOSH reports as shown in Table 3.40-49

Table 3: Hazards Studies in Plant Survey Reports

| ECTB Report # |

PERC Dry-to-Dry |

PERC Transfer |

Petroleum | Spotting Agents |

Ergonomics | Fire Safety |

|---|---|---|---|---|---|---|

| 201-11a | X | X | ||||

| 201-12a | X | |||||

| 201-13a | X | |||||

| 201-13b | X | |||||

| 201-14a | X | |||||

| 201-15a | X | |||||

| 201-16a | X | X | ||||

| 201-17a | X | |||||

| 201-18a | X | X | X | |||

| 201-19a | X | X |

Study Design

Ten dry cleaning shops were visited during walk-through and in-depth surveys between August 1993 and January 1995. Following literature searches and reviews of previous NIOSH research reports, NIOSH investigators conducted four walk-through surveys to observe a variety of dry cleaning operations. Photographs were taken during these initial surveys, as well as limited air sampling and ventilation measurements.

Results of the walk-through surveys helped determine specific businesses of interest for the six in-depth surveys. NIOSH engineers, industrial hygienists, and ergonomists surveyed each site, evaluating equipment, controls, and potential hazards (exposures to PERC and spotting chemicals, ergonomic risk factors, and fire hazards). Air sampling, video-exposure monitoring, ventilation system measurements, and process and workplace observations were performed. These data were evaluated to determine the effectiveness of each control system. Plant reports were prepared, which presented the data and results of the analysis, conclusions, and recommendations. These plant reports have served as the basis for the findings outlined in this report, as has information gathered during a World Health Organization (WHO) fellowship to study dry cleaning in Europe.

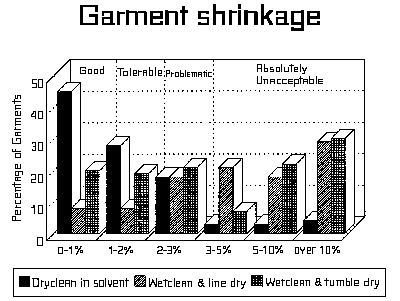

Typical Dry Cleaning Process

The walk-through and in-depth surveys of various commercial dry cleaning shops in the U.S. revealed that although practices varied from one shop to another, the overall dry cleaning process was similar. The typical process begins when garments are brought to the shop by customers or arrive by van from another “satellite shop,” which does no dry cleaning on site. Garments are initially tagged for identification. Prior to spotting or being loaded into the dry cleaning machine, garments are typically inspected and sorted according to weight, color, and finish. Modern garments are made from many different types of fabrics, and most drycleaners have the tools to clean all types.

Spotting

Particular attention was paid to spotting during the surveys to determine if excessive exposures occurred during this process. The spotting process might assume greater importance if wet cleaning methods in the U.S. were more widely used. Information was gathered prior to shop visits to determine which spotting chemicals a particular shop used most frequently. Purchasing records and Material Safety Data Sheets were reviewed.

In a typical shop, garments with visible stains are routinely treated at the spotting station. Spotting involves the selective application of a wide variety of chemicals and steam to remove specific stains from the garments. The three general categories of stains are water soluble, solvent soluble, and insoluble. Stains rarely consist of a single substance. Spotting chemicals and chemical mixtures are either solvent-based liquids (dryside) or water-based detergents (wetside). Wetside chemicals, which may contain water, remove water-soluble stains; and dryside chemicals, which never contain water, remove solvent-soluble stains.

The spotting chemicals, contained in small, plastic squeeze bottles, are applied to the stain. Spotting usually occurs on a spotting board equipped with pressurized air, steam, and water guns designed to flush the chemicals and stains from the garment. Air, steam, a small brush, a spatula, and fingers are all used to help break up the stains and wash them away. A pedal-actuated vacuum is used to capture the spotting chemicals, which are either held in a local storage reservoir or transported to a vacuum canister for discard.

In addition to PERC, some of the more common chemicals and chemical families for spotting are other chlorinated solvents, amyl acetate, petroleum naphtha, oxalic acid, acetic acid, esters, ethers, ketones, dilute hydrofluoric acid, hydrogen peroxide, and aqueous ammonia. Each of these chemicals are used in limited quantities. Most spotting chemicals are purchased from a company that supplies proprietary products to the industry. However, some shops use their own concoctions, which are prepared by individuals highly skilled in the art of stain removal.50

The spotting process has two components: pre-spotting, which involves dryside chemicals to remove or loosen solvent-soluble stains; and post-spotting, which utilizes wetside chemicals to remove water-soluble stains. Water-soluble stains, which may further set during the dry cleaning process, are pre-spotted before dry cleaning. Post-spotting is often used if the stain was not visible before dry cleaning, or if the stain was not completely removed after pre-spotting and dry cleaning. However, some shops utilize the more time-intensive post-spotting exclusively since many spots are removed during dry cleaning. Some spotting processes involve little use of tools; the solvent is simply squirted liberally on all the stains before the garments are cleaned in the machine.

Machine Cleaning

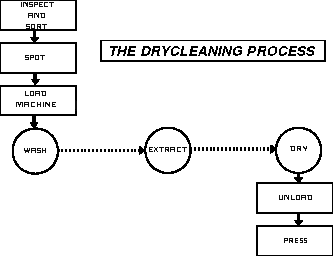

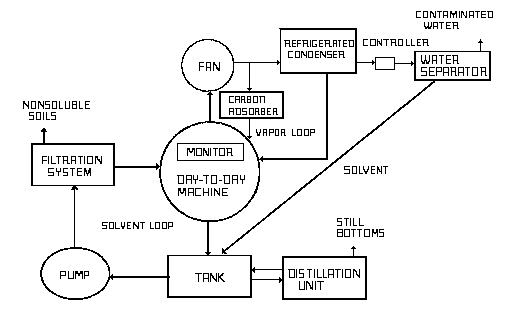

Dry Cleaning, a three-step process, involves washing, extracting, and drying. A diagram of this process can be seen in Figure 1. Before washing, a worker adds detergent to the solvent in one of two ways: 1) A charge detergent is added to the solvent in set concentrations. The charged solvent is re-used in successive loads, and fresh detergent is periodically added to maintain the proper detergent concentration. 2) Injection or no-charge detergent is added to each load, based on each load’s weight. Water is added to the system before or during dry cleaning and aids in removing water soluble soils from the fabric.

To begin washing, clothes are manually loaded into the machine, followed by the solvent. The contents of the machine are then agitated for a period of time, allowing the solution to remove soils. Next, the clothes are spun at a high speed to extract the solvent.

After extraction, the fabric is tumbled dry. The drying process may occur in the same machine or a different one, depending on the system. Recirculated warm air vaporizes the residual solvent. Unheated air is then passed through the system during the cool-down cycle. This step reduces wrinkles. Following cool-down in vented machines, fresh air is passed through the system to freshen and deodorize the clothing during the aeration step.27 Garments are then removed from the machine prior to pressing.

Figure 1.The dry cleaning process flow diagram

Drycleaners use filtration and/or distillation to recover and purify solvent. Filtration removes insoluble soils, nonvolatile residues, and loose dyes from the solvent and, in some cases, soluble soils. Filtration is usually a continuous process in which the solvent passes through either an adsorbent powder or filter cartridge, both needing periodic replacement. Additionally, new, powderless, spin-disc filters51 significantly reduce the generation of hazardous waste because they are regenerated instead of discarded.52

Distillation, used by 90% of the industry, removes soluble oils, fatty acids, and greases not removed by filtration. Dry Cleaning stills typically consist of a kettle, condenser, and separator. Distillation occurs by heating PERC to its boiling point. The PERC vaporizes and condenses back into a liquid form. During this process, nonvolatile impurities, which do not evaporate, remain at the bottom of the still and are discarded as hazardous waste. Both filtration and distillation produce solid wastes containing PERC.

Pressing

Pressing is generally a dynamic and repetitive task that requires reaching and precision gripping. Pressers usually stand at non adjustable workstations for much of the day and reach well overhead for hanging garments. When a garment is placed on a pressing machine, it is pressed between two surfaces, at least one of which is heated to a temperature around 149°C (300°F).

Some of the equipment used by pressers includes general utility presses; puff irons; pants toppers; finishers; electric irons; bosom, body, and yoke presses; collar, cuff, and yoke presses; and sleevers. Because this equipment is highly specialized, drycleaners do not necessarily have all of these presses. Once the garments have been completely pressed, they are returned to the overhead rack and wrapped in plastic for customer pick-up.

Dry Cleaning Machine Control Technologies

Shops included in the current NIOSH study were collectively selected to represent a cross-section of the controls available within the dry cleaning industry. The most important factor for site selection was the effectiveness of the control system for reducing exposures to PERC. The NIOSH study evaluated the primary working hypothesis that four general categories of dry cleaning machines were capable of maintaining an 8-hour TWA personal exposure to PERC of less than or equal to 25 ppm.

The four general categories of dry cleaning machines evaluated were:

- transfer machines

- vented and nonvented dry-to-dry machines

- machines with refrigerated condensers and/or carbon absorbers

- “fifth generation,” nonvented, dry-to-dry machines, having residual controls.

Two Basic Types of Dry Cleaning Machines

Two basic types of machines are generally used in dry cleaning: transfer and dry-to-dry. Transfer machines are older, less expensive, and require manual transfer of solvent-laden clothing between the washer and dryer, a source of high worker exposure. Dry-to-dry machines eliminate clothing transfer because items are processed in one step, entering and exiting the machine dry. Transfer machines process more clothing than comparably sized dry-to-dry machines because the process time is approximately half that of a dry-to-dry machine. To compensate, some owners of dry-to-dry machines reduce the cycle time, thereby increasing productivity. Such practices can also increase exposures that result from unevaporated residuals in the dry cleaned clothing.53

Transfer machines are generally vented, but dry-to-dry machines can be vented or nonvented. Vented dry-to-dry machines exhaust residual solvent vapors directly into the atmosphere or through some form of vapor recovery system, usually during the aeration process. Nonvented dry-to-dry machines are essentially closed systems, which are open to the atmosphere only when the machine door is opened. These machines recirculate the heated drying air through a vapor recovery system and back to the drying drum, eliminating the aeration step. Unfortunately, significant concentrations of PERC remain in the drum at the end of the cycle.

Approximately 70% of the dry cleaning machines found today in the U.S. are of the newer dry-to-dry design. Transfer machines are no longer manufactured in the United States because of the high solvent usage rate, emissions, and exposures during transfer. However, used or reconditioned transfer machines can still be purchased. Either PERC or petroleum-based solvents can be used in dry-to-dry or transfer machines, but PERC is the solvent of choice for the majority of U.S. drycleaners.

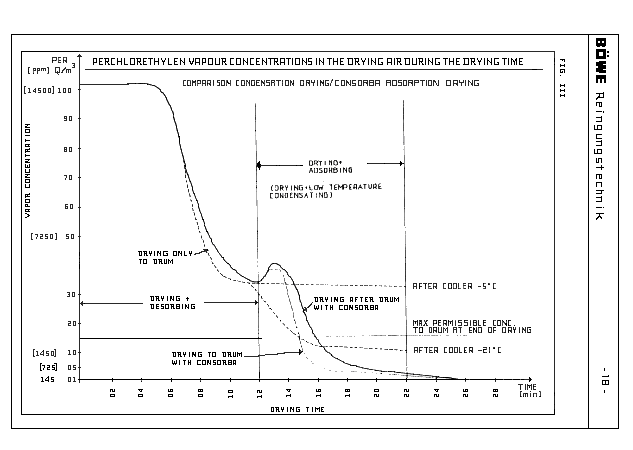

Two Primary Vapor Recovery Technologies

The two primary technologies used to recover PERC vapors from dry cleaning machines are the carbon absorber and the refrigerated condenser. Carbon absorbers are used in approximately 35% of controlled machines and refrigerated condensers, in approximately 65%. Carbon absorbers remove PERC molecules from the air by passing solvent-laden vapors over activated carbon with a high adsorption capacity. The carbon is then desorbed and the PERC recovered, or the carbon is discarded when saturated. Carbon desorption typically occurs with steam or hot air. Desorption can be done automatically after each load, at the end of the day, or it can be done at other intervals depending on the PERC concentration and amount of carbon. If not done regularly, the carbon bed will become saturated and ineffective.

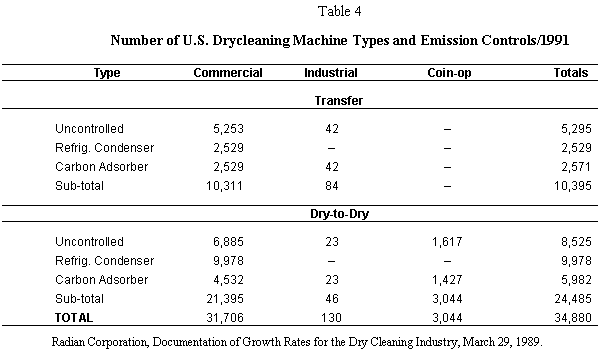

Refrigerated condensers use a refrigerant to cool the solvent-laden air below the dew point of the vapor to recover the PERC. The number of transfer machines using refrigerated condensers is roughly equivalent to the number of transfer machines using carbon absorbers. However, on dry-to-dry machines there are approximately twice as many refrigerated condensers in use (see Table 4).

Dry Cleaning Machine Types in the U.S.

In 1988, the International Fabricare Institute (IFI) conducted a national dry cleaning plant and equipment survey in which 5.8% of U.S. dry cleaners participated. Results of that survey indicated that 79% of the shops responding used PERC only, and another 9% of shops used PERC and another solvent. For all PERC dry cleaning machines, regardless of age, approximately 34% were dry-to-dry nonvented, 32% were dry-to-dry vented, and the remaining 34% were transfer machines. For PERC dry cleaning machines that were less than five years old at the time, approximately 62% were dry-to-dry nonvented, 31% were dry-to-dry vented, and 7% were transfer. The majority of PERC dry cleaning machines had a capacity of 30-39 lb, followed by 40-49 lb, and 50-59 lb, respectively. The average cleaning volume was 1,926 lb of clothing per week.54

The Evaluated Dry Cleaning Machines

During the six in-depth surveys conducted in various U.S. commercial dry cleaning shops, NIOSH investigators evaluated sources of emissions and exposures from machines in the four general categories given above. Descriptions of the specific dry cleaning equipment evaluated follow.

The Evaluated Transfer Dry Cleaning Machine.—The transfer unit studied consisted of two separate machines: a J & T® Model 60, 60-lb washer and a Model SF-145 Hoyt® Solvo-miser reclaimer. Both machines were over ten years old. The washer and reclaimer were connected to a Kleenrite® Vapor Condenser. The reclaimer had an internal, water-cooled condenser and separate refrigerated, vapor condenser. The reclaimer operated in three different modes: dry, cool, and aerate. During the dry mode, recirculated air was heated and then cooled in the condenser to recover PERC. During the cool mode, the air was diverted to the separate vapor condenser and cooled to recover PERC. During the final aeration cycle, fresh air was drawn into the reclaimer and exhausted outside of the building.

The Evaluated Dry-to-Dry, Vented Dry Cleaning Machine.—An Omega® Model CE55, 55-lb dry-to-dry machine, which was about six years old, was evaluated. This machine had a refrigerated condenser as the primary vapor recovery device. The secondary vapor recovery device consisted of a small, centrifugal fan rated at 110 cubic feet per minute (cfm) that was ducted to a carbon canister. When the machine door was opened, a microswitch energized the fan to draw PERC-laden air from the cylinder through the activated carbon.

The Evaluated Dry-to-Dry, Nonvented Machine.—Two nonvented, refrigerated, dry-to-dry machines, each less than five years old, were evaluated: a Boewe® Permac Model P540, 46-lb dry-to-dry machine and a Fluormatic® Model M242, 30-lb dry-to-dry machine. Both had a refrigerated condenser as the primary vapor recovery device. Both machines were connected to a Rite-Temp® Model RTR1003AWC Chiller used to chill water for reclamation, distillation, and maintenance of proper solvent temperature. There were no secondary vapor recovery devices.

Modern “Fifth Generation” Machine Technology.—Modern, dry-to-dry, nonvented dry cleaning machines with residual controls are commonly referred to as “fifth generation” machines. The design of “fifth generation” machines began in Germany where their use is now mandated primarily by the Second German Emission Standard. “Fifth generation” dry cleaning machines have engineering controls which dramatically reduce residual PERC in the machine’s cylinder at the end of the dry cycle. These closed-loop, dry-to-dry machines rely on both an integrated, refrigerated condenser and a large carbon adsorber to recover PERC vapors during the dry cycle. “Fifth generation” machines are much more effective at recovering solvent vapors while drying garments than are machines equipped with only a carbon adsorber or refrigerated condenser alone. They are capable of lowering the PERC concentration in the machine’s cylinder to below 290 ppm at the end of the dry cycle.

“Fifth generation” machines use a single beam, infrared photometer to monitor the PERC concentration in the machine cylinder. An interlock on the machine door prevents the operator from opening the machine door until the PERC concentration in the cylinder is below 290 ppm. The drying cycle will continue to operate until the cylinder concentration is sufficiently low. Such sophisticated machines are expensive and not widely used in the U.S.

Two Boewe Passat® dry-to-dry, nonvented dry cleaning machines with residual controls were evaluated. One machine was a model P546, 46-lb machine, and the other was a model P536, 36-lb machine. Both machines had an integrated, refrigerated condenser and a large regenerable carbon adsorber to recover PERC vapors during the dry cycle. These machines were designed to lower the PERC concentration in the machine cylinder at the end of the dry cycle. This was accomplished using a large carbon adsorption system to capture PERC in the airstream and a single beam infrared photometer to continuously monitor the PERC concentration in the machine cylinder. An interlock on the machine door prevented opening until the PERC concentration in the cylinder was sufficiently low. The machines had a cleaning cycle of 35 to 40 minutes; however, the drying cycle was often automatically extended to ensure that the PERC concentration in the cylinder was below 290 ppm. The operator could determine the PERC concentration in the cylinder by reading a printout from the infrared photometer. The emission-free, still-cleaning device required still-raking only once every three weeks. A dosing unit enabled the operator to perform garment waterproofing within the machine.

Methodology

The principle measurements in this study were air concentrations of PERC measured both with conventional air-sampling pumps with charcoal tubes, and real-time instruments.

Air Sampling

Personal, area, and background air sampling was conducted using NIOSH Method 1003 for PERC and other halogenated hydrocarbons. In this method, organic vapors were drawn through 100 mg/50 mg coconut shell charcoal tubes. Carbon disulfide was used to desorb the solvents from the charcoal tube. Analysis was done using a gas chromatograph, fitted with a flame ionization detector to determine PERC concentrations and, in some instances, to determine all halogenated hydrocarbons concentrations. Samples were collected over 120-minutes at a flow rate of 0.1 liters/minute and a volume of 12 liters. The limit of detection for this method is 0.01 mg/sample.55

Two-hour consecutive personal sampling was conducted on all of the machine operators, as well as on some of the spotters and pressers who worked in proximity to the dry cleaning machines. Two-hour consecutive samples were used to determine full-shift TWA exposures. The purpose of conducting personal sampling was to compare worker perchloroethylene exposures to a TWA of 25 ppm. In addition to TWAs, 5-minute and 15-minute exposures were measured during some manual tasks. This was done at a flow rate of 0.1 liters/minute and a volume of 0.5 and 1.5 liters respectively.

Area sampling determined which areas of the shop had the highest concentrations and were collected at various distances and locations around the periphery of the dry cleaning machine. Air samples were generally collected in front of and behind the dry cleaning machines, in the pressing area, in the spotting area, in the hazardous waste storage area, near the customer counter, and outside of the building. These locations were similar for each shop evaluated. This data helped in the development of strategies to reduce the exposures.

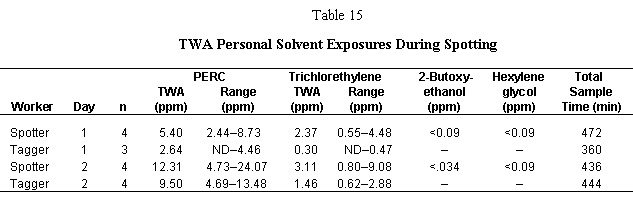

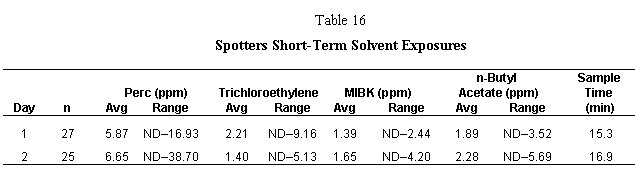

Air sampling was also used to evaluate the risk of chemical inhalation during the spotting process. Air sampling was conducted for two days to evaluate worker exposures to PERC, trichloroethylene, 2-butoxyethanol, hexylene glycol, MIBK, and n-butyl acetate. Additionally, five area samples were taken to determine concentrations of PERC and trichloroethylene. The ratio of equilibrium vapor concentration to TLV was used to compute a vapor/hazard ratio. Peak and 8-hour TWA personal sampling of spotters were conducted for halogenated hydrocarbons that could be sampled using NIOSH Method 1003. When combined exposures of PERC and other spotting chemicals were involved, the combined exposure (CE) was determined as follows.

CE = C1/T1+C2/T2+…+ Cn/Tn

Where:

Cn = Exposure to an individual contaminant (ppm)

Tn = The OSHA PEL for the individual contaminant (ppm)

If the value of CE is less than 1, the combined exposure is believed to be acceptable. When this calculation was used during the in-depth spotting evaluation, the OSHA PEL for each chemical was applied if available. For hexylene glycol, no OSHA PEL was available; therefore, the NIOSH ceiling of 25 ppm was used.

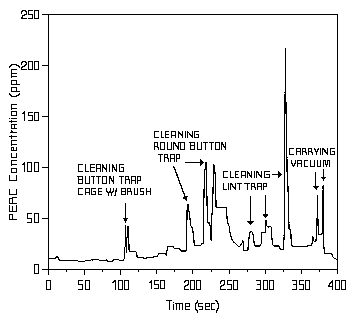

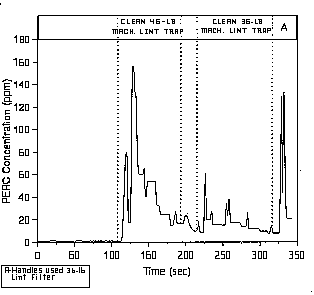

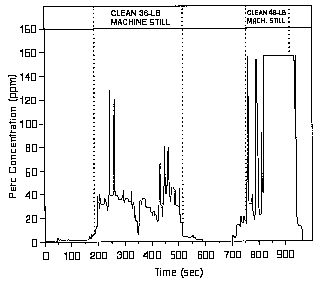

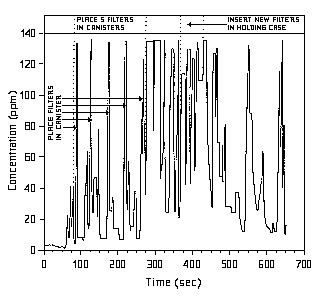

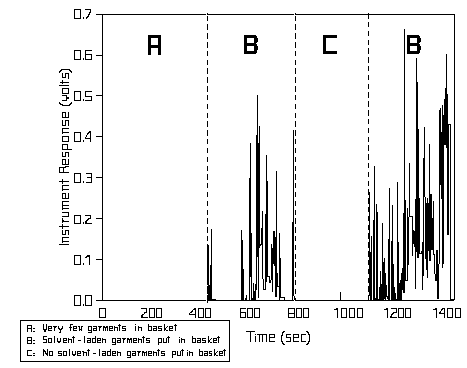

Real-Time Monitoring

Real-time monitoring was used to study how specific manual tasks and maintenance operations affected worker exposure to PERC. Some dry cleaning procedures occurred frequently throughout the day, such as loading/unloading the machine, while others, such as cleaning the lint and button traps, were less often. Most of these tasks took between 5 and 30 minutes. Real-time monitoring of PERC exposures were performed using a MicroTIP® IS3000® (PHOTOVAC Inc, Thornhill, Ontario) with a 10.6 EV ultraviolet lamp. This instrument uses a photoionization detector (PID) to provide an analog output response proportional to the concentration of ionizable chemicals present in the air. The MicroTIP® was spanned, using 100 ppm isobutylene span gas, and calibrated for both PERC and mineral spirits, using five standard concentrations of PERC vapor and mineral spirits vapor. Instrument readings and actual concentrations were used to construct two calibration curves and find predictive equations. The following formula was used to convert the output of the PID (volts) to concentration of contaminant (ppm):

C(t) = IR(t) * CF* MR

where:

C(t) = concentration of vapor at time t (ppm)

IR(t) = instrument response at time t (volts)

CF = conversion factor from calibration equation

MR = MicroTIP® range

Information gathered using the MicroTIP® was electronically recorded on a Rustrak® data logger (Rustrak® Ranger, Gulton, Inc., East Greenwich, RI) and downloaded to a portable computer, using Pronto® software. During the gathering of real-time data, a video camera recorded worker activities. This videotape permitted detailed analysis of tasks for quantitative determination of work activities causing the highest exposures.

Real-time monitoring was used for brief periods of time and focused on worker exposure during manual tasks and maintenance operations which might be related to high exposures. The frequency of manual tasks varied from shop to shop. Some common activities and their approximate frequencies follow:

Maintenance procedure Approximate frequency Still cleaning Daily Filter replacement Demand related Filling the tank Demand related Water separator Weekly maintenance Button/lint trap cleaning Daily

Specific questions addressed from real-time monitoring results included:

- p Are certain controls more effective at reducing exposures around cleaning and pressing stations?

- p Do specific actions result in higher exposures?

- p How does air contaminant concentration decay over time?

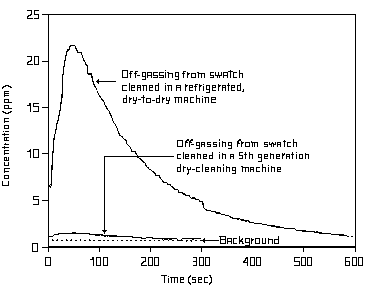

Real-time monitoring was also used to study off-gassing of garments and to compare vapor recovery efficiency of the machines. A standard test swatch, approximately 5 in. by 6 in. and made of 51% rayon and 49% polyester, was added to several runs of the dry cleaning machine. At the completion of the dry cycle, the test swatch was placed in a small glass test chamber. As the solvent residuals in the swatch vaporized, PERC concentrations were monitored and recorded, using the MicroTIP® and Rustrak® data logger. This method detailed garment off-gassing and provided continuous concentration profiles, which were used to quantitatively compare the vapor recovery system’s performance for each machine evaluated.

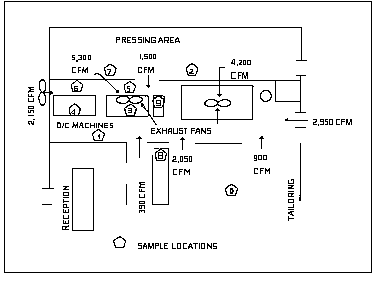

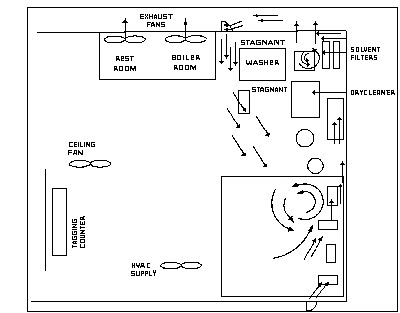

Evaluation of Ventilation Systems

Another aspect of this study was the evaluation of ventilation system performance. The various components of both the local and general ventilation systems were documented in order to assess the role of the entire ventilation system in controlling worker exposures. Data gathered during study of the ventilation system was compared to recommended values in the literature.

The following factors were examined when appropriate:

- p exhaust hood design, dimensions, and location

- p hood face velocity, capture velocity, and flow rate

- p airflow patterns and velocity around the source of exposure

- p system design specifications

A Kurz® Model 1440 Air Velocity Meter was used to measure air speed. Smoke tubes were used to qualitatively evaluate airflow patterns near the machine and within the building.

General dilution ventilation was evaluated at each dry cleaning shop studied. General ventilation can reduce contaminant concentrations in large areas that are not controlled locally. As part of the evaluation, a layout of the facilities was obtained, showing locations of exhaust ducts and makeup air. Flow rates, face velocities, and airflow patterns in the building were documented. All of the data gathered were compared to design specifications when possible.

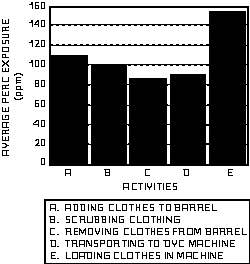

Ergonomic Evaluation

Hazards and risk factors present during the pressing operation were evaluated by examining work station design, anthropometry, and conducting time studies of the tasks performed. Based upon walk-through surveys, preliminary information indicated that high repetition/insufficient recovery time, and awkward postures might be risk factors present during pressing operations. Interaction of these and other risk factors have been shown to result in cumulative trauma disorders.35,55

Repetitiveness and recovery time were evaluated by examining cycle time. This was accomplished by videotaping and analyzing tasks in their elemental forms. Awkward and sustained postures performed during the pressing operation were examined to determine whether they were a problem in light of the general guidelines which can be found in the current literature. Each of the tasks were videotaped and measurements were made to determine height, reach, anthropometric envelope, and physical layout of the workstation.

Work Practice Observations

Because work practices often have a dramatic effect on exposures, observations recorded during site visits were an important aspect of this study. Of particular importance were activities related to loading/unloading the machines, maintenance procedures, pressing operations, spotting, and use of personal protective equipment.

Control of Dry cleaning Solvent Exposures

The following section gives results from the six in-depth dry cleaning surveys, discusses exposures and emissions, and suggests control options for U.S. commercial, dry cleaning shops. Information gathered during the WHO fellowship in Europe is included primarily in the sections addressing substitution and “fifth generation” dry cleaning machines.

Sampling and Monitoring Results

Air Sampling

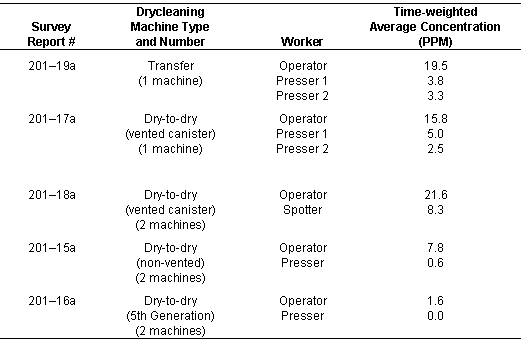

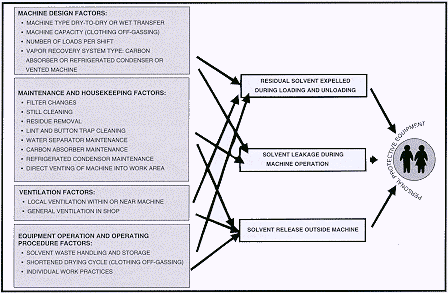

Results of personal air sampling can be seen in Table 5. Generally, air samples gathered near the dry cleaning machine had higher PERC concentrations than those farther away from the machine. Similarly, the more time a worker spent near the dry cleaning machine, the higher the PERC exposures tended to be. Those dry cleaning machines that were designed to lower the PERC concentration, emitted from the machine cylinder, were more effective than traditional machines at reducing worker exposures. Operators received the highest exposures from loading and unloading the machine; whereas, pressers were primarily exposed from garment off-gassing.

Table 5: Time-Weighted Average Worker Exposures to PERC (for entire survey)

Transfer Equipment.—All but one of the daily TWA personal samples taken on the transfer machine operator and two pressers were below 25 ppm. The transfer machine operator was exposed to 19.5 ppm TWA PERC for the entire survey. The operator’s two-hour samples ranged from 3.9 to 42.3 ppm. The two pressers, who did not work in as close proximity to the transfer machine as the operator, were exposed to 3.3 and 3.8 ppm TWA PERC during the entire survey. Statistical analysis showed a significant difference between the operator’s and pressers’ TWA exposures.

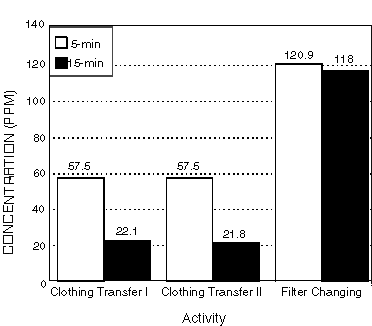

NIOSH investigators gathered 5- and 15-minute personal air samples on charcoal tubes during transfer operations and filter changing (Figure 2). Neither of these activities exceeded the OSHA ceiling of 200 ppm or OSHA peak of 300ppm. Exposure during transfer operations was 57.5 ppm for a 5-minute period and 21 to 22ppm during a 15-minute period. The reason for the differences between 5- and 15-minute concentrations was due to time taken for tasks. Exposure during filter changing was approximately 121 ppm for 5minutes and 118 ppm for 15 minutes.

Figure 2. Five-minute and fifteen minute personal exposures to PERC from transfer equipment.

The highest area concentrations were above the reclaimer door. The geometric mean concentration in that area was 15.2 ppm, which was significantly different from all other areas. It seems logical that these area concentrations would have been the highest because the air was heated, and the PERC was in the vapor state during loading/unloading the reclaimer, but the solvent and air in the washer were not heated.

Dry-to-Dry, Vented Equipment.—All of the individual personal samples taken for the dry-to-dry, vented machine were below 25 ppm. The machine operator was exposed to 15.8 ppm TWA PERC for the entire survey. Two-thirds of these exposures resulted from loading and unloading the machine. The two pressers were exposed to 5.0 and 2.5 ppm TWA PERC for the entire survey. The highest geometric mean area concentrations measured, 9 and 12 ppm PERC, were near the dry cleaning machine where a vapor leak was detected. The next highest geometric mean concentrations, 6 and 8 ppm PERC, were above the machine door.

Dry-to-Dry, Nonvented Equipment.—The machine operator, a presser, and a clothing inspector were sampled at the shop having two nonvented dry-to-dry machines, and all individual personal samples were below 25 ppm. The machine operator was exposed to 7.8 ppm TWA PERC for the entire survey. Nearly half of this exposure resulted from loading and unloading. The presser and inspector were exposed to less than 1 ppm TWA PERC. The highest area samples, 5.4 and 5.7 ppm PERC, were taken above the dry cleaning machines’ doors. The next highest concentrations were behind the machines.

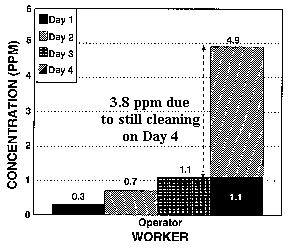

Dry-to-Dry, Nonvented with Residual Control.—Figure 3 summarizes personal air samples gathered for the two dry-to-dry, nonvented machines with residual controls. All of the personal samples were well below 25 ppm and were dramatically lower than exposures on any other machines evaluated. The operator of the “fifth generation” machine had the highest exposure to PERC, ranging from 0.31 to 4.9 ppm TWA. Almost all of the operator two-hour samples were below 2ppm PERC, and most samples were below 1 ppm. The only exception to these low exposures occurred when the operator raked the still bottoms of both machines. During the last morning of sampling, the operator was exposed to approximately 12 ppm over a two-hour period and 4.9 ppm full-shift TWA PERC primarily because of cleaning the stills. If the stills had not been cleaned, the TWA exposure probably would have been less than 2 ppm.

Figure 3. Time-weighted average worker exposure to PERC from “fifth generation” dry cleaning machines. (Four days of air sampling.)

The pressers were protected from PERC vapors originating from the machine by ventilation and barriers between the pressing station and dry cleaning machine. All of the PERC concentrations measured near the presser’s breathing zone were at or below the limit of detection, 0.01 mg/sample. This minimal exposure resulted from almost no PERC retention in the clothing. Little PERC was detected on samples outside of the dry cleaning room. This nondetection of PERC can be attributed to excellent machine design and ventilation near the machines. The highest area concentrations, ranging from 0.0 to 1.9 ppm, were detected above and behind the dry cleaning machines.

Statistical Analysis of Air Sampling Data

Summaries of the personal air sample results and their statistical analysis are in Tables 5, 6, 7, and 8. All of the TWA and mean exposures to PERC in these tables were below 25 ppm. However, some of the individual two-hour samples exceeded 25 ppm, and so did a small number of the daily TWA exposures. Time-weighted average exposures would have been somewhat lower if sampling had occurred for a full 8-hour shift; however, air sampling generally occurred when the dry cleaning machines were in operation, typically six or seven hours per day.

Statistical analysis was performed on log transformed air sampling data for PERC. A two-way analysis of variance (ANOVA) showed that job title and shop had a significant effect upon concentration (p<0.0001). A multiple comparison test with 5% significance level, least significant difference (LSD), was used to analyze concentration differences.

Table 5 gives the TWA personal air samples by job for each shop evaluated. The TWA exposures in the table are for the duration of the entire survey. At each shop evaluated, the machine operator had consistently higher exposures than did any other job title. Most of the workers performing other jobs were exposed to less than one-third of the machine operator’s exposure. Much of the difference can be attributed to the fact that the other jobs did not include the peak exposures associated with loading and unloading the machine.

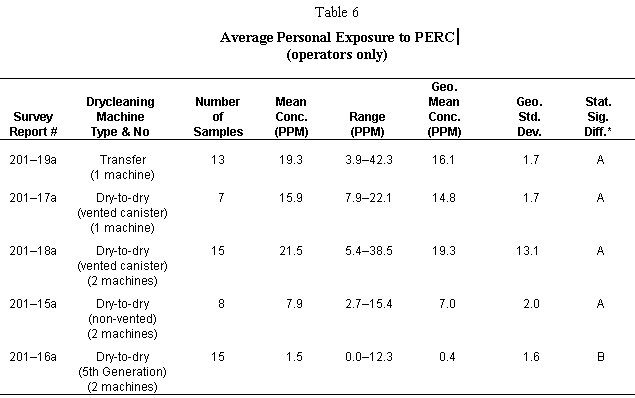

Table 6 provides arithmetic and geometric mean personal exposures to PERC by shop for machine operators and the results of the two-way analysis of variance (2-WAY ANOVA). It also includes the concentration range and geometric standard deviation. This statistical analysis indicates that the operator of the advanced, “fifth generation” dry cleaning machines was exposed to significantly lower PERC concentrations than operators of any other type of machine. Differences between operator exposures at all other shops were not statistically significant.

*Different letters indicate a statistically significant difference using the least significant difference test. (Α = .05)

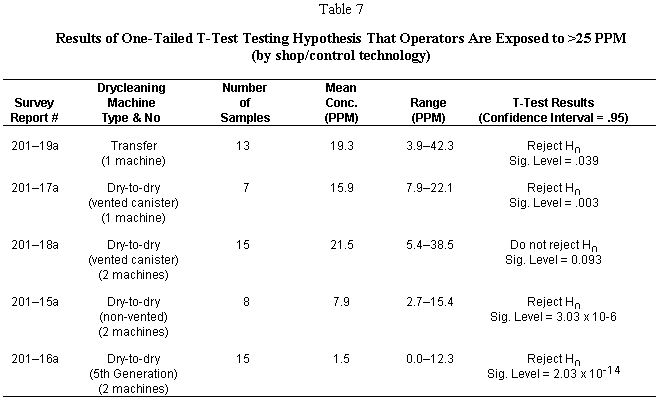

Table 7 gives the results of a one-tailed (Α = 0.05) t-test, comparing operator exposure to PERC at each shop evaluated to 25 ppm. All of the machines studied maintained operator exposures to PERC below 25 ppm with the exception of the shop having two dry-to-dry, vented machines. Another shop with similar equipment, but only one machine, was able to control exposures below 25 ppm. Part of this difference may be due to production volume; this shop had two machines and a higher volume of garments, which required machine loading/unloading nearly twice as often.

Statistically significant at (Α = .05)

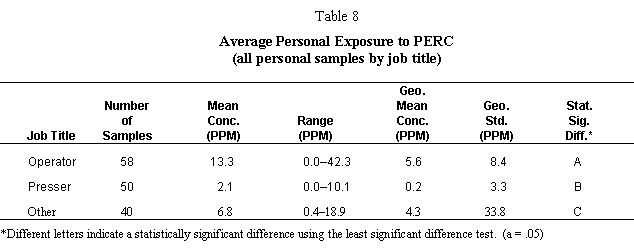

Table 8 is a summary of personal exposures to PERC by job title across shops. As expected, the machine operator had the highest mean exposure to PERC, which was 13.3 ppm for all shops evaluated. The machine operators’ exposures were significantly different from exposures experienced by pressers or “other” workers. The bulk of operator exposures resulted from loading/unloading the machine, or in some cases from transferring garments. The next highest mean exposure by job title, 6.8 ppm, occurred in a group of workers labeled as “other.” This group included workers who were not full-time operators or pressers. Finally, the pressers from all of the shops studied were exposed to the lowest mean concentration, 2.1 ppm.

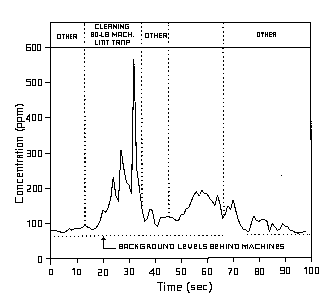

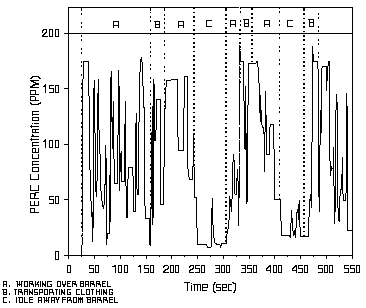

Real-Time Monitoring

Results of real-time analysis tended to support the air sampling results. Real-time results gave further insight into the reason why exposures from one type of machine were lower than exposures from another machine. The most significant source of PERC exposure occurred during loading/unloading the machines and garment transfer. Loading the machine frequently resulted in concentrations as high as or higher than unloading the machine due to air displacement. This was because of large quantities of PERC contaminated air being forced from the machine when dirty garments were loaded. Since high peak exposures occurred during these activities, the frequency of machine loading, unloading, and transfer played an important role in affecting total exposure. Exposure sources other than those directly from the machine, such as garment off-gassing and pressing, were substantially lower than exposures that occurred directly from the machine.

Transfer Equipment.—Figure 4 shows real-time data during garment transfer, loading the washer, and hanging the garments. Exposures during loading and unloading reached instantaneous concentrations between 1,000 and 1,500 ppm. The highest average exposures, 500-600 ppm, occurred during garment transfer from the washer to the reclaimer. The next highest average exposures occurred during loading the washer, unloading the reclaimer, and hanging clothing, respectively. Based on a comparison of real-time and air sampling results, over one-half of the operator’s exposure resulted from loading/unloading the machine and garment transfer. A comparison of unloading the reclaimer, transfer, and loading the washer indicated that transfer generally occupied more time. After the garments were dried, hanging the garments took even more time than other tasks, but the average exposure during handling was relatively low, 14-21 ppm. Some of the bulkier garments, which retained solvent and took longer to dry, resulted in instantaneous PERC exposures near 70 ppm.

Figure 4. Operator exposure to PERC during clothing transfer, loading washer, and hanging clothing.

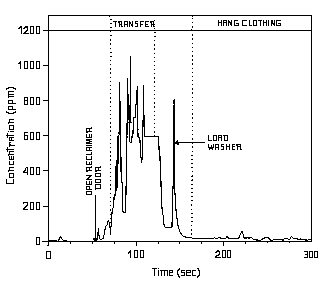

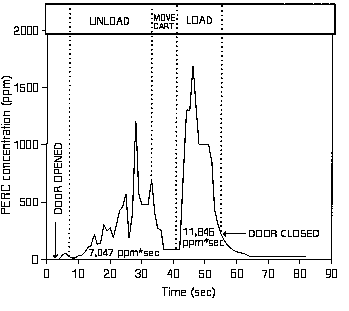

Dry-to-Dry, Vented Equipment.—The process of unloading took nearly twice as long as loading. Real-time monitoring (Figure 5) showed that average PERC exposure during loading was much higher than unloading the cleaned garments. The average exposure during loading was 846 ppm; average exposure during unloading was 271 ppm. The integrated exposure (area under the curve) was also higher during loading the machine, approximately 11,850 ppm*sec. versus 7,050 ppm*sec. Real-time measurements near the carbon canister on the top of the machine indicated that concentrations of PERC (approximately 1,500 ppm) were blown into the work environment each time the machine door was opened (Figure 6).The carbon canister was ineffective at capturing PERC in the exhausted air.

Figure 5. Operator exposure to PERC from a dry-to-dry, vented dry cleaning machine during unloading/loading.

Figure 6. Real-time measurements of PERC concentration near carbon canister exhaust of a dry-to-dry, vented dry cleaning machine.

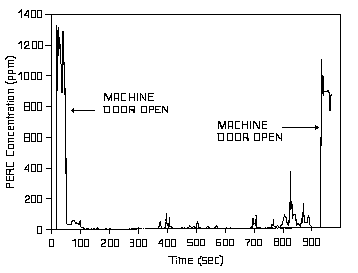

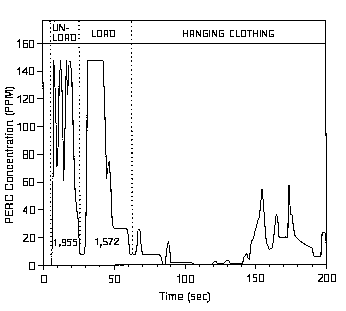

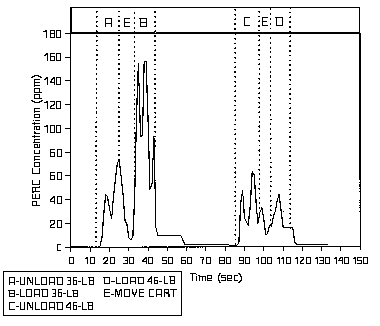

Dry-to-Dry, Nonvented Equipment.—Concentrations during loading/unloading were higher than any other activity; however, the instrument used to conduct real-time monitoring in the present NIOSH study became saturated and did not read the highest concentrations. This was because the maximum concentration the instrument was capable of reading was 156 ppm. Real-time measurements taken by NIOSH researchers at other shops using dry-to-dry, nonvented machines were approximately 1,500 to 2,000 ppm during machine loading and unloading. Figure 7 gives operator exposure during loading and unloading a machine and hanging clothing. The tops of the largest peaks are truncated because of the upper limit of the real-time detector. The larger machine generally took longer to unload than the smaller machine. Hanging the clothing took approximately 9 minutes. For both machines, the average PERC exposure while loading the machine with dirty clothing was almost the same as unloading garments cleaned in PERC. The similar exposures were caused by PERC contaminated residual air being forced from the cylinder while the door was opened to admit unclean clothing.

Figure 7. Operator exposure to PERC from a dry-to-dry, nonvented dry cleaning machine during loading, unloading, and hanging clothing.

When the 46-lb machine was loaded/unloaded, the integrated exposure to PERC was higher during unloading (1,955 ppm-sec. vs. 1,572 ppm-sec.); however, the average exposure was actually higher during loading (98 ppm vs. 89 ppm). The difference is made more profound through an examination of the median exposure during loading (147 ppm) versus unloading (98 ppm). Average exposure from loading and unloading the 30-lb machine was slightly higher than that from the 46-lb machine. There are two factors at work here: less efficient solvent recovery from the 30-lb machine and better local ventilation near it. Average exposure while hanging the clothing was approximately 5 ppm. The operator was exposed to higher PERC concentrations when hanging bulky items, which had not completely dried.

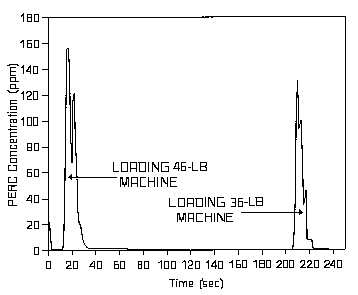

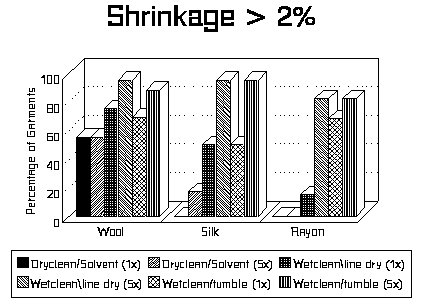

Dry-to-Dry, Nonvented with Residual Control.—Although these full-shift, TWA exposures were lower than at other shops, the greatest source of operator exposure from “fifth generation” machines continued to be from loading and unloading the machines. Exposures during this procedure peaked at approximately 160 ppm, which is an order of magnitude lower than most peak exposures at shops using different types of machines.