|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

||||

| ||||||||||

|

|

|

|

|

Persons using assistive technology might not be able to fully access information in this file. For assistance, please send e-mail to: mmwrq@cdc.gov. Type 508 Accommodation and the title of the report in the subject line of e-mail. Engineering and Public Health at CDCG. Scott Earnest, PhD,1 Laurence D. Reed,

MS,2 D. Conover, PhD,1 C. Estill,

MS,2 C. Gjessing, MS,1 M. Gressel,

PhD,1 R. Hall, MS,1 S.

Hudock, PhD,1 H. Hudson,

MPH,1 C. Kardous, MS,1 J. Sheehy,

PhD,1 J. Topmiller, MS,1 D. Trout,

MD,2 M. Woebkenberg, PhD,1 A. Amendola,

PhD,3 H. Hsiao, PhD,3 P. Keane,

MBA,3 D. Weissman, MD,4 G. Finfinger,

PhD,5S. Tadolini, PhD,5 E. Thimons,

MS,5 E. C.ullen, PhD,6 M. Jenkins,

MS,6 R. McKibbin,6 G. Conway,

MD,7 B. Husberg, MPH,7 J. Lincoln,

PhD,7 S. Rodenbeck, PhD,6 D. Lantagne,

MS,7 J. Cardarelli, II, PhD8

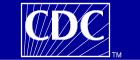

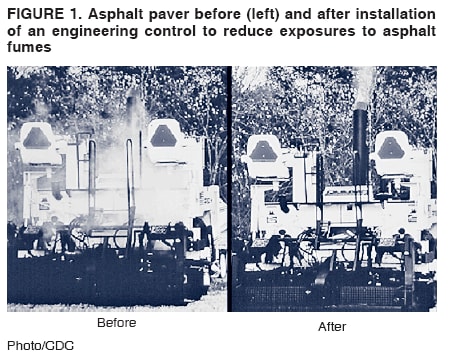

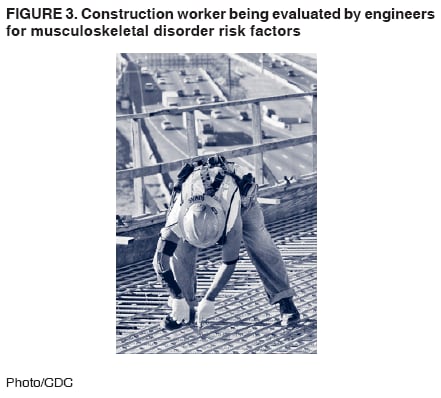

Corresponding author: G. Scott Earnest, PhD, Division of Applied Research and Technology, National Institute for Occupational Safety and Health, CDC, 4676 Columbia Parkway, Cincinnati, OH 45226. Telephone: 513-841-4539; Fax: 513-841-4506; E-mail: gearnest@cdc.gov. IntroductionEngineering is the application of scientific and technical knowledge to solve human problems. Using imagination, judgment, and reasoning to apply science, technology, mathematics, and practical experience, engineers develop the design, production, and operation of useful objects or processes. During the 1940s, engineers dominated the ranks of CDC scientists. In fact, the first CDC director, Assistant Surgeon General Mark Hollis, was an engineer. CDC engineers were involved in malaria control through the elimination of standing water. Eventually the CDC mission expanded to include prevention and control of dengue, typhus, and other communicable diseases. The development of chlorination, water filtration, and sewage treatment were crucial to preventing waterborne illness. Beginning in the 1950s, CDC engineers began their work to improve public health while developing the fields of environmental health, industrial hygiene, and control of air pollution (1). Engineering disciplines represented at CDC today include biomedical, civil, chemical, electrical, industrial, mechanical, mining, and safety engineering. Most CDC engineers are located in the National Institute for Occupational Safety and Health (NIOSH) and the Agency for Toxic Substances and Disease Registry (ATSDR). Engineering research at CDC has a broad stakeholder base. With the cooperation of industry, labor, trade associations, and other stakeholders and partners, current work includes studies of air contaminants, mining, safety, physical agents, ergonomics, and environmental hazards. Engineering solutions remain a cornerstone of the traditional "hierarchy of controls" approach to reducing public health hazards (2). Key Engineering Contributions to Public HealthAir ContaminantsCDC engineers at NIOSH Hamilton Laboratories have worked in industrial ventilation, isolation and containment, contaminant control, indoor environmental quality, and computational fluid dynamic modeling. Successful engineering-control studies have led to advancements for 1) controlling air contaminants, such as asphalt fumes, silica, and lead; 2) developing strategies under national emergency preparedness to protect buildings from attacks by chemical, biologic, or radiologic agents (3); 3) preventing transmission of infectious diseases in occupational settings (4,5); and 4) controlling carbon monoxide on recreational boats (6). CDC engineering work has focused on innovative solutions for controlling air contaminants. During the mid-1990s, NIOSH engineers, working with paving equipment manufacturers, designed a control that reduced worker exposure to asphalt fumes by 80% (Figure 1) (7). NIOSH engineers have studied control of respirable silica dust in nearly a dozen industries---in one example, employee exposure to respirable silica dust was reduced approximately 87% after a china manufacturing plant implemented its dust-control recommendations. CDC engineers at NIOSH also have designed studied, and had installed ventilated booths for radiator repair shops, reducing blood lead levels of workers in those shops by 70%. Lung-Function TestingCDC engineers have contributed substantially to the practice of lung-function testing. Accomplishments include development of the standard approaches to testing lung-function equipment; international leadership in developing and disseminating lung-function testing standards; and collaborations with epidemiologists in studies of occupational and general populations. A notable collaboration between NIOSH and the CDC National Center for Health Statistics led to development of a commonly used set of reference values for evaluating spirometry in the United States (8). MiningMining presents a challenging work environment; concerns include excessive noise levels, dust exposures, explosive and toxic gases, and massive equipment in near-constant motion. The NIOSH mining research program developed engineering controls for surface and underground mining to improve miners' health and safety. Successful controls adopted within the mining industry include water-jet sprays for dust control, noise reductions on conveyors and drill units, roof and structural support systems, designs for improved ventilation, mine-escape operations, and improved materials-handling systems. The mining community has successfully implemented products resulting from engineering research. These products include several programs that helped improve roof, floor, and sidewall stability and prevent the likelihood of roof collapse and major causes of death and injuries (9). Coal pillar recovery guidelines and mobile roof supports have made pillar recovery safer (10). Guidelines for designing deep-cover mines to prevent coal bumps (violent failures of highly stressed coal) contributed to 7 consecutive years without fatalities. A research and education campaign on rock-fall injuries and use of surface controls in coal mines has reduced rock-fall injury rates by approximately 25%. SafetyCDC engineers at NIOSH conduct safety engineering research to prevent occupational injuries by developing practical products and interventions in areas such as fall prevention, machine safety, and equipment safety research. Examples of engineering-control research include improved lock-out devices for paper balers and rollover protective structures for tractors, equipment responsible for numerous deaths and injuries. More rigorous standards have been examined for machine safeguarding, to better match international standards (11). Other projects include improving the safety of roof-bracket assemblies to protect roofers and construction workers from disabling or deadly falls (12) and developing improved work practices and computer modeling on scissor-lift tip-over controls to prevent fatalities. NIOSH safety engineers also study personal protective equipment for workers exposed to fall-from-elevation hazards (13). Research on the interface between the human body, machinery, and protective equipment represents an advancing area of safety engineering. These practices have provided the basis in developing injury-control innovations and moved many safety engineering technologies to product-design practices, standardization, and commercialization. NIOSH engineers and epidemiologists worked together in Alaska after deck machinery on commercial fishing vessels was identified as the cause of 40% of injuries requiring hospitalization in one of the country's most dangerous industries. Engineering researchers developed a solution to prevent entanglements from a capstan-style deck winch. Fishermen praised the device as a safety and productivity improvement that reduces injuries and work stoppages (14). Physical Agents: Noise, Heat, and RadiationHearing loss prevention engineers at CDC study the effects of noise-induced hearing loss that affects an estimated 30 million U.S. workers. Engineers design and develop instruments and methods to assess and characterize hazardous noise exposures. NIOSH engineers have an international reputation for their work on hearing protection devices, controlling exposure to impulsive noise, and novel engineering noise-control research. They developed and patented EarTalkTM, a hearing-protection and communication system that enables workers to communicate in noisy environments (Figure 2). They also developed a novel system for characterizing exposure to impulsive noise and applied for U.S. and international patents (15,16). Engineering assessments have shown that workers are exposed to ionizing radiation from technologies recently developed to improve homeland security. These technologies (many of which were introduced to market after the terrorist attacks of September 11, 2001) use X-rays to screen checked baggage at every major airport throughout the world for explosive materials or use gamma radiation to screen cargo containers for illegal contraband. NIOSH engineers characterized unnecessary exposures from these technologies and recommended measures to prevent or reduce these exposures (17). ErgonomicsEngineers support the NIOSH program to reduce work-related musculoskeletal disorders and contribute to the design of new or improved exposure-assessment techniques, tools, and equipment. According to the Bureau of Labor Statistics, approximately 32% of lost workdays result from overexertion or repetitive motion. CDC engineers developed an exposure-assessment technique to quantify risk factors associated with workplace postures and job tasks. Workers using nonpowered hand tools have been studied using force sensor technology to identify the portion of the work cycle resulting in the greatest forces to the hand. Effective interventions and solutions that reduced repetitive motion injuries have been applied to the agriculture, shipyard, mining, and construction industries (Figure 3). NIOSH also conducted an intervention trial that demonstrated a strategically designed patient-lifting program can markedly reduce musculoskeletal injuries to nursing staff in health-care facilities. CDC engineers at NIOSH worked to produce patentable devices to address specific concerns when commercially available interventions were not available (18--20). EnvironmentEngineers at ATSDR are involved in determining, through engineering interpretation of environmental investigations and sampling results, how the public could be exposed to hazardous materials in the environment. In addition, situation-specific sampling methodologies have been developed to determine how exposures have occurred to hazardous materials. Cutting-edge environmental modeling techniques are used to reconstruct past exposures from contaminated drinking water supplies. These remodeling techniques permit more accurate determination of adverse health impacts and reduce the exposure misclassification bias in ATSDR epidemiologic studies. During emergency response situations, ATSDR engineers analyzed community infrastructures to help determine when the public could safely return home (21,22). Water quality is a public health concern worldwide. CDC engineers at the National Center for Infectious Diseases, working with epidemiologists, have conducted water quality testing, developed standardized chlorine-dosing regimens, and collaborated to develop regional safe-water systems that are inexpensive and easy to transport and have the appropriate chlorine dosing. Engineering design has increased the impact of this program by making the chlorine solution available at lower cost to more persons in developing countries. Last year, 8 billion liters of water were treated in 15 countries throughout Africa and Asia. ConclusionsFor decades, CDC engineers have played a key role in enhancing U.S. and international public health by focusing on CDC goals concerning healthy communities, workplaces, homes, and schools. CDC engineers are meeting public health challenges by conducting laboratory and field studies, overseeing research and development that result in solutions-based products, conducting disaster relief and emergency response, and engaging in public health program management. Engineers are an integral part of the public health team that helps define what is possible, identify existing limitations, and shape workable solutions. Their efforts have contributed immensely to reducing disease and preventing injury in the United States and around the world. References

Figure 1  Return to top. Figure 2  Return to top. Figure 3  Return to top.

Disclaimer All MMWR HTML versions of articles are electronic conversions from ASCII text into HTML. This conversion may have resulted in character translation or format errors in the HTML version. Users should not rely on this HTML document, but are referred to the electronic PDF version and/or the original MMWR paper copy for the official text, figures, and tables. An original paper copy of this issue can be obtained from the Superintendent of Documents, U.S. Government Printing Office (GPO), Washington, DC 20402-9371; telephone: (202) 512-1800. Contact GPO for current prices. **Questions or messages regarding errors in formatting should be addressed to mmwrq@cdc.gov.Date last reviewed: 12/18/2006 |

|||||||||

|